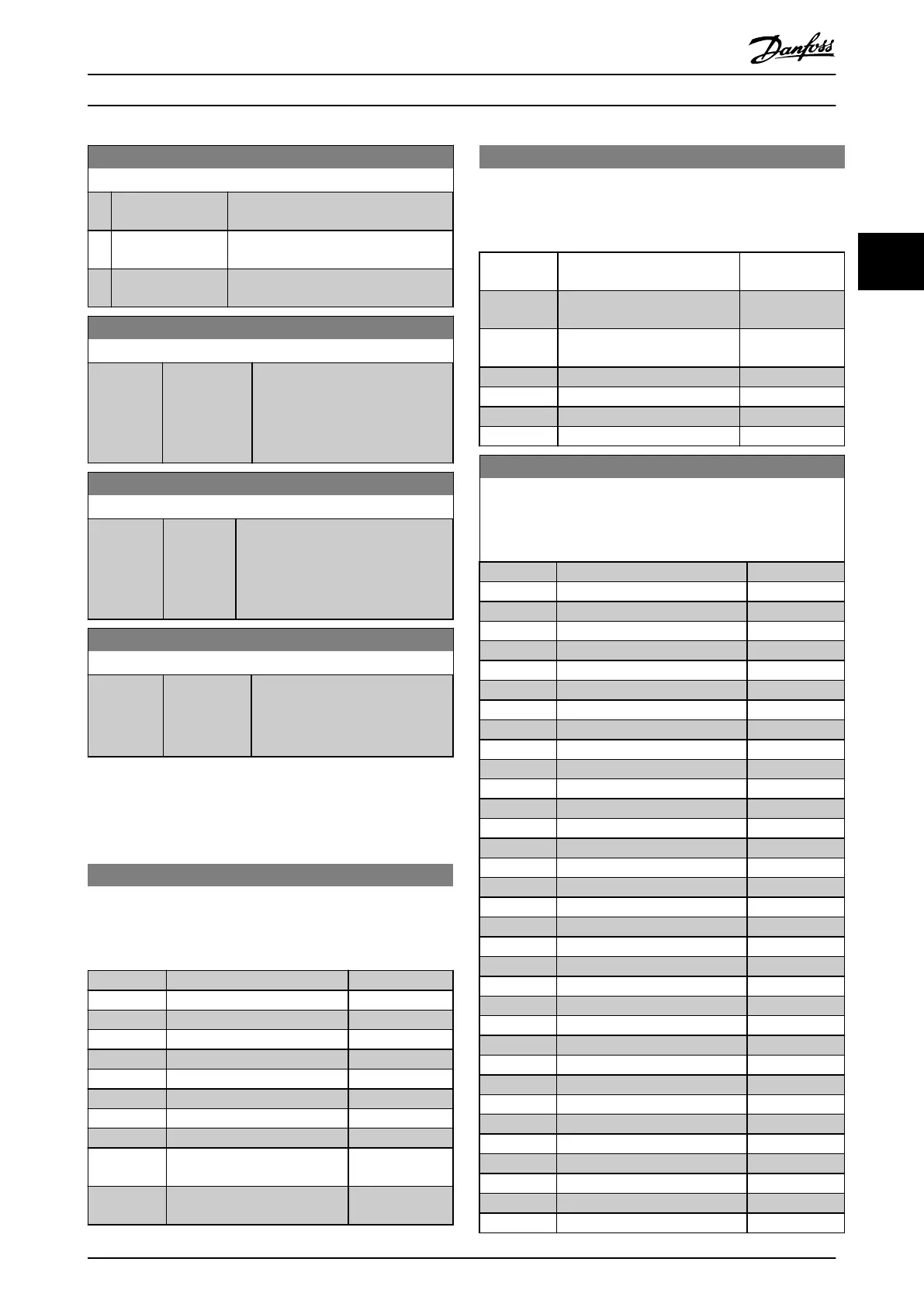

8-33 Parity / Stop Bits

Option: Function:

[1] Odd Parity, 1 Stop

Bit

[2] No Parity, 1 Stop

Bit

[3] No Parity, 2 Stop

Bits

8-35 Minimum Response Delay

Range: Function:

Size

related*

[ 0.0010 - 0.5

s]

Specify the minimum delay time

between receiving a request and

transmitting a response. This is

used for overcoming modem

turnaround delays.

