http://www.delta.com.tw/industrialautomation/

High Performance‧Precise Position

Control‧High Resolution AC Servo

Drive for Communication Network

Applications

Instruction Sheet

X General Precautions

This instruction sheet will be helpful in the installation, wiring, inspection, and operation of Delta ASDA-A2 series AC servo drive

and ECMA series servo motor. Before using the product, please read this instruction sheet to ensure correct use. You should

thoroughly understand all safety precautions before proceeding with the installation, wiring and operation. If you do not

understand please contact your local Delta sales representative. Place this instruction sheet in a safe location for future reference.

Please observe the following precautions:

Do not use the product in a potentially explosive environment.

Install the product in a clean and dry location free from corrosive and inflammable gases or liquids.

Do not connect a commercial power supply to the U, V, W terminals of motor. Failure to observe this precaution will

damage either the Servo motor or drive.

Ensure that the motor and drive are correctly connected to a ground. The grounding method must comply with the

electrical standard of the country (Please refer to NFPA 70: National Electrical Code, 2005 Ed.).

Do not disconnect the AC servo drive and motor while the power is ON.

Do not attach, modify or remove wiring when power is applied to the AC servo drive and motor.

Before starting the operation with a mechanical system connected, make sure the emergency stop equipment can be

energized and work at any time.

Do not touch the drive heat sink or the servo motor during operation. Otherwise, it may result in serious personnel injury.

Further information on the AC servo drive and motor can be obtained from the manual. You can download the manual via the link

http://www.delta.com.tw/industrialautomation/

above in PDF format.

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/industrialautomation/

.

Y Safety Precautions

Carefully note and observe the following safety precautions when receiving, inspecting, installing, operating, maintaining and

troubleshooting. The following words, DANGER, WARNING and STOP are used to mark safety precautions when using the

Delta’s servo product. Failure to observe these precautions may void the warranty!

ASDA-A2 series drives are high-resolution, open type servo drives and must be installed in an NEMA enclosure such as a

protection control panel during operation to comply with the requirements of the international safety standards. They are provided

with precise feedback control and high-speed calculation function incorporating DSP (Digital Signal Processor) technology, and

intended to drive three-phase permanent magnet synchronous motors (PMSM) to achieve precise positioning by means of

accurate current output generated by IGBT (Insulated Gate Bipolar Transistor).

ASDA-A2 series drives can be used in industrial applications and for installation in an end-use enclosure that do not exceed the

specifications defined in the ASDA-A2 series user manual (Drives, cables and motors are for use in a suitable enclosure with a

minimum of a UL50 type 1 or NEMA 250 Type 1 rating).

Unpacking Check

¾ Please ensure that both the servo drive and motor are correctly matched for size (power rating). Failure to observe this

precaution may cause fire, seriously damage the drive / motor or cause personal injury.

Installation

¾ Do not install the product in a location that is outside the stated specification for the drive and motor. Failure to observe

this caution may result in electric shock, fire, or personal injury.

Wiring

¾ Connect the ground terminals to a class-3 ground (Ground resistance should not exceed 100Ω). Improper grounding may

result in electric shock or fire.

¾ Do not connect any power supplies to the U, V, W terminals. Failure to observe this precaution may result in serious

injury, damage to the drive or fire.

¾ Ensure that all screws, connectors and wire terminations are secure on the power supply, servo drive and motor. Failure

to observe this caution may result in damage, fire or personal injury.

¾ In order to prevent fire hazard and accidents, please form the wiring by following the cable specifications outlined in this

quick start.

Operation

¾ Before starting operation with a mechanical system connected, change the drive parameters to match the user-defined

parameters of the mechanical system. Starting the operation without matching the correct parameters may result in servo

drive or motor damage, or damage to the mechanical system.

¾ Ensure that the emergency stop equipment or device is connected and working correctly before operating the motor that is

connected to a mechanical system.

¾ Do not approach or touch any rotating parts (e.g. shaft) while the motor is running. Failure to observe this precaution

may cause serious personal injury.

¾ In order to prevent accidents, the initial trial run for servo motor should be conducted under no load conditions (separate

the motor from its couplings and belts).

