VLT® 7000 Booster

Installation

■ Tightening-up torque and screw sizes

The table shows the torque required when

fitting terminals to the frequency converter. For

VLT 7002-7072, 380-460 V the cables must

be fastened with screws.

These figures apply to the following terminals:

91, 92, 93

Mains terminals (Nos.) L1, L2, L3

96, 97, 98

Motor terminals (Nos.) U, V, W

Earth terminal (Nos.) 94, 95, 99

VLT type

3 x 380-460 V

Tightening-up

torque

Screw/bolt

size

Allen

key

size

VLT 7002-7011 0.5-0.6 Nm M3

VLT 7016-7027 1.8 Nm (IP 20) M4

VLT 7032-7052 3.0 Nm (IP 20) M5

3)

4mm

VLT 7062-7072 6.0 Nm M6

3)

5mm

1. Loadsharing terminals 14 Nm/M6, 5 mm Allen key

3. Allen screws (hexagon)

4. Loadsharing terminals 9.5 Nm/M8 (bolt)

■ Mains connection

Mains must be connected to terminals

91, 92, 93 Mains voltage 3 x 380-460 V

NB!:

Check that the mains voltage fits the mains

voltage of the frequency converter, which

can be seen from the nameplate.

See Technical data for correct sizing of cable

cross-sections.

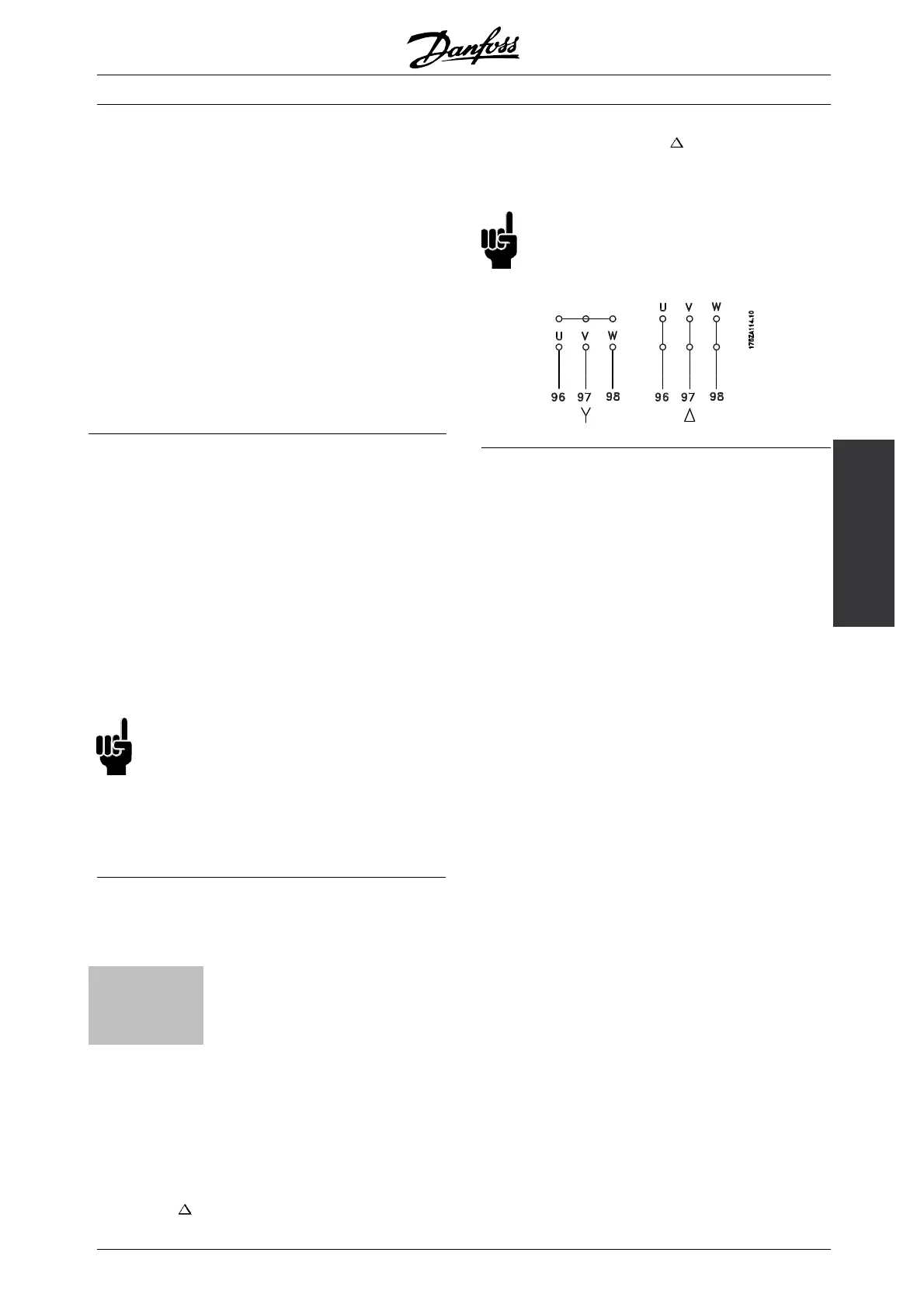

■ Motor connection

The motor must be connected to terminals 96,

97, 98. Earth to terminal 94/95/99.

Nos.

96. 97. 98

U, V, W

Motor voltage 0-100 % of mains voltage

No. 94/95/99 Earth connection

See Technical data for correct sizing of cable

cross-sections.

All types of three-phase asynchronous standard motors

can be used with a VLT 7000 Booster unit.

Small-size motors are normally star-connected.

(220/380 V,

/Y). Large-size motors are

delta-connected (380/660 V,

/Y). The correct

connection and voltage can be read from

the motor nameplate.

NB!:

In older motors without phase coil insulation,

a LC filter should be fitted to the frequency

converter output.

MG.70.A1.02 - VLT is a registered Danfoss trademark

35

Loading...

Loading...