02/201410 / 72

6159933910

Issue no: 04

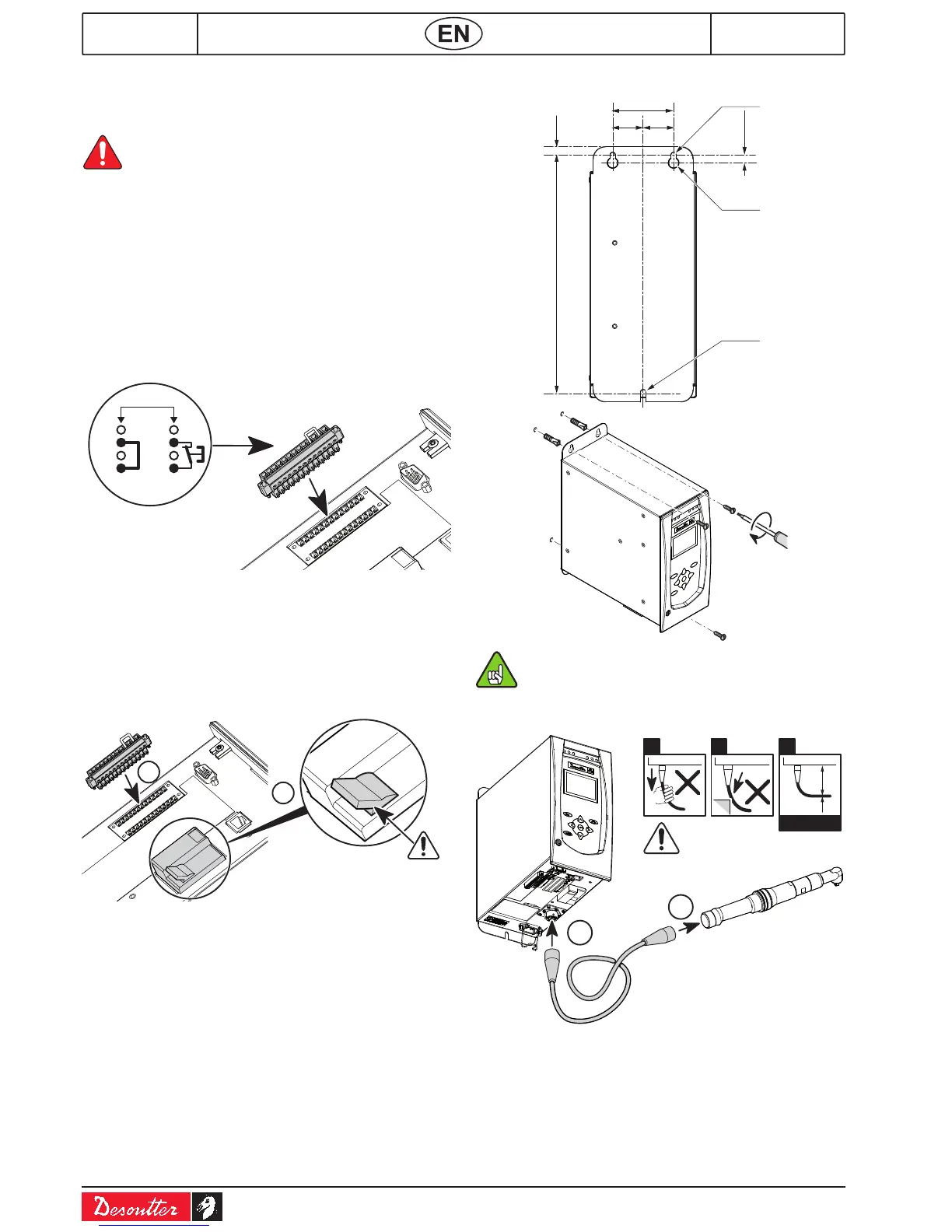

Check that the "STOP" signal is correctly connected to

the Input connector of the controller. The STOP can be

connected either to the PLC, or to a push-button close to

the tightening station.

If not connected, check that the jumper is correctly

positioned.

1

2

OR

3

4

1

1

13

2

3

4

The opening of the STOP contact disables the power

circuit.

Note that it is recommended to wire the STOP when using

handheld tools, but that it is absolutely necessary for xed

tools.

