Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

• The tubes in the peristaltic pumps should

be replaced at least two times a year.

• The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

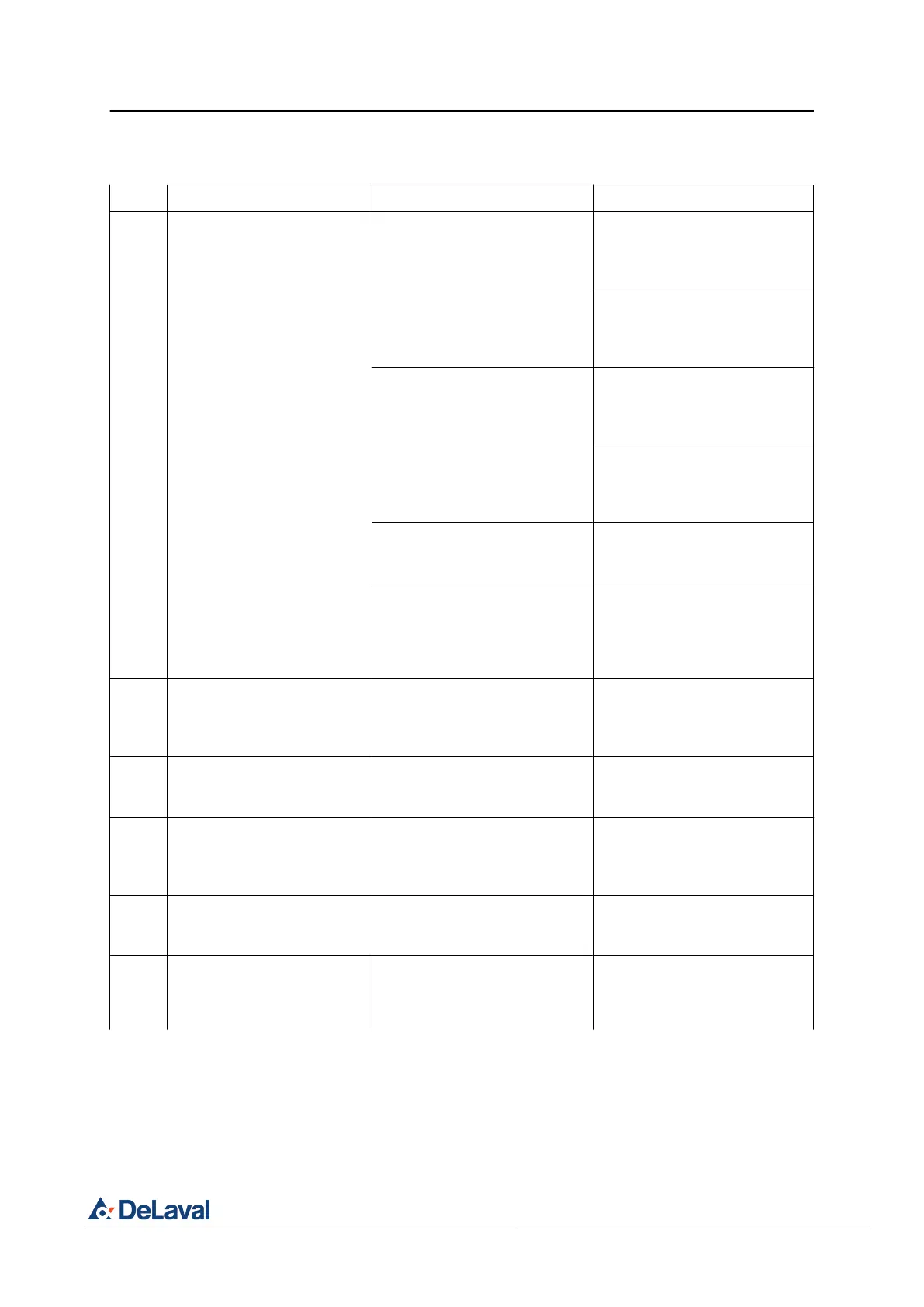

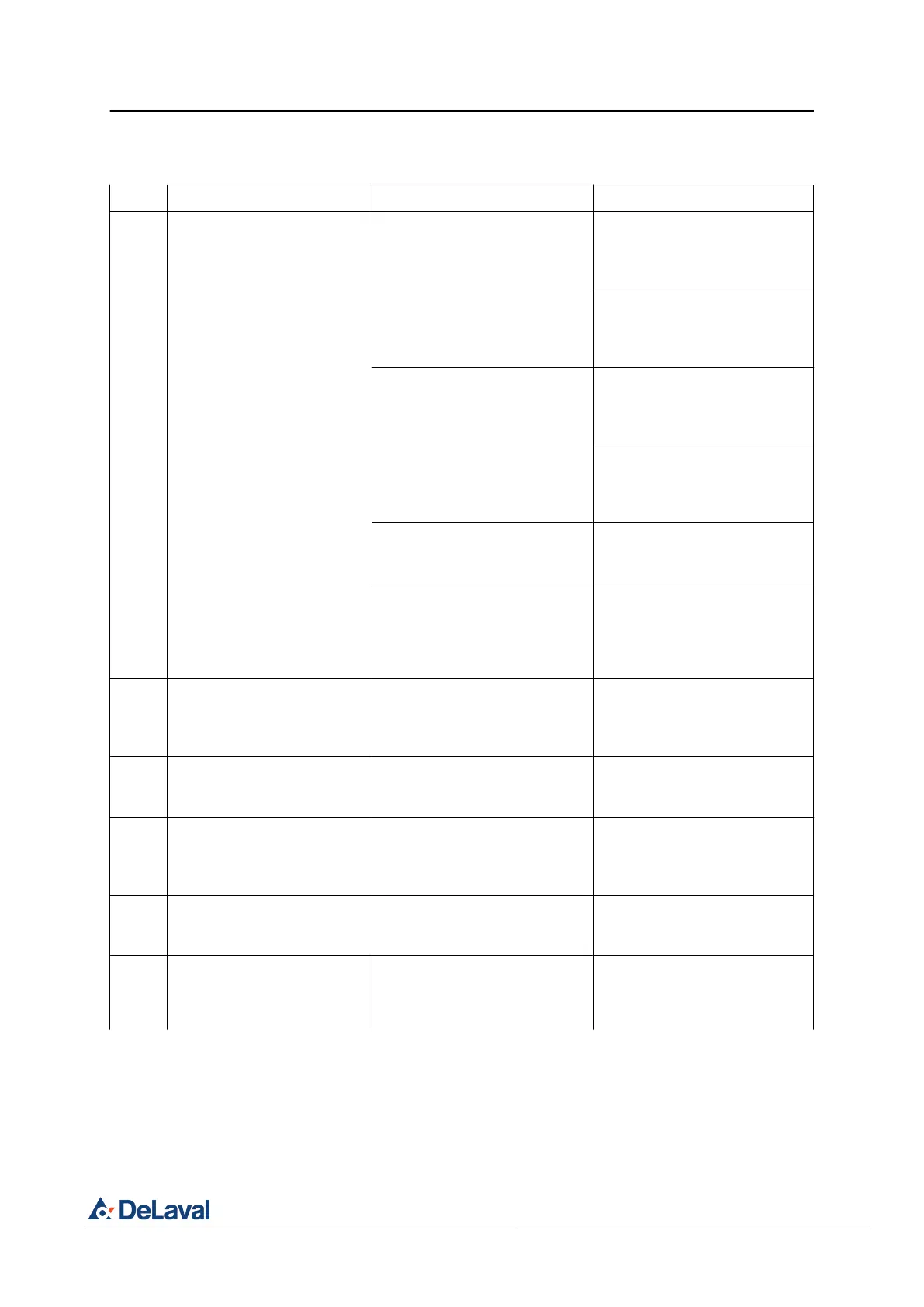

No. Symptom Cause Action

1 The fuses or thermal protec-

tion are broken repeatedly in

the power supply.

The cable type used between

the power supply to the com-

munication and control module

is incorrect.

Contact an authorised service

technician.

The cable type between the

communication and control

module and the input/output

module is incorrect

Contact an authorised service

technician.

The wiring between the power

supply and the communication

and control module and input/

output module is incorrect.

Contact an authorised service

technician.

The wiring between the com-

munication and control module

and the input/output module is

incorrect

Contact an authorised service

technician.

The wiring between the button

module and the interface box /

smart control box is incorrect.

Contact an authorised service

technician.

The installer did not follow the

power consumption guidelines

and connected too many input/

output modules or/and button

modules to one 5 A circuit.

Contact an authorised service

technician.

2 The clusters are removed

too early during milking in

one or several milking points.

There is a communication

problem between the input/out-

put module and the milk meter /

flow sensor.

Contact an authorised service

technician.

3 The clusters are removed

too late during milking in one

or several milking points.

Incorrectly programmed

parameters.

Contact an authorised service

technician.

4 The clusters are retracted

during cleaning in one or

several milking points in

cleaning mode.

There is a problem with timing

of the milking / cleaning signals.

Contact an authorised service

technician.

5 Communication interruption

with flow sensor in external

rotary.

A DeLaval teat spray robot TSR

is installed which might disturb

the button module.

Contact an authorised service

technician.

6 The button module behaves

erratic.

The button module is exposed

to high temperatures or signifi-

cant temperature difference

repetitively.

Contact an authorised service

technician.

» Continue next page

DeLaval milking automation MA200 (Test installation)

Troubleshooting

© DeLaval 2019.

2019-05-31, Version 1 59 (62)

Loading...

Loading...