4.2 Parameter Group 1: Load/Motor

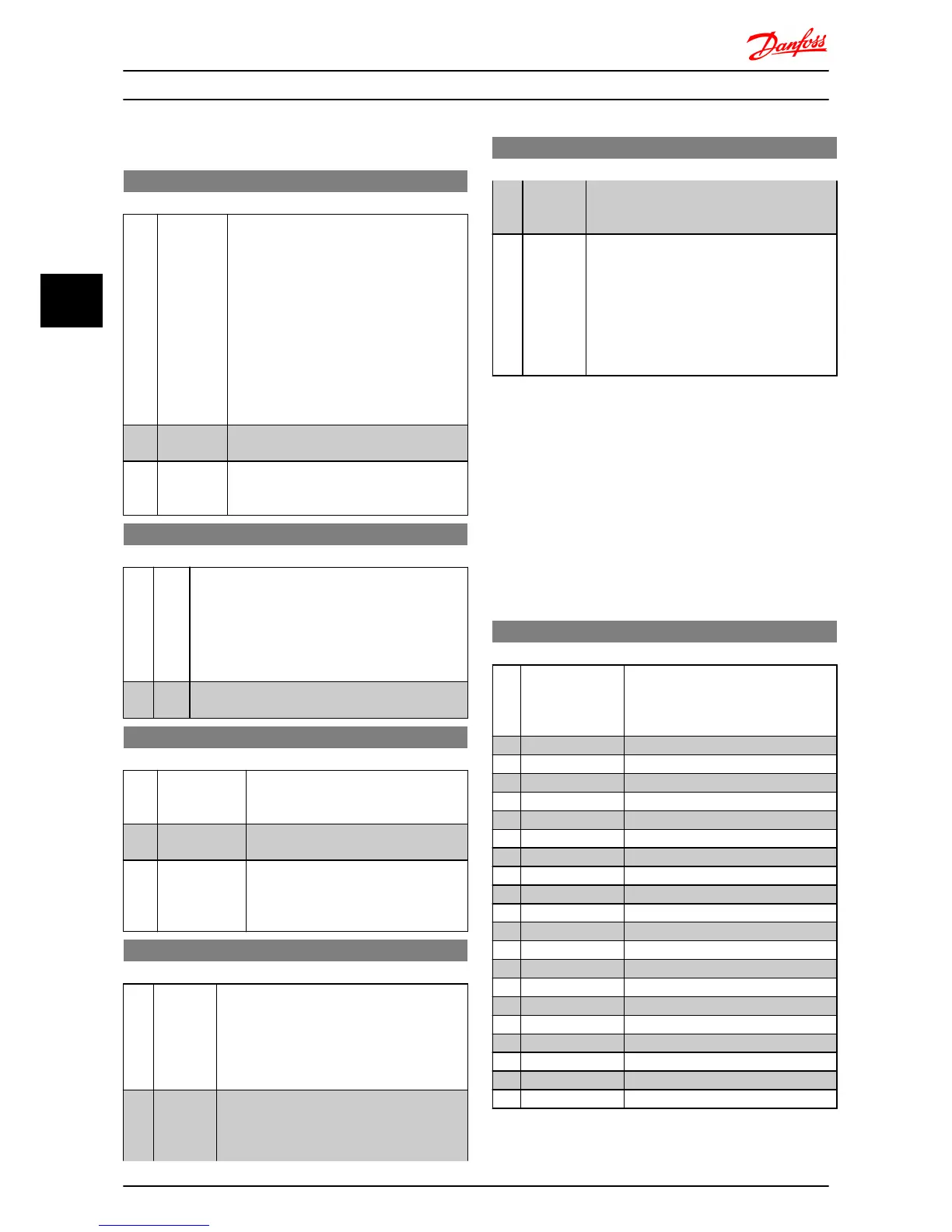

1-00 Configuration Mode

Option: Function:

Use this parameter for selecting the

application control principle to be used when

a Remote Reference is active.

NOTE

Changing this parameter will reset 3-00

Reference Range, 3-02 Minimum Reference

and 3-03 Maximum Reference to their

default values.

NOTE

This parameter cannot be adjusted

while motor runs.

[0 ] * Speed

Open Loop

For normal speed control (References).

[3] Process

Closed

Loop

Enables process closed loop control. See

parameter group 7-3* Process PI Control for

further information on PI-controller.

1-01 Motor Control Principle

Option: Function:

[0] U/f Is used for parallel connected motors and/or special

motor applications. The U/f settings are set in 1-55

U/f Characteristic -U and 1-56 U/f Characteristic -F.

NOTE

When running U/f control slip- and load

compensations are not included.

[1] * VVC+ Normal running mode, including slip- and load

compensations.

1-03 Torque Characteristics

Option: Function:

With more torque characteristics it is

possible to run low energy consuming, as

well as high torque applications.

[0 ] * Constant

Torque

Motor shaft output provides constant

torque under variable speed control.

[2] Automatic

Energy Optimi-

sation

This function automatically optimizes

energy consumption in centrifugal pump

and fan applications. See 14-41 AEO

Minimum Magnetisation.

1-05 Hand Mode Configuration

Option: Function:

This parameter is only relevant when 1-00

Configuration Mode is set to [3] Process Closed

Loop. The parameter is used for determining

the reference or setpoint handling when

changing from Auto Mode to Hand Mode on

the LCP.

[0] Speed

Open

Loop

In Hand Mode the drive always runs in Open

Loop configuration regardless of setting in 1-00

Configuration Mode. Local potentiometer (if

present) or Arrow up/down determines output

1-05 Hand Mode Configuration

Option: Function:

frequency limited by Motor Speed High/Low

Limit (4-14 Motor Speed High Limit and 4-12

Motor Speed Low Limit).

