Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

• The tubes in the peristaltic pumps should

be replaced at least two times a year.

• The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

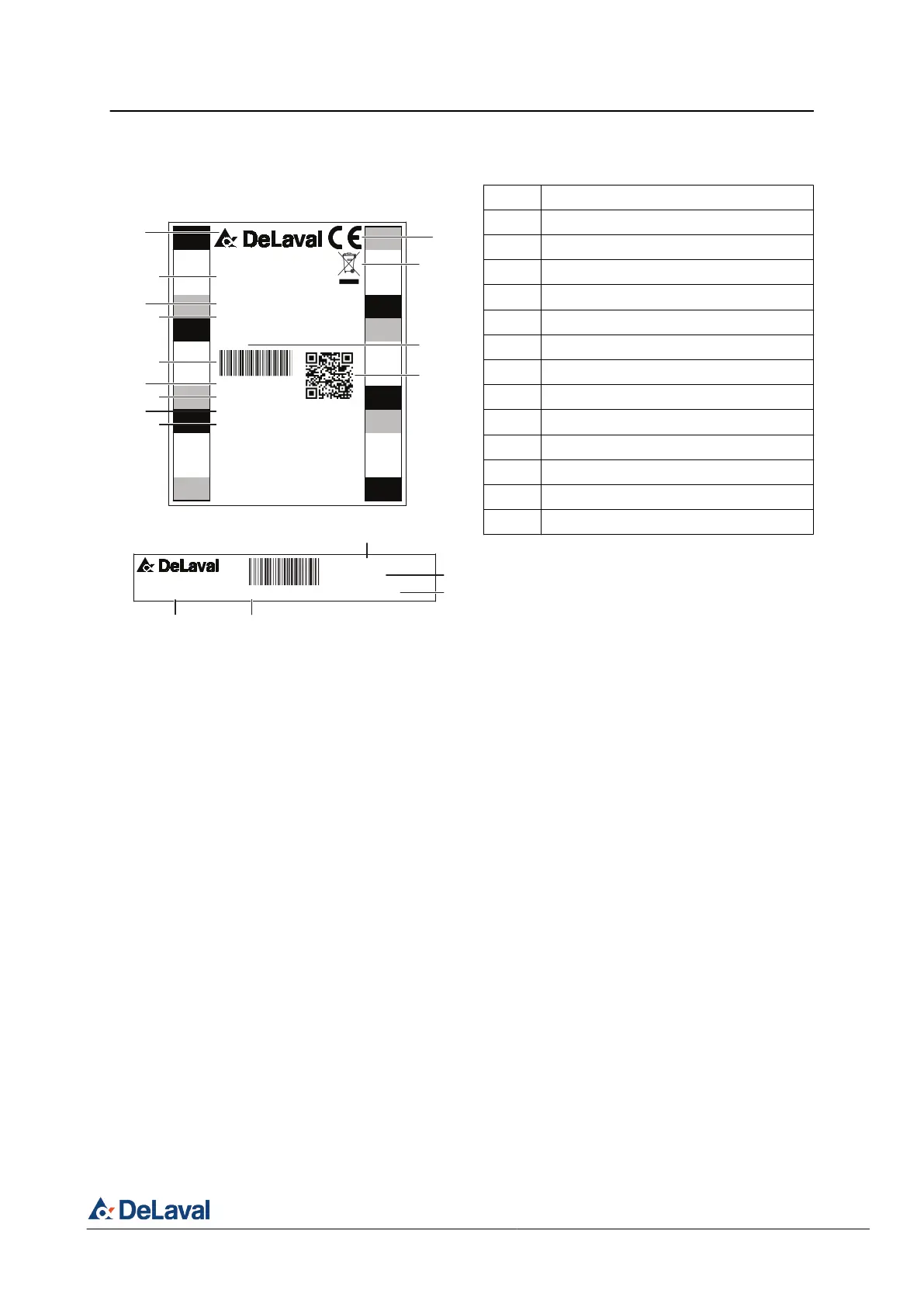

A DeLaval logotype

B CE-marking

C DeLaval address

D Crossed household waste bin

E Country of origin

F Module type

G Module model

H Bar code

J QR-code

K Article number

L Serial number

M Bluetooth address

N Supply voltage

P DeLaval web page address

9 Warranty

Note! DeLaval will not take any responsibility for

damage resulting from faulty installation, opera-

tion, or for improper or inadequate care and

maintenance.

Note! DeLaval will not take any responsibility for

any damage resulting from frost. The owner/user

must take the necessary measurements to pre-

vent the ambient temperature around the equip-

ment from dropping to or below freezing point.

