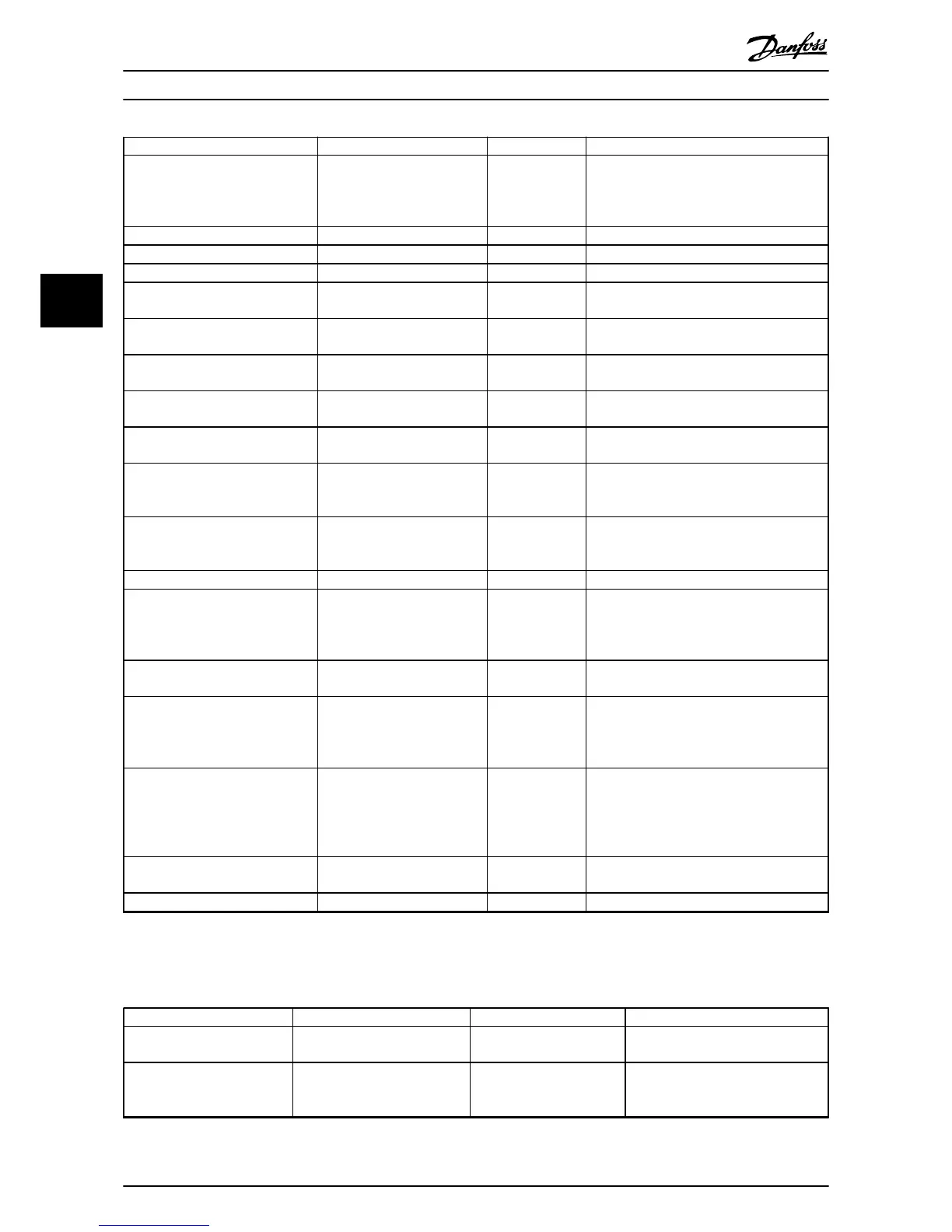

Parameter Range Default Usage

3-42 Ramp 1 Ramp Down Time

0.05–3600.0 s Size related

Ramp down time from rated 1-23 Motor

Frequency to 0 if asynchron motor is selected;

ramp down time from 1-25 Motor Nominal

Speed to 0 if PM motor is selected.

4-12 Motor Speed Low Limit [Hz]

0–400 Hz 0.0 Hz Enter the minimum limit for low speed.

4-14 Motor Speed High Limit [Hz]

0–400 Hz 100 Hz Enter the minimum limit for high speed.

4-19 Max Output Frequency

0–400 Size related Enter the maximum output frequency value.

6-29 Terminal 54 mode

[0] Current

[1] Voltage

1 Select if terminal 54 is used for current- or

voltage input.

6-20 Terminal 54 Low Voltage

0–10 V 0.07 V Enter the voltage that corresponds to the low

reference value.

6-21 Terminal 54 High Voltage

0–10 V 10 V Enter the voltage that corresponds to the low

high reference value.

6-22 Terminal 54 Low Current

0–20 mA 4 Enter the current that corresponds to the high

reference value.

6-23 Terminal 54 High Current

0–20 mA 20 Enter the current that corresponds to the high

reference value.

6-24 Terminal 54 Low Ref./Feedb.

Value

-4999–4999 0 Enter the feedback value that corresponds to

the voltage or current set in 6-20 Terminal 54

Low Voltage/6-22 Terminal 54 Low Current.

6-25 Terminal 54 High Ref./Feedb.

Value

-4999–4999 50 Enter the feedback value that corresponds to

the voltage or current set in 6-21 Terminal 54

High Voltage/6-23 Terminal 54 High Current.

