Chapter 6 Control Mode of Operation ASDA-A2

6-24 Revision February, 2017

6.3 Speed Mode

Speed control mode (S or Sz) is applicable in precision speed control, such as CNC machine tools.

This servo drive includes two types of command input, analog and register. Analog command input

can use external voltage to control the motor speed. There are two methods in register input. One

is used before operation. Users set different value of speed command in three registers, and then

use SP0, SP1 of CN1 DI signal for switching. Another method is to change the value of register by

communication. In order to deal with the problem of non-continuous speed command when

switching register, a complete S-curve program is provided. In close-loop system, this servo drive

adopts gain adjustment and integrated PI controller and two modes (manual and auto) for selection.

Users can set all parameters and all auto or auxiliary function will be disabled in manual mode.

While in auto mode, it provides the function of load inertia estimation and parameter adjustment. In

auto mode, parameters which set by users will be regarded as the default value.

6.3.1 Selection of Speed Mode

There are two types of speed command source, analog voltage and internal parameters. The

selection is determined by CN1 DI signal. See as the followings.

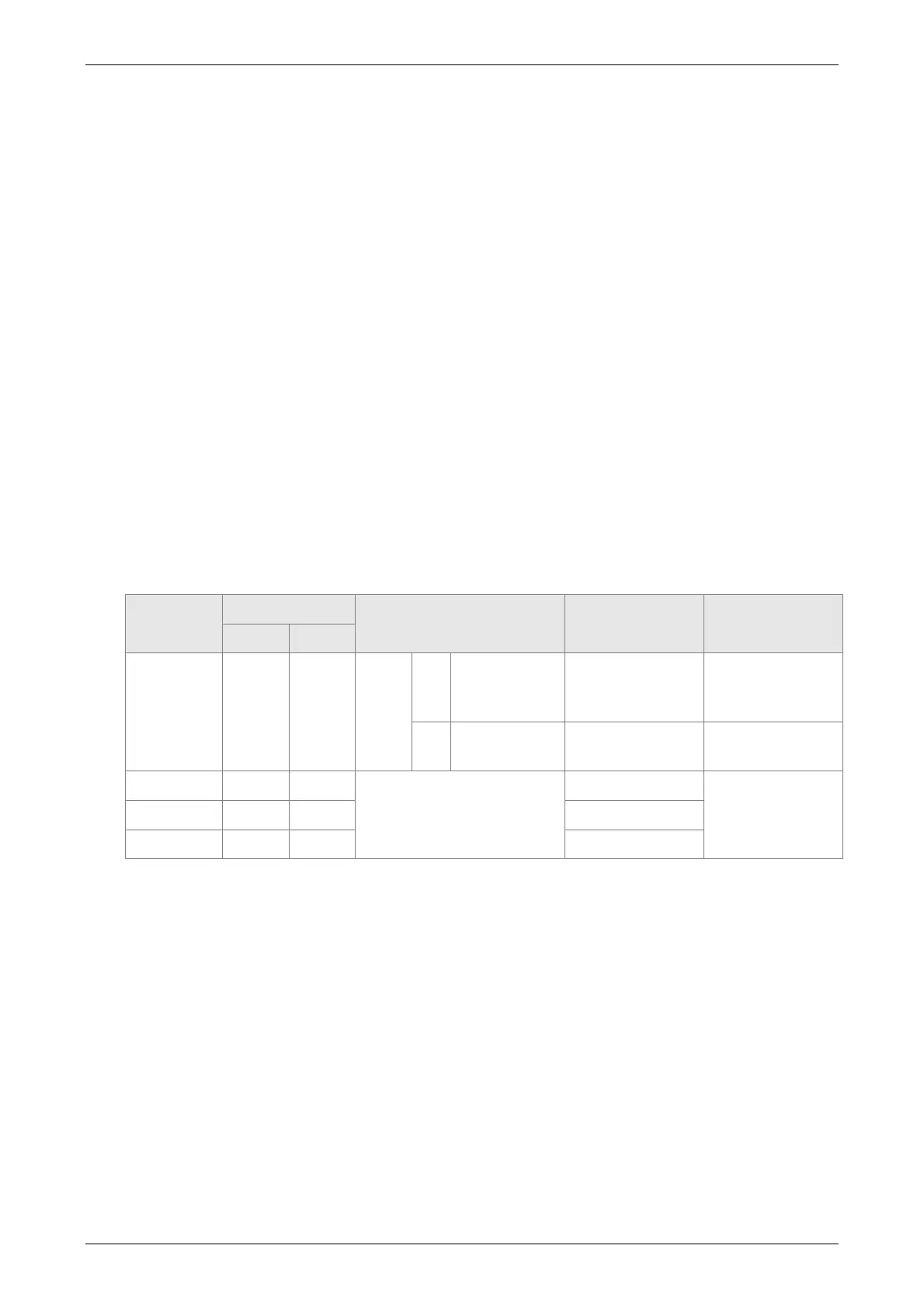

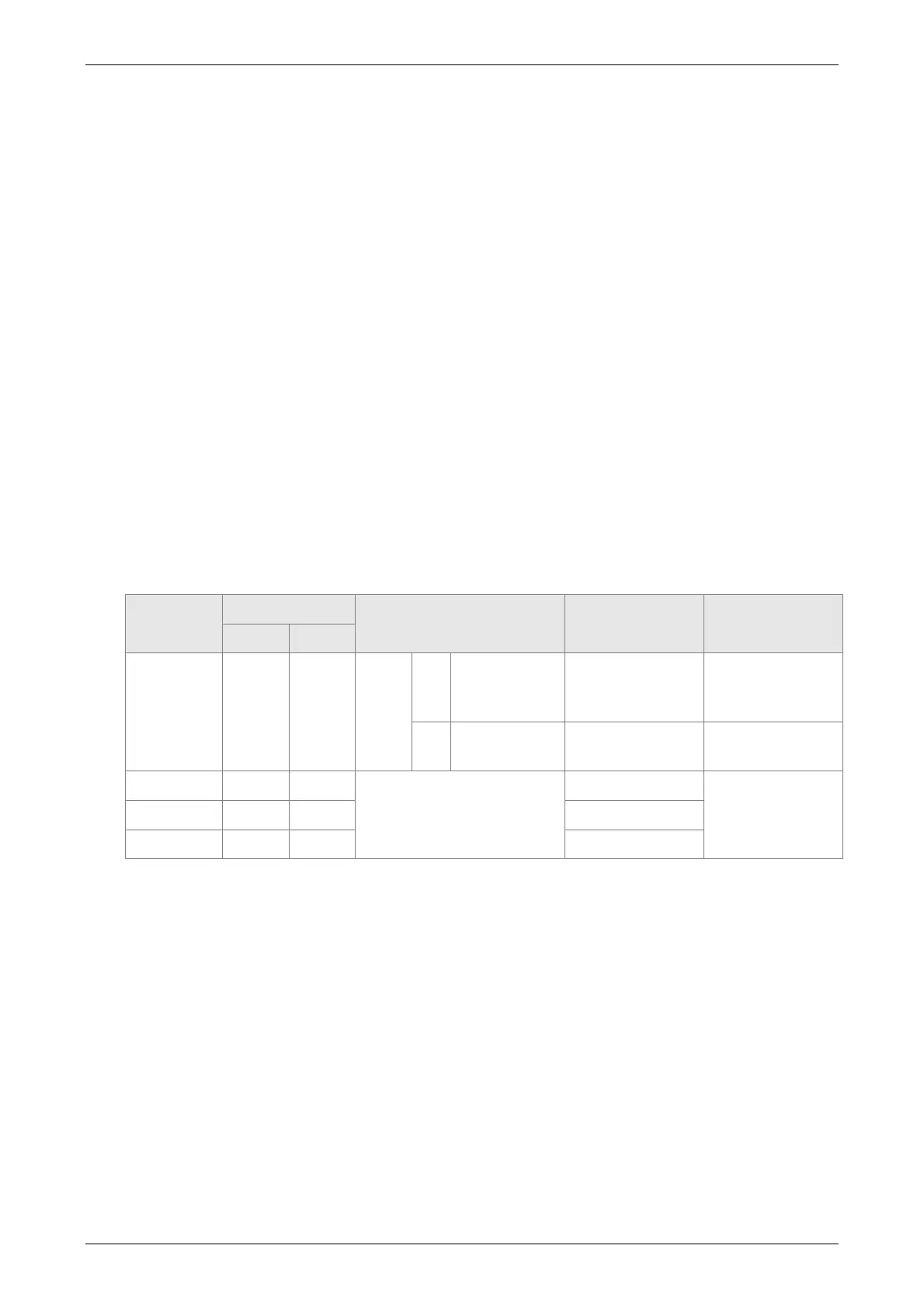

Speed

Command

CN1 DI signal

Command Source Content Range

SPD1 SPD0

S1 0 0 Mode

S

External

analog

signal

Voltage

between V-

REF-GND

-10 V ~ +10V

Sz N/A

Speed

command is 0

0

S2 0 1

Register parameters

P1-09

-60000 ~ 60000

S3 1 0 P1-10

S4 1 1 P1-11

Status of SPD0 ~ SPD1: 0 means DI OFF, 1 means DI ON.

When both SPD0 and SPD1 are 0, if it is in Sz mode, the command will be 0. Thus, if there

is no need to use analog voltage as the speed command, Sz mode can be applied to tackle

the problem of zero-drift. If it is in S mode, the command will be the voltage deviation

between V-REF and GND. The range of input voltage is between -10V and +10V and its

corresponding speed is adjustable (P1-40).

When one of SPD0 and SPD1 is not 0, the speed command is from the internal parameter.

The command is activated after changing the status of SPD0~SPD1. There is no need to

use CTRG for triggering.

Loading...

Loading...