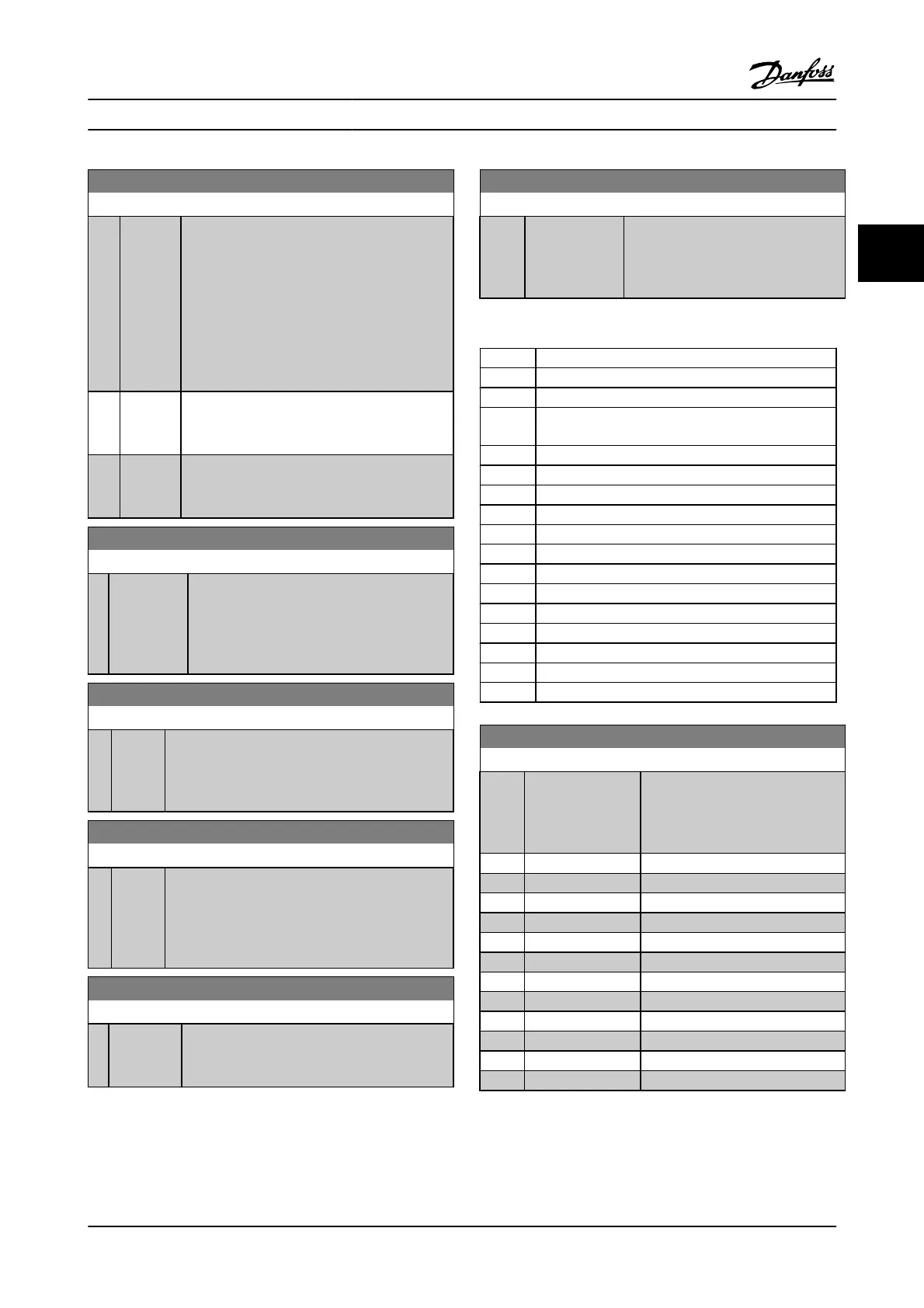

9-28 Process Control

Option: Function:

Process control (setting of the control word, speed

reference, and process data) is possible via either

Profibus or standard serial communication bus

but not both simultaneously. Local control is

always possible via the LCP. Control via process

control is possible via either terminals or serial

communication bus depending on the settings in

8-50 Coasting Select to 8-56 Preset Reference

Select.

[0] Disable Disables process control via Profibus, and enables

process control via standard serial communication

bus or Profibus Master class 2.

[1]

*

Enable

cyclic

master

Enables process control via Profibus Master Class

1, and disables process control via standard serial

communication bus or Profibus Master class 2.

9-44 Fault Message Counter

Range: Function:

0

*

[0 - 65535 ] This parameter displays the number of error

events stored in 9-45 Fault Code and 9-47 Fault

Number. The maximum buffer capacity is eight

error events. The buffer and counter are set to 0

upon reset or power-up.

9-45 Fault Code

Range: Function:

0

*

[0 - 0 ] This buffer contains the alarm word for all alarms and

warnings that have occurred since the last reset or

power-up. The maximum buffer capacity is eight

error events.

9-47 Fault Number

Range: Function:

0

*

[0 - 0 ] This buffer contains the alarm number (e.g., 2 for live

zero error, 4 for line phase loss) for all alarms and

warnings that have occurred since last reset or

power-up. The maximum buffer capacity is eight

error events.

9-52 Fault Situation Counter

Range: Function:

0

*

[0 - 1000 ] This parameter displays the number of error

events which have occurred since the last reset of

power-up.

