Output of when in PID control mode (Ctrl = PID):

When the controller is in PID control and dual loop output mode,

parameter sets the P value of the 2nd set of PID. The 1st set of PID is generated when TUNE = AT, but user can also

manually set the PID value. The P value of the 2nd set of PID = the P value of 1st set of PID x . The I and D value of the

2nd set of PID remains the same as the 1st set of PID.

Control Mode Setting

There are 3 control modes, which are ON-OFF, PID, and MANUAL.

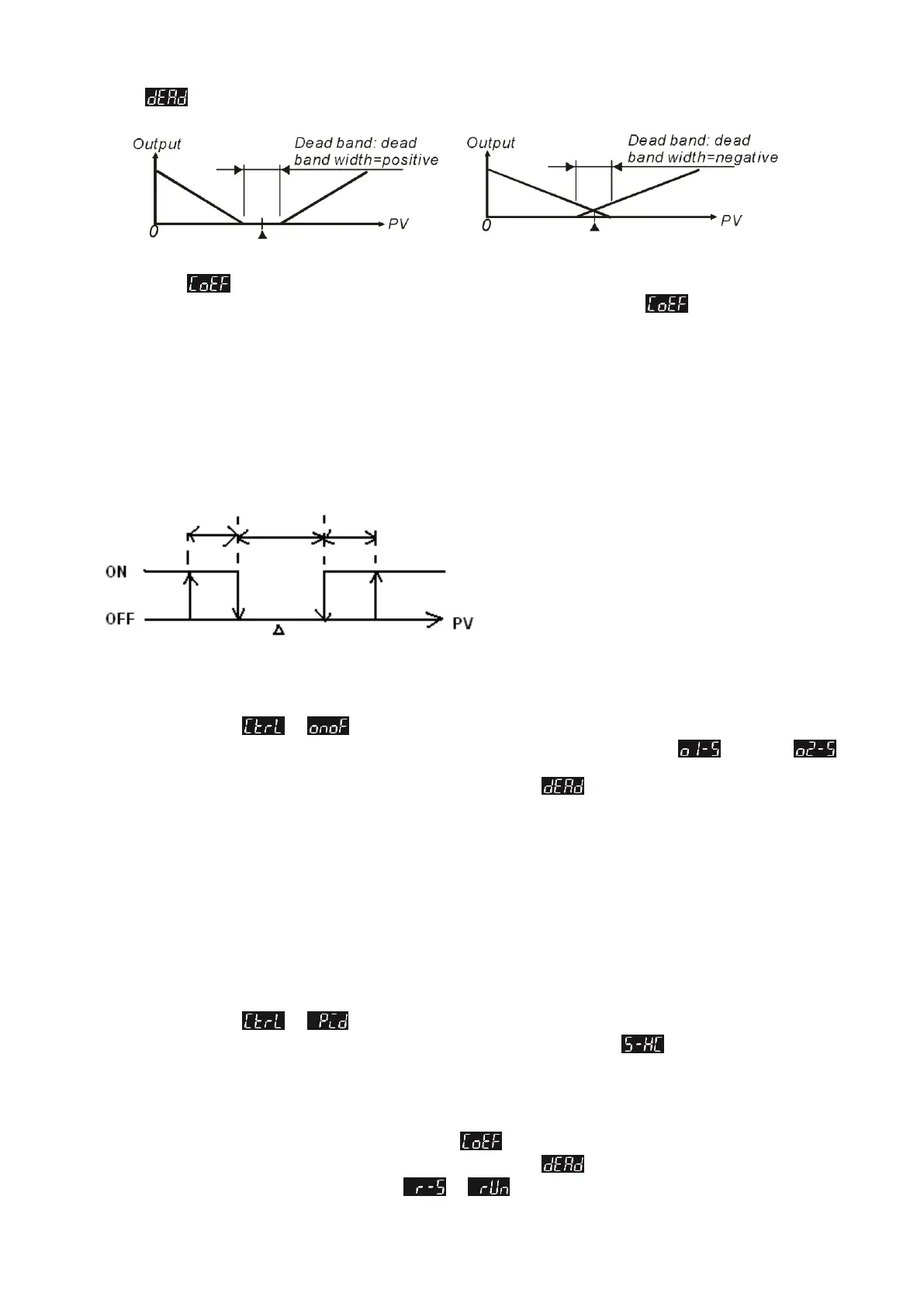

ON-OFF Mode: For heating output, the output is off when input is greater than the setting value; output is on when input is smaller

than (setting value - adjustment sensitivity setting value). For cooling output, the output is on when the input is greater than (setting

value + adjustment sensitivity setting value); output is off when input is smaller than the setting value. If one of 2 outputs is set for

heating and the other for cooling, a non-action zone can be set as shown in the diagram below.

Set parameter to in Initial Setting Mode.

Set adjustment sensitivity: Via parameter in Regulation Mode, set adjustment sensitivity (output 1),

(output 2).

Setting of Dead Band for both outputs: Set Dead Band via parameter in Regulation Mode.

PID Mode: When setting for heating or cooling, the program performs PID operation via input temperature and setting temperature,

with the operation result output for control of the temperature. A PID parameter and control period must be set for this function;

these parameters can also be generated automatically via auto-tuning (AT).

a. Set PID parameters and the control period: PID parameters can be adjusted manually according to system characteristics or

created automatically by AT. Proportional error compensation is used when I parameter is set to 0 for adjusting reduced

deviation from time to reach the temperature.The Control Period is the period of PID operation, if the control period is 10

seconds, it means a PID operation is carried out every 10 seconds. The result is then output to control the temperature.If the

system heats up quickly, the control period shall not be set too long. For relay output, lifespan of the relay shall be considered.

