ASDA-A2 Chapter 10 Troubleshooting

10-28 Revision February, 2017

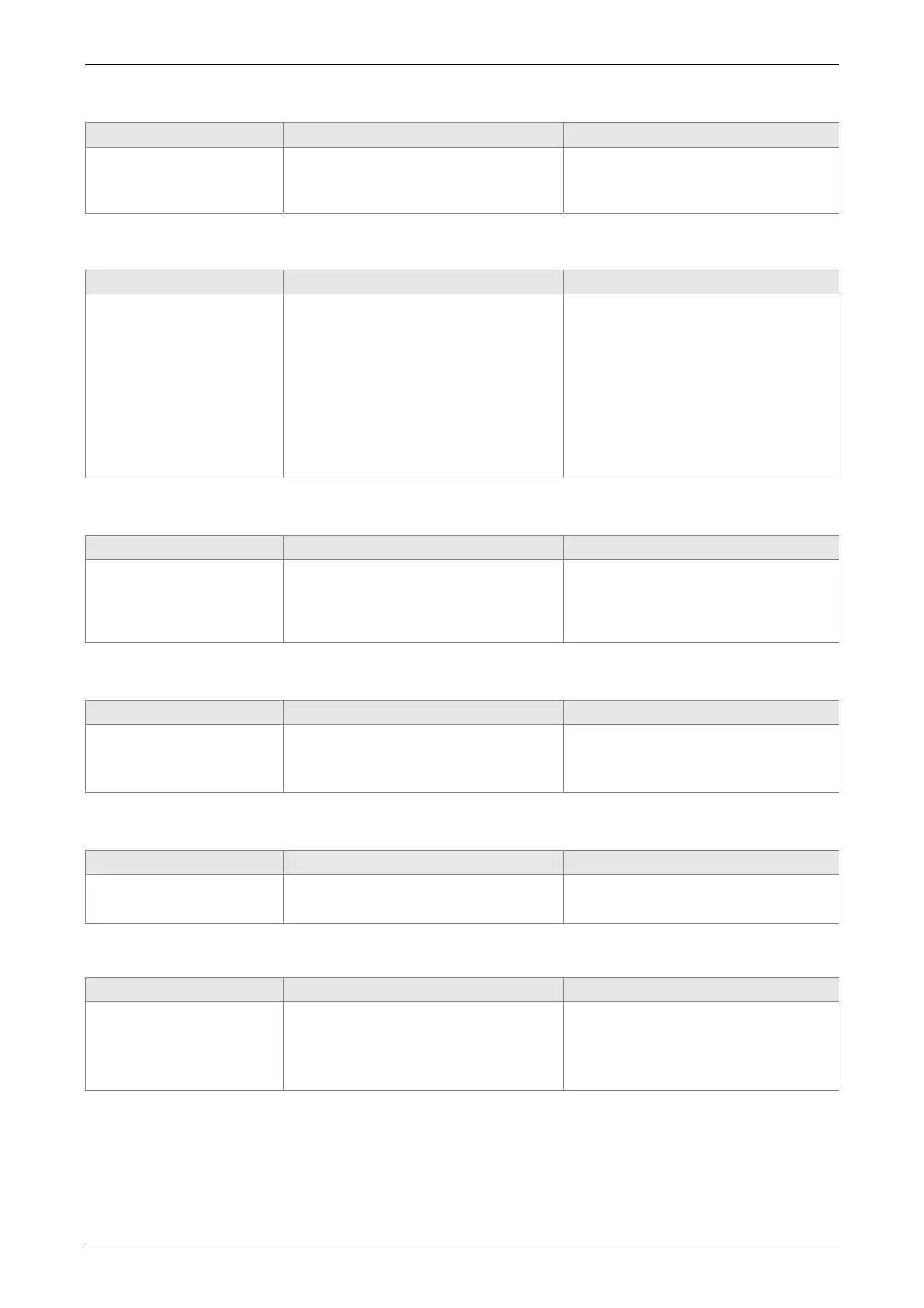

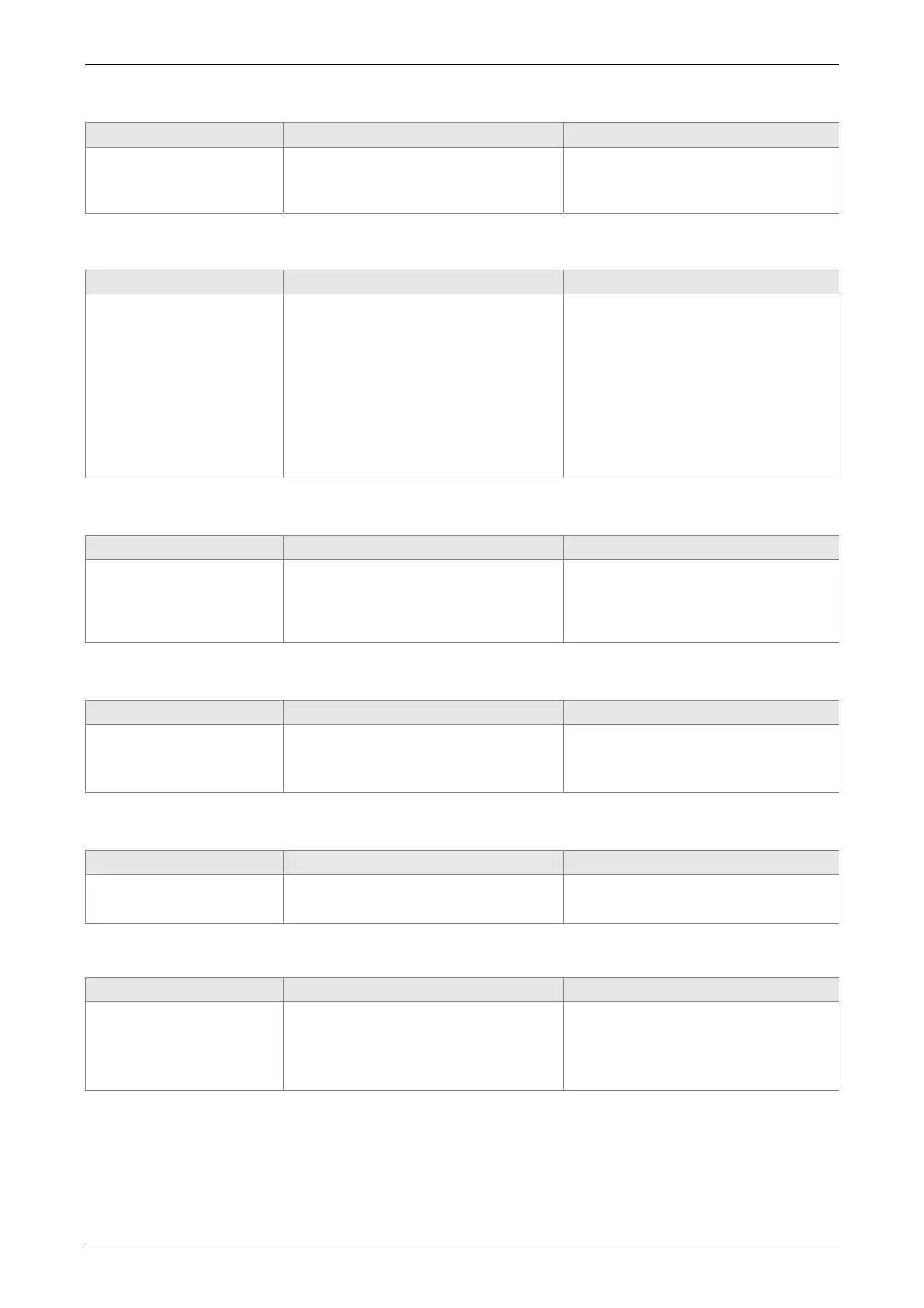

AL305:SYNC Period is in error

Causes Checking Method Corrective Actions

SYNC Period is in error

Examine the content of 0x1006.If

it is smaller than or equals to 0, the

alarm will occur.

NMT: Reset node or 0x6040.Fault

Reset

AL380:Position Deviation Alarm

Causes Checking Method Corrective Actions

DO.MC_OK is ON and

becomes OFF.

Please refer to the description of

parameter P1-48.

After DO.MC_OK ON, DO.MC_OK

becomes OFF because DO.TPOS

turns OFF.

The position of the motor might be

deviated by the external force after

positioning. This alarm can be

cleared by P1-48.Y=0.

DI.Alm Reset or P0-01= 0

AL400: Index coordinates error

Causes Checking Method Corrective Actions

Setting of P2-52 is wrong

Check if the setting of P2-52 is

within the range. If the setting value

is too small, it would cause index

coordinates error.

Re-adjust the value of P5-52 until it

is appropriate.

AL401:Receives NMT reset command when Servo On

Causes Checking Method Corrective Actions

Receives NMT reset

command when Servo

On

Check if the servo drive receives

NMT reset command when Servo

On

NMT:Reset node or 0x6040.Fault

Reset

AL404:Value of PR special filter setting is too big

Causes Checking Method Corrective Actions

Inner position error

overflows

The setting value of P1-22 causes

inner position error overflows

Re-adjust the value of P1-22 until it

is appropriate.

AL555:System Failure

Causes Checking Method Corrective Actions

DSP processing error

N/A

If AL555 occurs, do not do any

anything and send the drive back to

the distributors or contact with

Delta.

Loading...

Loading...