Note! Modification may create risks not covered

by the original construction. Do not make any

modifications which has not been approved by

DeLaval.

DeLaval International AB

P.O. Box 39

SE-147 21 Tumba, Sweden

Made in Sweden

Type:

Model:

Art No:

Serial no :

ID:

Supply voltage:

11

14

15

18

19

22

23

7

6

3

2

5

4

1

8

9

10

13

16

17

20

21

24

12

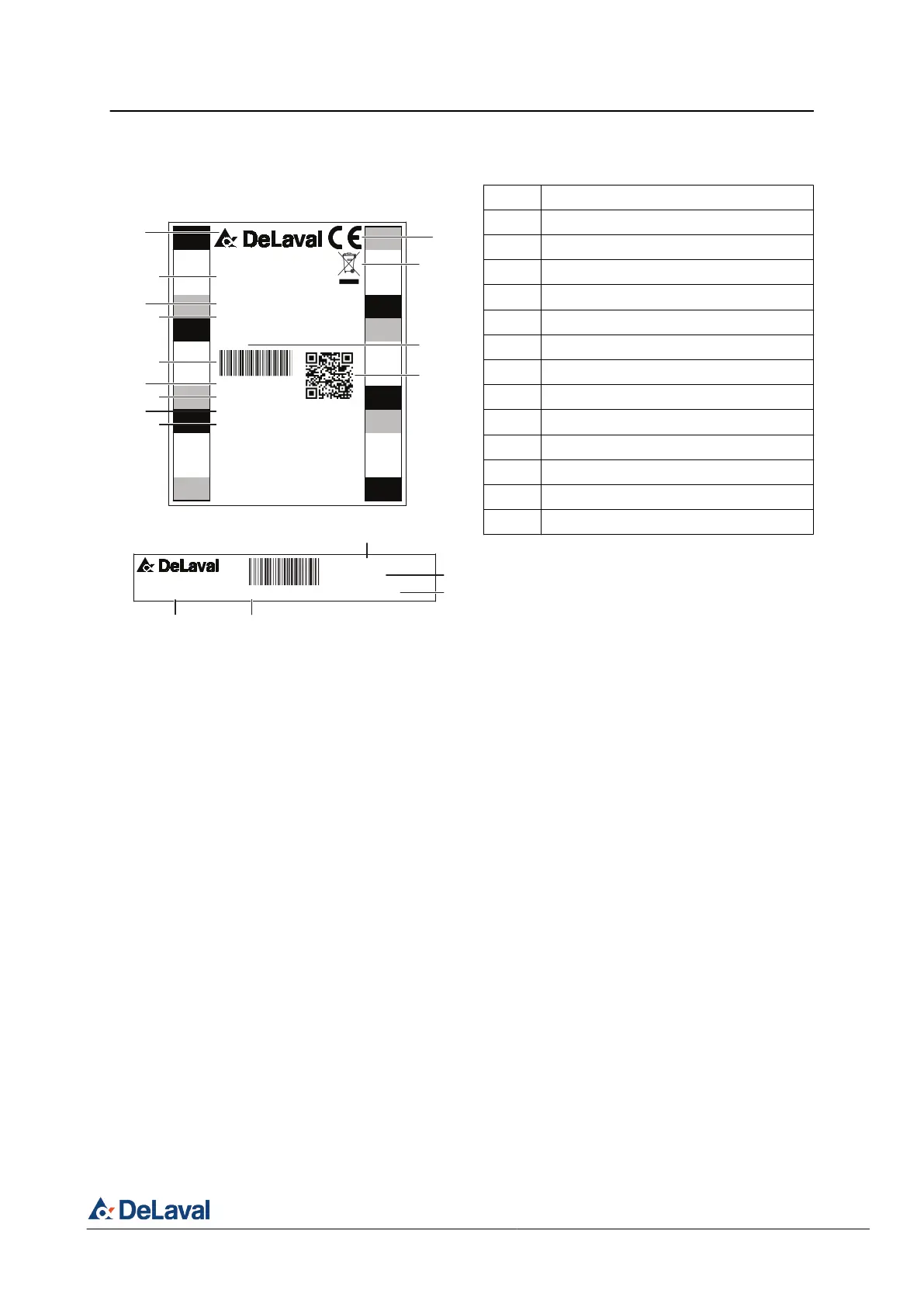

Model:

Art No:

ID:

www.delaval.com

Serial No:

A

B

D

J

G

G

MP

K

L

C

H

E

F

K

L

M

N

275619

Fig. 3: Module type plate.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 11 (62)

Loading...

Loading...