Item Content

Inspection before operation

(Control power is not

applied)

z Inspect the servo drive and servo motor to insure they were not damaged.

z To avoid an electric shock, be sure to connect the ground terminal of servo drive to the ground

terminal of control panel.

z Before making any connection, wait 10 minutes for capacitors to discharge after the power is

disconnected, alternatively, use an appropriate discharge device to discharge.

z Ensure that all wiring terminals are correctly insulated.

z Ensure that all wiring is correct or damage and or malfunction may result.

z Visually check to ensure that there are not any unused screws, metal strips, or any conductive

or inflammable materials inside the drive.

z Never put inflammable objects on servo drive or close to the external regenerative resistor.

z Make sure control switch is OFF.

z If the electromagnetic brake is being used, ensure that it is correctly wired.

z If required, use an appropriate electrical filter to eliminate noise to the servo drive.

z Ensure that the external applied voltage to the drive is correct and matched to the controller.

Inspection during operation

(Control power is applied)

z Ensure that the cables are not damaged, stressed excessively or loaded heavily. When the

motor is running, pay close attention on the connection of the cables and notice that if they are

damaged, frayed or over extended.

z Check for abnormal vibrations and sounds during operation. If the servo motor is vibrating or

there are unusual noises while the motor is running, please contact the dealer or manufacturer

for assistance.

z Ensure that all user-defined parameters are set correctly. Since the characteristics of various

machines are different, in order to avoid accident or cause damage, do not adjust the

parameter abnormally and ensure the parameter setting is not an excessive value.

z Ensure to reset some parameters when the servo drive is off (Please refer to Chapter 8 of the

user manual). Otherwise, it may result in malfunction.

z If there is no contact sound or there be any unusual noises when the relay of the servo drive is

operating, please contact your distributor for assistance or contact with Delta.

z Check for abnormal conditions of the power indicators and LED display. If there is any

abnormal condition of the power indicators and LED display, please contact your distributor for

assistance or contact with Delta.

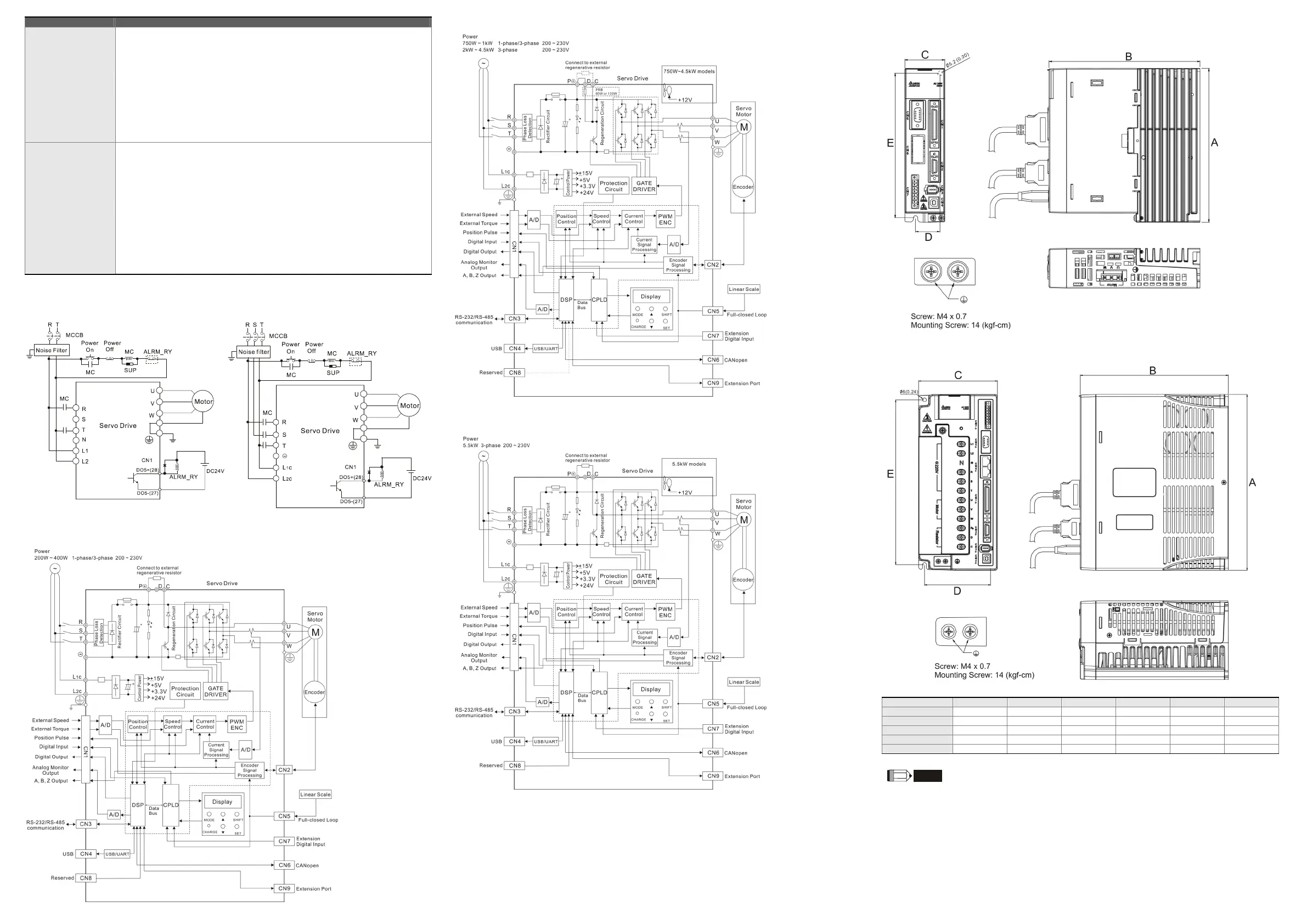

_ Wiring Methods

Single-Phase Power Supply Connection

(For 1.5kW and below models)

