ASDA-A2 Chapter 10 Troubleshooting

10-12 Revision February, 2017

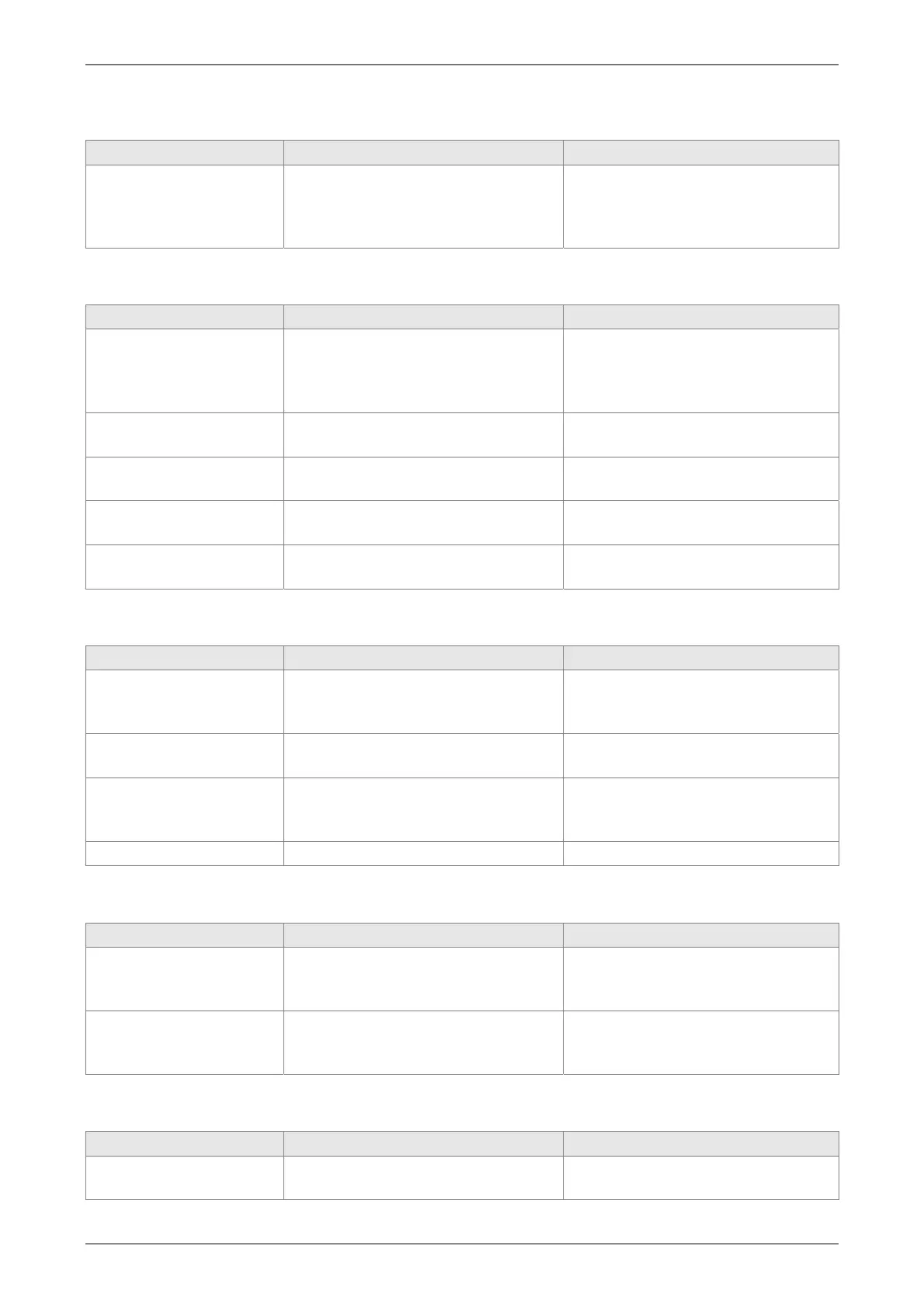

AL008:Abnormal Pulse Command

Causes Checking Method Corrective Actions

The pulse command

frequency is higher than

the rated input

frequency.

Use the scope to check if the input

frequency is over the rated input

frequency.

Correctly set the input pulse

frequency.

AL009:Excessive Deviation of Position Command

Causes Checking Method Corrective Actions

Parameter P2-35 is set

too small

Check the setting value of

parameter P2-35 (The warning

condition of excessive position

deviation)

Increase the setting value of P2-35

(The warning condition of

excessive position deviation)

The setting of the gain

value is too small.

Check if the setting value is

appropriate

Correctly adjust the gain value

The torque limit is too

low.

Check the torque limit value

Correctly adjust the torque limit

value

Excessive external load Check the external load

Reduce the external load or

evaluate the motor capacity again

Improper setting of E-

gear ratio

Make sure if the proportion of P1-44

and P1-45 is appropriate.