[2] * As config-

uration in

1-00

Configu-

ration

Mode.

If 1-00 Configuration Mode is set to [1] Open

Loop function is as described above.

If 1-00 Configuration Mode is set to [3] Process

Closed Loop changing from Auto mode to Hand

mode results in a setpoint change via local

potentiometer or Arrow up/down. The change

is limited by Reference Max/Min (3-02 Minimum

Reference and 3-03 Maximum Reference).

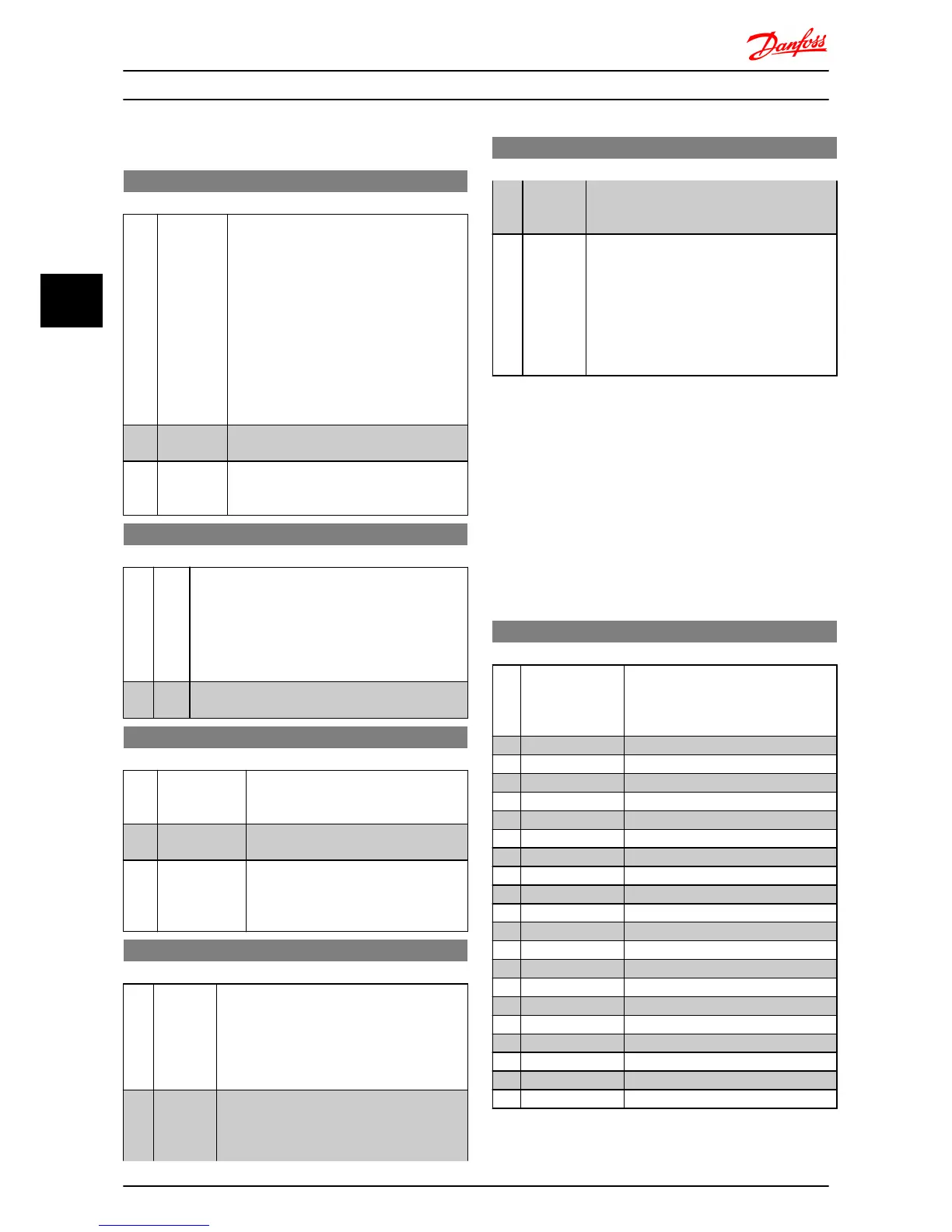

4.2.1 1-2* Motor Data

Enter the correct motor nameplate data (power, voltage,

frequency, current and speed).

Run AMT, see 1-29 Automatic Motor Tuning (AMT).

Factory settings for advanced motor data, parameter group

1-3* Adv. Motor Data, are automatically calculated.

NOTE

Parameters in parameter group 1-2* Motor Data cannot be

adjusted while motor runs.

1-20 Motor Power [kW]/[HP] (P

m.n

)

Option: Function:

Enter motor power from nameplate

data.

Two sizes down, one size up from

nominal VLT rating.

[1] 0.09 kW/0.12 HP

[2] 0.12 kW/0.16 HP

[3] 0.18kW/0.25 HP

[4] 0.25 kW/0.33 HP

[5] 0.37kW/0.50 HP

[6] 0.55 kW/0.75 HP

[7] 0.75 kW/1.00 HP

[8] 1.10 kW/1.50 HP

[9] 1.50 kW/2.00 HP

[10] 2.20 kW/3.00 HP

[11] 3.00 kW/4.00 HP

[12] 3.70 kW/5.00 HP

[13] 4.00 kW/5.40 HP

[14] 5.50 kW/7.50 HP

[15] 7.50 kW/10.0 HP

[16] 11.00 kW/15.00 HP

[17] 15.00 kW/20.00 HP

[18] 18.50 kW/25.00 HP

[19] 22.00 kW/29.50 HP

[20] 30.00 kW/40.00 HP

Parameter Descriptions

VLT

®

Micro Drive FC 51 Programming Guide

14 MG02C602 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...