¾ For the initial trial run, do not operate the servo motor while it is connected to its mechanical system. Connecting the

motor to its mechanical system may cause damage or result in personal injury during the trail run. Connect the servo

motor once it has successfully completed a trail run.

¾ Caution: Please perform trial run without load first and then perform trial run with load connected. After the servo motor

is running normally and regularly without load, then run servo motor with load connected. Ensure to perform trial run in

this order to prevent unnecessary danger.

¾ Do not touch either the drive heat sink or the motor during operation as they may become hot and personal injury may

result.

Maintenance and Inspection

¾ Do not touch any internal or exposed parts of servo drive and servo motor as electrical shock may result.

¾ Do not remove the operation panel while the drive is connected to an electrical power source otherwise electrical shock

may result.

¾ Wait at least 10 minutes after power has been removed before touching any drive or motor terminals or performing any

wiring and/or inspection as an electrical charge may still remain in the servo drive and servo motor with hazardous

voltages even after power has been removed.

¾ Do not disassemble the servo drive or motor as electric shock may result.

¾ Do not connect or disconnect wires or connectors while power is applied to the drive and motor.

¾ Only qualified personnel who have electrical knowledge should conduct maintenance and inspection.

¾ Ensure that the “Charge” indicator ceases when performing any maintenance, inspection or repairing.

Main Circuit Wiring

¾ Install the encoder cables in a separate conduit from the motor power cables to avoid signal noise. Separate the conduits

by 30cm (11.8inches) above.

¾ Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for signal, encoder (PG) feedback cables. The

maximum length of command input cable is 3m (9.84ft.) and the maximum length of encoder (PG) feedback cables is 20m

(65.62ft.).

¾ As a charge may still remain in the drive with hazardous voltages even after power has been removed, be sure to wait at

least 10 minutes after power has been removed before performing any wiring and/or inspection.

¾ It is not recommended to frequently power the drive on and off. Do not turn the drive off and on more than once per

minute as high charging currents within the internal capacitors may cause damage.

Main Circuit Terminal Wiring

¾ Please perform the wiring after the terminal blocks are all removed from the drive.

¾ Insert only one wire into one terminal on the terminal block.

¾ When inserting wires, please ensure that the conductors are not shorted to adjacent terminals or wires.

¾ Ensure to double check the wiring before applying power to the drive.

Z Servo Drive and Servo Motor Combinations

Power Servo Drive Servo Motor

200W ASD-A2-0221- ECMA-C10602S (S=14mm)

400W ASD-A2-0421-

ECMA-C10604S (S=14mm)

ECMA-C108047 (7=14mm)

ECMA-E11305S (S=22mm)

ECMA-G11303S (S=22mm)

750W ASD-A2-0721-

ECMA-C10807S (S=19mm)

ECMA-G11306S (S=22mm)

1000W ASD-A2-1021-

ECMA-C11010S (S=22mm)

ECMA-E11310S (S=22mm)

ECMA-G11309S (S=22mm)

1500W ASD-A2-1521- ECMA-E11315S (S=22mm)

2000W ASD-A2-2023-

ECMA-C11020S (S=22mm)

ECMA-E11320S (S=22mm)

ECMA-E11820S (S=35mm)

3000W ASD-A2-3023-

ECMA-E11830S (S=35mm)

ECMA-F11830S (S=35mm)

4500W ASD-A2-4523- ECMA-F21845S (S=35mm)

5500W ASD-A2-5523- ECMA-F218553 (3=42mm)

NOTE

1) The boxes () at the ends of the servo drive model names are for optional configurations (Full-closed loop,

CANopen and extension DI port). For the actual model name, please refer to the ordering information of the

actual purchased product.

2) The boxes () in the servo motor model names are for optional configurations (keyway, brake and oil seal).