6-26 Terminal 54 Filter Time Constant

0–10 s 0.01 Enter the filter time constant.

20-81 PI Normal/ Inverse Control

[0] Normal

[1] Inverse

0

Select [0] Normal to set the process control to

increase the output speed when the process

error is positive. Select [1] Inverse to reduce

the output speed.

20-83 PI Start Speed [Hz]

0–200 Hz 0 Enter the motor speed to be attained as a

start signal for commencement of PI control.

20-93 PI Proportional Gain

0–10 0.01 Enter the process controller proportional gain.

Quick control is obtained at high amplifi-

cation. However if amplification is too great,

the process may become unstable.

20-94 PI Integral Time

0.1–999.0 s 999.0 s Enter the process controller integral time.

Obtain quick control through a short integral

time, though if the integral time is too short,

the process becomes unstable. An excessively

long integral time disables the integral action.

30-22 Locked Rotor Detection

[0] Off

[1] On

[0] Off –

30-23 Locked Rotor Detection Time [s]

0.05–1 s 0.10 s –

Table 4.5 Set-up Wizard for Closed Loop Applications

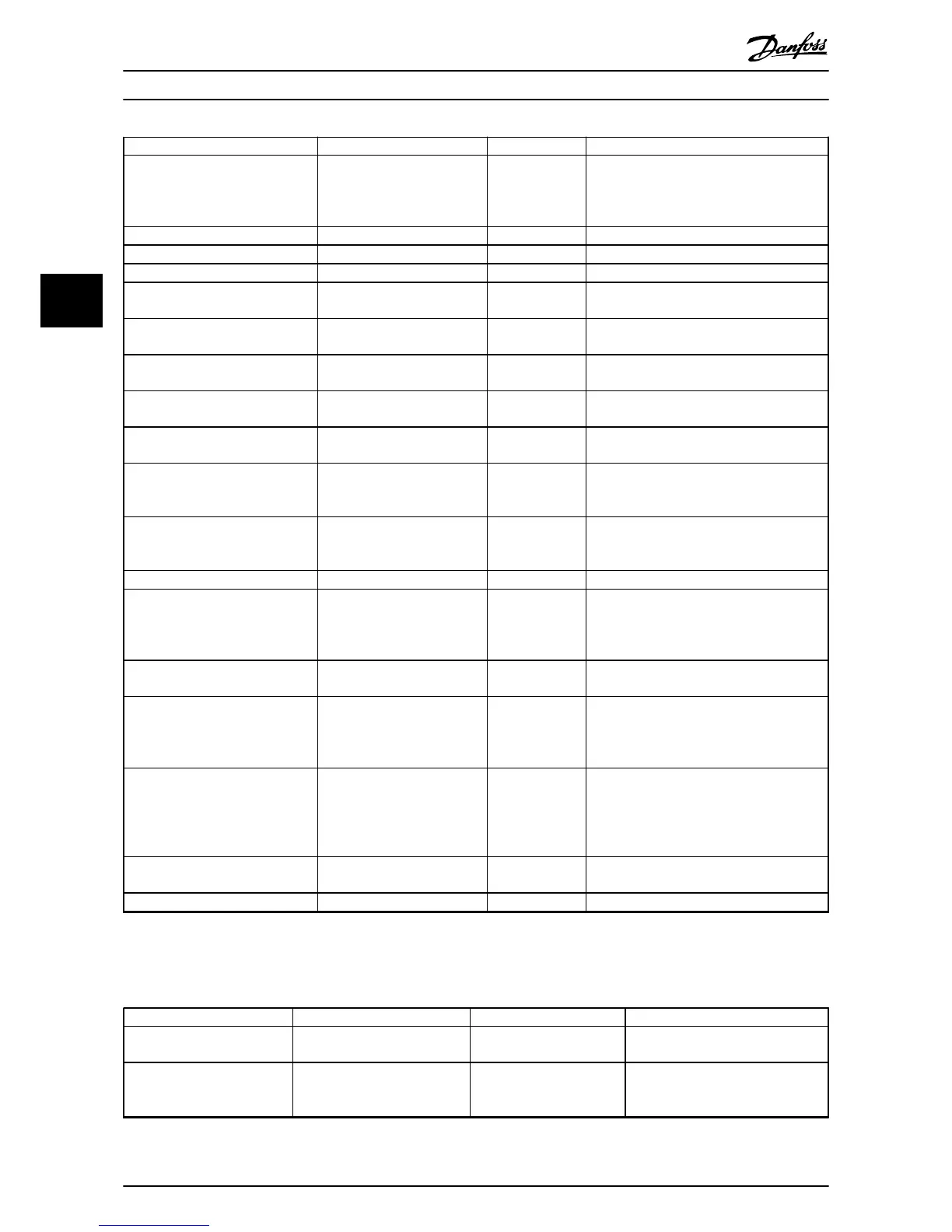

Motor set-up

The Motor Set-up wizard guides through the needed motor parameters.

Parameter Range Default Usage

0-03 Regional Settings

[0] International

[1] US

0 –

0-06 GridType

[0] -[132] see start -up wizard for

open loop application

Size selected Select the operating-mode for restart

upon reconnection of the drive to

mains voltage after power down.

Programming Quick Guide

34 Danfoss A/S © 08/2014 All rights reserved. MG18A602

44

Loading...

Loading...