Correctly setup E-gear ratio

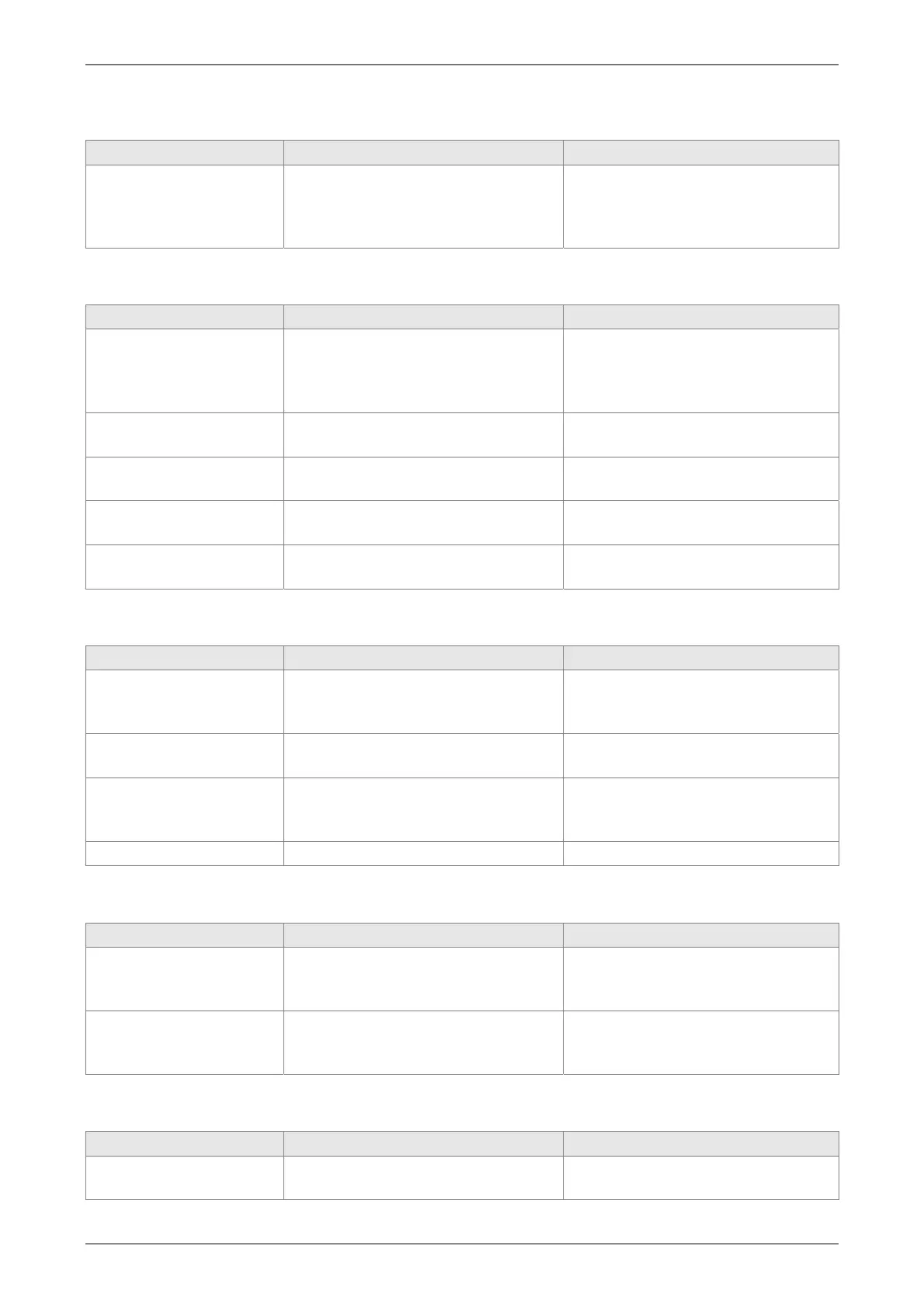

AL011:Encoder Error

Causes Checking Method Corrective Actions

Wrong wiring of the

encoder

Check if the wiring follows the

suggested wiring of the user

manual.

Correct wiring

The encoder is loose

Check the drive connector of CN2

and encoder

Install the encoder again

Bad connection of the

encoder

Check if the connection between

CN2 of the drive and the encoder of

the servo motor is loose

Reconnect the wiring

The encoder is damaged Check if the motor is damaged Change the motor

AL012:Adjustment Error

Causes Checking Method Corrective Actions

The analog input contact

is incorrectly set back to

zero

Measure if the voltage of the analog

input contact is the same as the

ground voltage

Correctly ground the analog input

contact

The detection device is

damaged

Reset the power supply

If the error still occurs after reset,

send the drive back to the

distributors or contact with Delta.

AL013:Emergency Stop

Causes Checking Method Corrective Actions

Press the emergency

stop button

Check if the emergency stop button

is enabled.

Activate emergency stop

Loading...

Loading...