[ Cable Specifications for Servo Drive

Power Cable - Wire Gauge mm

2

(AWG)

Servo Drive and Servo Motor

L1C, L2C R, S, T U, V, W P , C

ASD-A2-0221- ECMA-C10602S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C10604S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C108047 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-E11305S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ASD-A2-0421-

ECMA-G11303S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C10807S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ASD-A2-0721-

ECMA-G11306S 1.3 (AWG16) 2.1 (AWG14) 0.82 (AWG18) 2.1 (AWG14)

ECMA-C11010S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ECMA-E11310S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ASD-A2-1021-

ECMA-G11309S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ASD-A2-1521- ECMA-E11315S 1.3 (AWG16) 2.1 (AWG14) 1.3 (AWG16) 2.1 (AWG14)

ECMA-C11020S 1.3 (AWG16) 2.1 (AWG14) 2.1 (AWG14) 2.1 (AWG14)

ECMA-E11320S 1.3 (AWG16) 2.1 (AWG14) 2.1 (AWG14) 2.1 (AWG14)

ASD-A2-2023-

ECMA-E11820S 1.3 (AWG16) 2.1 (AWG14) 3.3 (AWG12) 2.1 (AWG14)

ECMA-E11830S 1.3 (AWG16) 2.1 (AWG14) 3.3 (AWG12) 2.1 (AWG14)

ASD-A2-3023-

ECMA-F11830S 1.3 (AWG16) 2.1 (AWG14) 3.3 (AWG12) 2.1 (AWG14)

ASD-A2-4523- ECMA-F21845S 1.3 (AWG16) 3.3 (AWG12) 8.4 (AWG8) 3.3 (AWG12)

ASD-A2-5523- ECMA-F21855S 1.3 (AWG16) 3.3 (AWG12) 13.3 (AWG6) 3.3 (AWG12)

Encoder Cable - Wire Gauge mm

2

(AWG)

Servo Drive

Wire Size Core Number UL Rating Standard Wire Length

ASD-A2-0221- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-0421- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-0721- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-1021- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-1521- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-2023- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-3023- 0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-4523-

0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

ASD-A2-5523-

0.13 (AWG26) 10 core (4 pair) UL2464 3m (9.84ft.)

NOTE

1) The boxes () at the ends of the servo drive model names are for optional configurations (Full-closed loop,

CANopen and extension DI port). For the actual model name, please refer to the ordering information of the

actual purchased product.

2) The boxes () in the servo motor model names are for optional configurations (keyway, brake and oil seal).

3) Please use shielded twisted-pair cables for wiring to prevent voltage coupling and eliminate electrical noise and

interference.

4) The shield of shielded twisted-pair cables should be connected to the SHIELD end (terminal marked ) of the

servo drive.

5) In order to prevent fire hazard and accidents, please form the wiring by following the cable specifications

outlined above.

\ Installation and Storage Conditions

The product should be kept in the shipping carton before installation. In order to retain the warranty coverage, the AC drive should

be stored properly when it is not to be used for an extended period of time. Some storage suggestions are:

Store in a clean and dry location free from direct sunlight.

Store within an ambient temperature range of -20°C to +65°C (-4°F to 149°F).

Store within a relative humidity range of 0% to 90% and non-condensing.

Do not store in a place subjected to corrosive gases and liquids.

Correctly packaged and placed on a solid surface.

Do not mount the servo drive or motor adjacent to heat-radiating elements or in direct sunlight.

Do not mount the servo drive or motor in a location subjected to corrosive gases, liquids, or airborne dust or metallic

particles.

Do not mount the servo drive or motor in a location where temperatures and humidity will exceed specification.

Do not mount the servo drive or motor in a location where vibration and shock will exceed specification.

Do not mount the servo drive or motor in a location where it will be subjected to high levels of electromagnetic radiation.