Three-Phase Power Supply Connection

(For all models)

` Basic Wiring

400W and below models (without built-in regenerative resistor)

750W ~ 4.5kW models (with built-in regenerative resistor and fan)

5.5kW models (with fan but without built-in regenerative resistor)

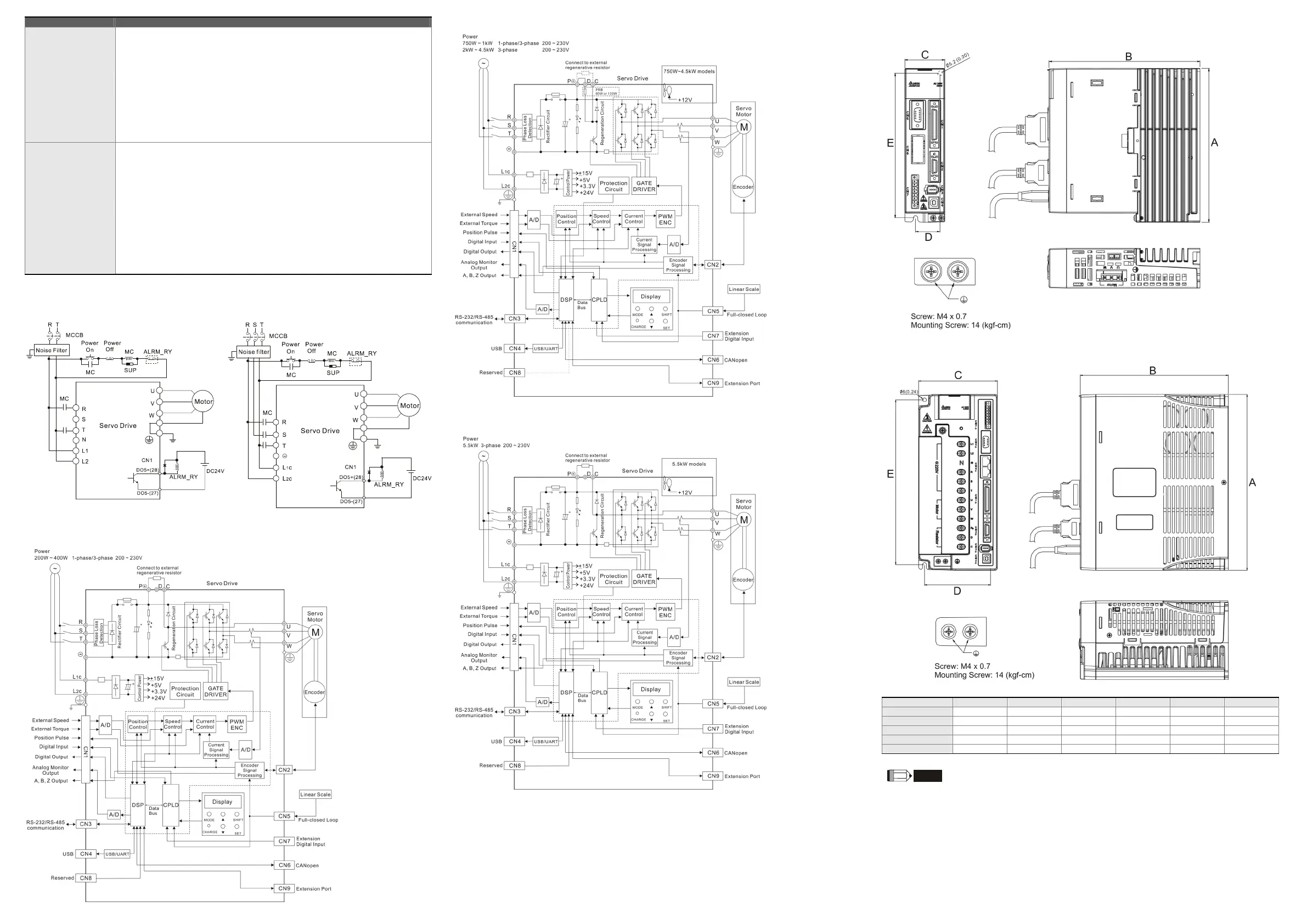

a Servo Drive Dimensions!

200W ~ 3kW models

4.5W ~ 5.5kW models

Power A B C D E Weight

200W ~ 400W 173 (6.81) 170 (6.69) 45 (1.77) 27.5 (1.08) 163 (6.42) 1.5 (3.3)

750W ~ 1.5kW 173 (6.81) 180 (7.09) 65 (2.56) 47 (1.83) 163 (6.42) 2.0 (4.4)

2kW ~ 3kW 216 (8.50) 203 (7.99) 82 (3.23) 62 (2.44) 203 (7.99) 2.89 (6.36)

4.5kW 245 (9.65) 206 (8.1) 110 (4.33) 91.2 (3.59) 229.5 (9.04) 3.0 (6.6)

5.5kW 245 (9.65) 205.4 (8.11) 123 (4.88) 107.0 (4.21) 230.0 (9.06) 5.5 (12.1)

NOTE

1) Dimensions are in millimeters and (inches).

2) Weights are in kilograms and (pounds).

3) For the actual appearance, please refer to the actual purchased product.

4) In this instruction sheet, actual measured values are in metric units. The units in (imperial units) are

for reference only. Please use metric for precise measurements.

Loading...

Loading...