OFF

1

2

10

9.75

292

75

Ø6.5

= =

Ø6.5

Ø13

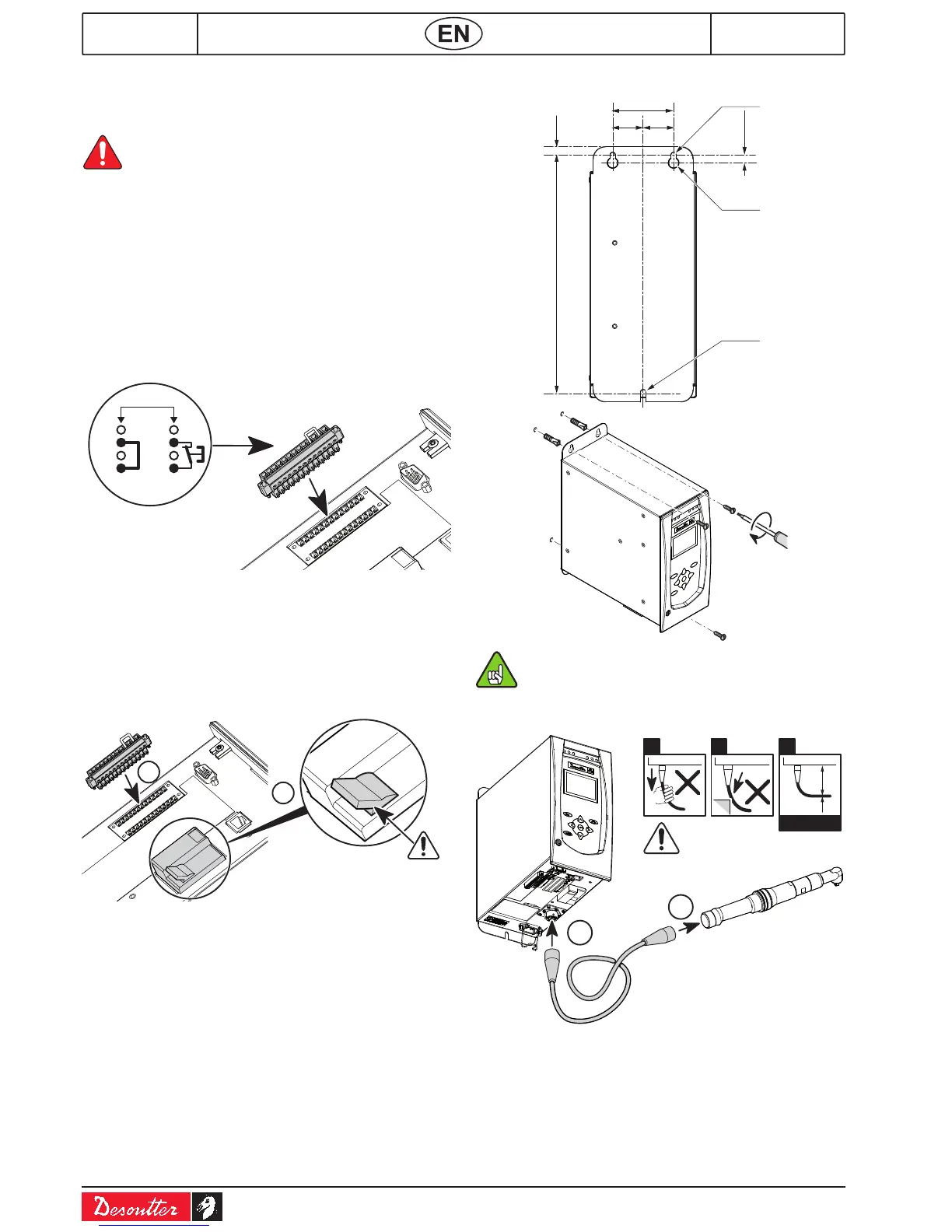

Make sure the fasteners are adapted to support

and to the device.

1

2

Ød

D

a b c

Although our cables are designed to work under drastic

conditions, we recommend that you check the following

points for longer service life:

● Bending radii should not be lower than 10 times the

cable diameter (c).

● Friction with the outer sheath should be restricted (b).

● Any direct pull on the cable should be avoided (a).

Loading...

Loading...