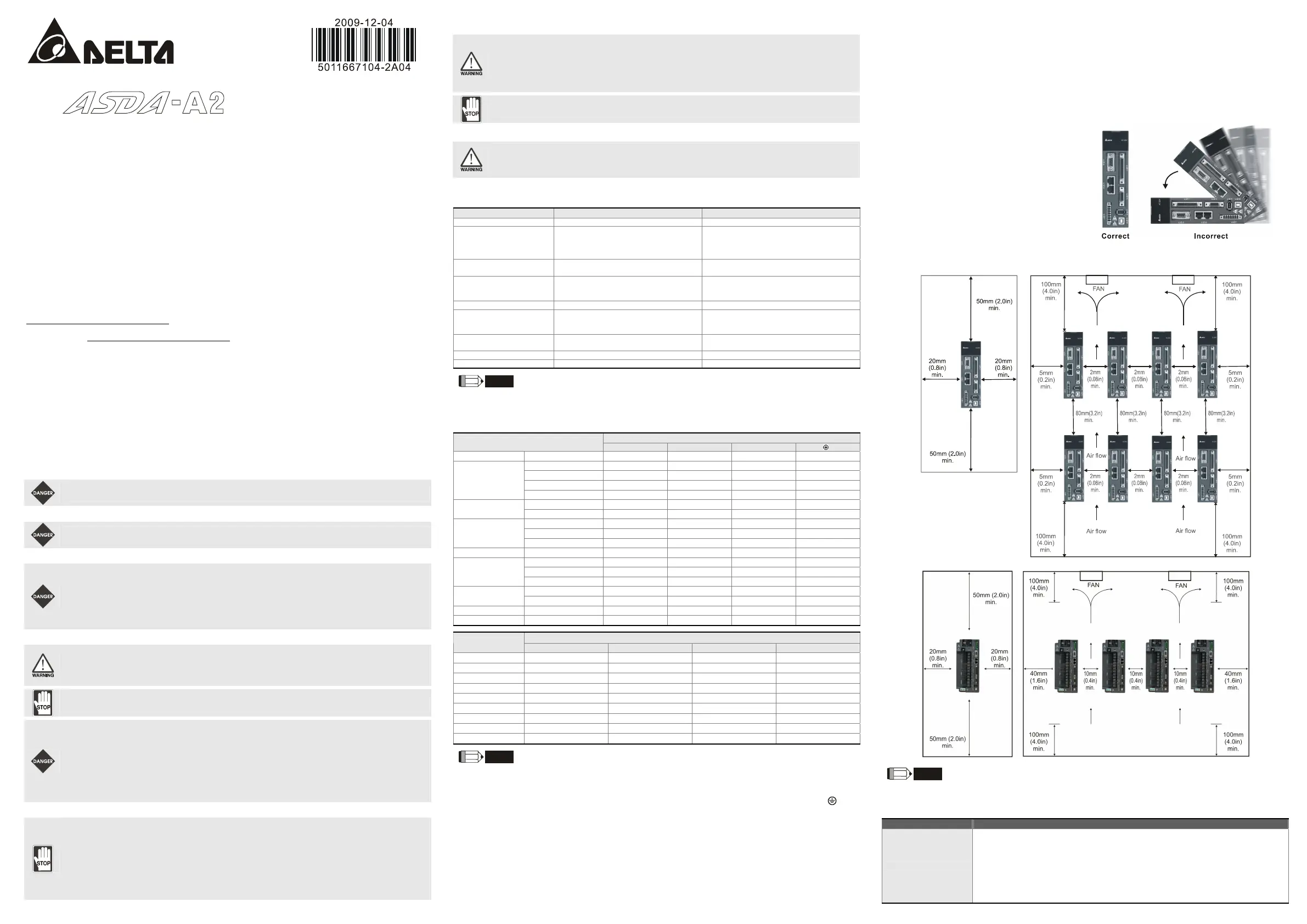

] Installation Note and Minimum Clearances

Installation Note:

Incorrect installation may result in a drive malfunction

or premature failure of the drive and or motor. Please

follow the guidelines in this instruction when installing

the servo drive and motor.

The AC servo drive should be mounted perpendicular

to the wall or in the control panel.

In order to ensure the drive is well ventilated, ensure

that the all ventilation holes are not obstructed and

sufficient free space is given to the servo drive.

Do not install the drive in a horizontal position or

malfunction and damage will occur.