9-53 Profibus Warning Word

Range: Function:

0 N/A

*

[0 - 65535 N/A] This parameter displays Profibus

communication warnings. Please refer

to the Profibus Instruction Manual for

further information.

Read only

Bit: Meaning:

0 Connection with DP master is not ok

1 Not used

2 FDLNDL (Serial Communication Bus Data link Layer) is

not ok

3 Clear data command received

4 Actual value is not updated

5 Baudrate search

6 PROFIBUS ASIC is not transmitting

7 Initialization of PROFIBUS is not ok

8 The adjustable frequency drive is tripped.

9 Internal CAN error

10 Wrong configuration data from PLC

11 Wrong ID sent by PLC

12 Internal error occured

13 Not configured

14 Timeout active

15 Warning 34 active

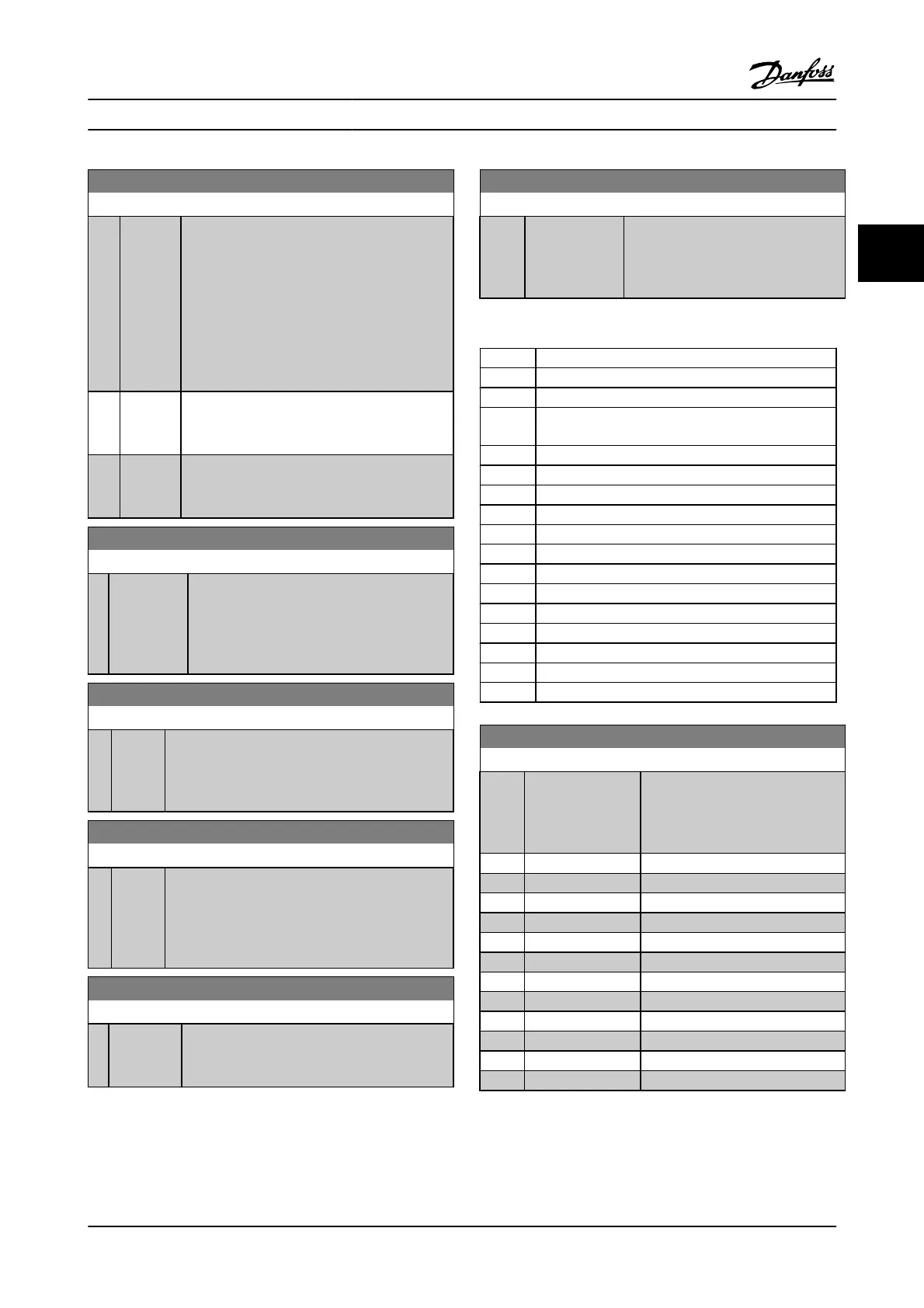

9-63 Actual Baud Rate

Option: Function:

This parameter displays the actual

Profibus baud rate. The Profibus

Master automatically sets the baud

rate.

[0] 9.6 kbit/s

[1] 19.2 kbit/s

[2] 93.75 kbit/s

[3] 187.5 kbit/s

[4] 500 kbit/s

[6] 1500 kbit/s

[7] 3000 kbit/s

[8] 6000 kbit/s

[9] 12000 kbit/s

[10] 31.25 kbit/s

[11] 45.45 kbit/s

[255]

*

No baud rate found

Parameter Descriptions FC 300 Programming Guide

MG.33.MA.22 - VLT

®

is a registered Danfoss trademark 3-95

3

Loading...

Loading...