8-36 Maximum Response Delay

Range: Function:

Size

related*

[ 0.1 -

10.0 s]

Specify the maximum permissible

delay time between receiving a

request and transmitting the response.

If this time is exceeded, no response is

returned.

8-37 Maximum Inter-char delay

Range: Function:

Size related* [ 0.005 -

0.025 s]

Specify the maximum delay time

between 2 characters in a message.

Exceeding this delay time causes

the message to be discarded.

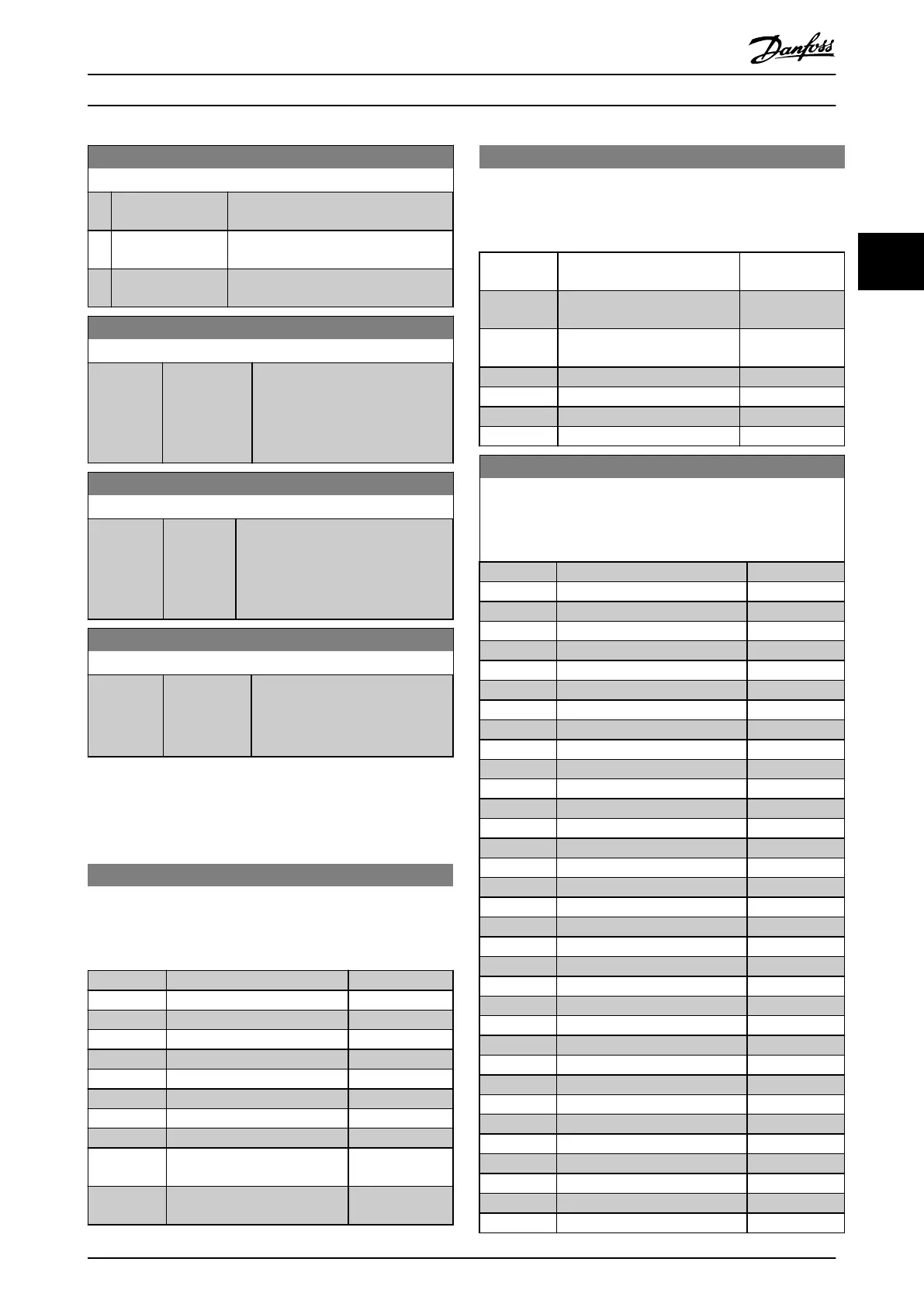

3.8.3 8-4* FC MC Protocol Set

This parameter group is for PCD write and read congu-

rations.

8-42 PCD Write Conguration

Dierent parameters can be assigned to PCD 3–10 of the PPOs

(the number of PCDs depends on the PPO type). The values in

PCD 3–10 are written to the selected parameters as data values.

Option: Function:

[0] None

[1] [302] Minimum Reference

[2] [303] Maximum Reference

[3] [341] Ramp 1 Ramp up time

[4] [342] Ramp 1 Ramp down time

[5] [351] Ramp 2 Ramp up time

[6] [352] Ramp 2 Ramp down time

[7] [380] Jog Ramp Time

[8] [381] Quick Stop Time

[9] [412] Motor Speed Low Limit

[Hz]

[10] [414] Motor Speed High Limit

[Hz]

8-42 PCD Write Conguration

Dierent parameters can be assigned to PCD 3–10 of the PPOs

(the number of PCDs depends on the PPO type). The values in

PCD 3–10 are written to the selected parameters as data values.

Option: Function:

[11] [590] Digital & Relay Bus

Control