A short control period will shorten the lifespan of relay.

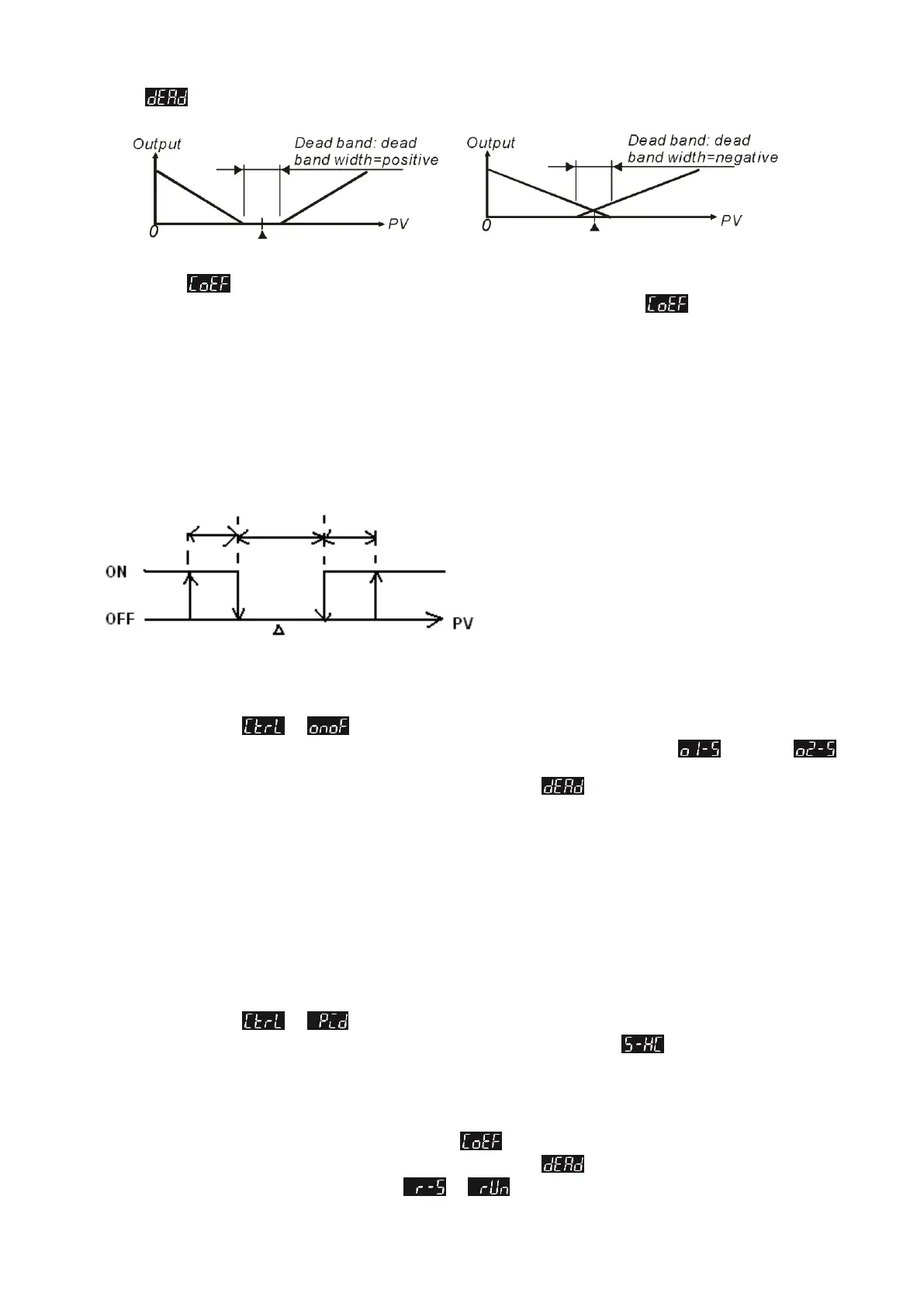

b. Coef and DeadBand are added in the PID parameter for double output (one for heating and one for cooling). Coef refers to

the ratio between the first and second portions of output (P parameter of second group = Coef*P, Coef = 0.01~99.99).

DeadBand is the overlapping temperature of the P output for the first and second group.

Set parameter to in Initial Setting Mode.

To set for heating or cooling control: Select desired output control via parameter in Initial Setting Mode. If only

single output control is performed, items to be selected are H1 and C1 (H for heating, C for cooling, and 1 for output 1). If

dual output control is performed, the items to be selected are as follows: H1H2, C1H2,... C1C2 (H for heating, C for cooling,

1 for output 1, and 2 for output 2).

Set control period: In Regulation Mode parameter, PV is displayed as "o'x' - 'y'". 'x' is 1 (output 1) or 2 (output 2). 'y' is H

(heating) or C (cooling).

Set double output Coef: Set Coef value via parameter in Regulation Mode.

Setting of Dead Band for both outputs: Set Dead Band via parameter in Regulation Mode.

Set control to running mode: Set parameter to in Operation Mode.

Loading...

Loading...