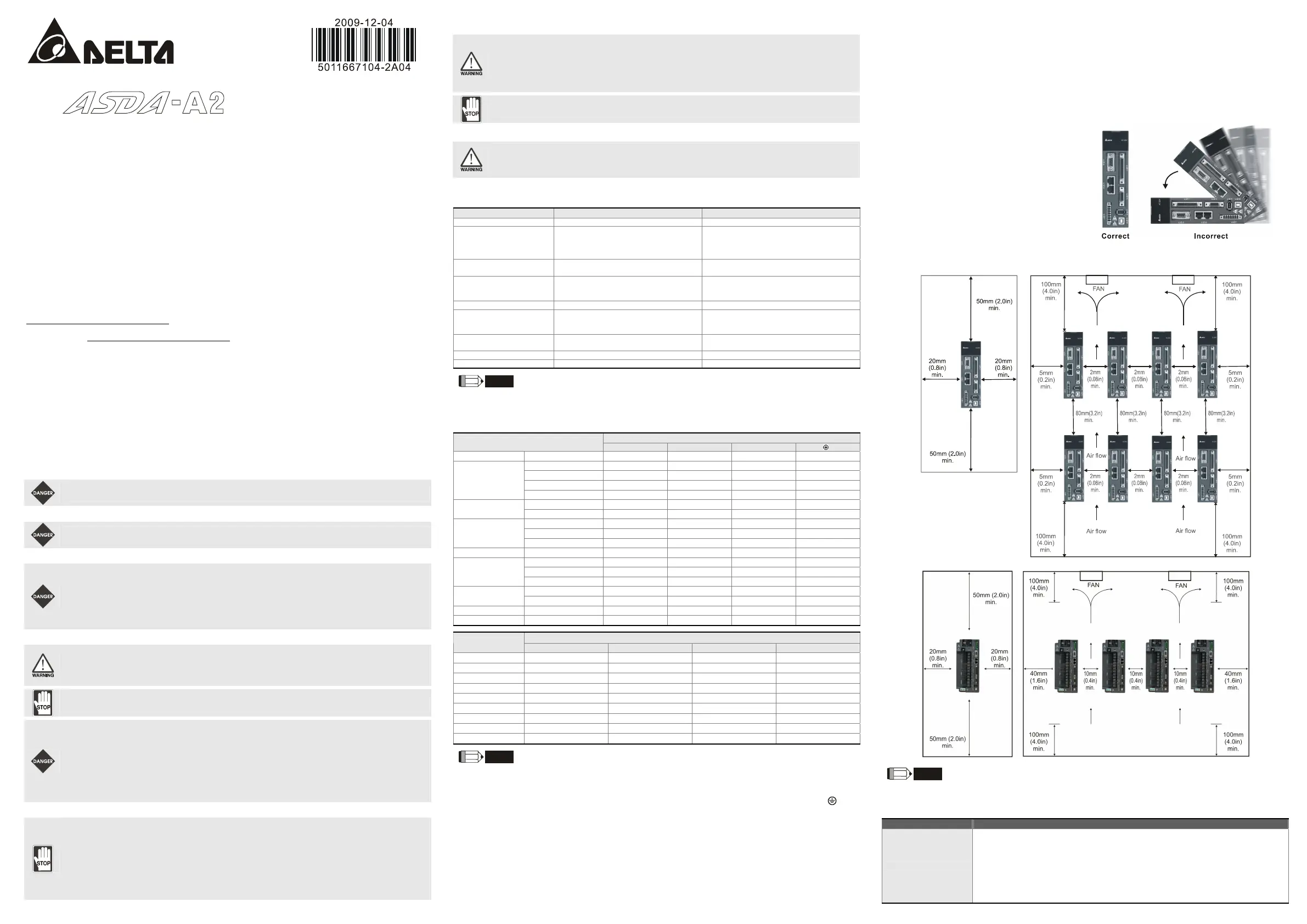

Minimum Clearances: Install a fan to increase ventilation to avoid ambient temperatures that exceed the specification. When

installing two or more drive adjacent to each other please follow the clearances as shown in the following diagram.

200W ~ 3kW models:

4.5kW ~ 5.5kW models:

NOTE

1) The scale of the clearances does not match the dimensions as shown in the drawing above. In the event of any

discrepancy between the clearances and the dimensions, the dimensions shall prevail.

^

Basic Inspection

After power in connected to the AC servo drive, the charge LED will be lit which indicates that the AC servo drive is ready.

Item Content

General Inspection

z Periodically inspect the screws of the servo drive, motor shaft, terminal block and the

connection to mechanical system. Tighten screws as necessary as they may loosen due to

vibration and varying temperatures.

z Ensure that oil, water, metallic particles or any foreign objects do not fall inside the servo drive,

motor, control panel or ventilation slots and holes. As these will cause damage.

z Ensure the correct installation and the control panel. It should be free from airborne dust,

harmful gases or liquids.

z Ensure that all wiring instructions and recommendations are followed; otherwise damage to the

drive and or motor may result.

Loading...

Loading...