[12] [676] Terminal45 Output Bus

Control

[13] [696] Terminal 42 Output Bus

Control

[14] [894] Bus Feedback 1

[15] FC Port CTW

[16] FC Port REF

[17] [2021] Setpoint 1

8-43 PCD Read Conguration

Dierent parameters can be assigned to PCD 3–10 of the PPOs

(the number of PCDs depends on the PPO type). PCD 3–10 hold

the actual data value of the selected parameters.

Option: Function:

[0] None

[1] [1500] Operation Hours

[2] [1501] Running Hours

[3] [1502] kWh Counter

[4] [1600] Control Word

[5] [1601] Reference [Unit]

[6] [1602] Reference %

[7] [1603] Status Word

[8] [1605] Main Actual Value [%]

[9] [1609] Custom Readout

[10] [1610] Power [kW]

[11] [1611] Power [hp]

[12] [1612] Motor Voltage

[13] [1613] Frequency

[14] [1614] Motor Current

[15] [1615] Frequency [%]

[16] [1618] Motor Thermal

[17] [1630] DC Link Voltage

[18] [1634] Heatsink Temp.

[19] [1635] Inverter Thermal

[20] [1638] SL Controller State

[21] [1650] External Reference

[22] [1652] Feedback [Unit]

[23] [1660] Digital Input 18,19,27,33

[24] [1661] Terminal 53 Switch Setting

[25] [1662] Analog input 53

[26] [1663] Terminal 54 Switch Setting

[27] [1664] Analog input 54

[28] [1665] Analog output 42 [mA]

[29] [1671] Relay output

[30] [1672] Counter A

[31] [1673] Counter B

[32] [1690] Alarm Word

[33] [1692] Warning Word

Parameters Programming Guide

MG18B502 Danfoss A/S © 04/2018 All rights reserved. 63

3 3

Loading...

Loading...