29

English

1� After the recommended period of time (in accordance with the manufacturer’s instruc-

tions), use a damp cloth to clean off any remaining disinfectant from the components

and then dry them�

2� Attention! Heated steam accelerates the ageing process of plastics� Changes in material

can affect the functionality of the device parts�

3� Remove the deposits or solids from the float chamber, valve seat and valve unit with

tweezers� Rinse all parts thoroughly under running water�

Examples of surface disinfectants:

Incidin® Plus *

Incidin® Perfect *

Antiseptica Combi surface disinfectant *

Antifect® FF *

B 10 *�

Examples of instrument disinfectants:

Lysetol® AF *

Gigasept® FF *

Sekusept® forte S*

* registered trademark of that particular manufacturer

All individual parts must be rinsed with distilled water after use�

Single use items must not be re-used, as there is a risk of infection� The above-mentioned

disinfecting examples are suggestions from the equipment manufacturer� The recommen-

dation is the named active agent bases (pH 4�5 to 8)� This does not absolve the user from

the responsibility to ask the hygiene experts, in individual cases, to test the suitability of

the active agents on a component to be disinfected�

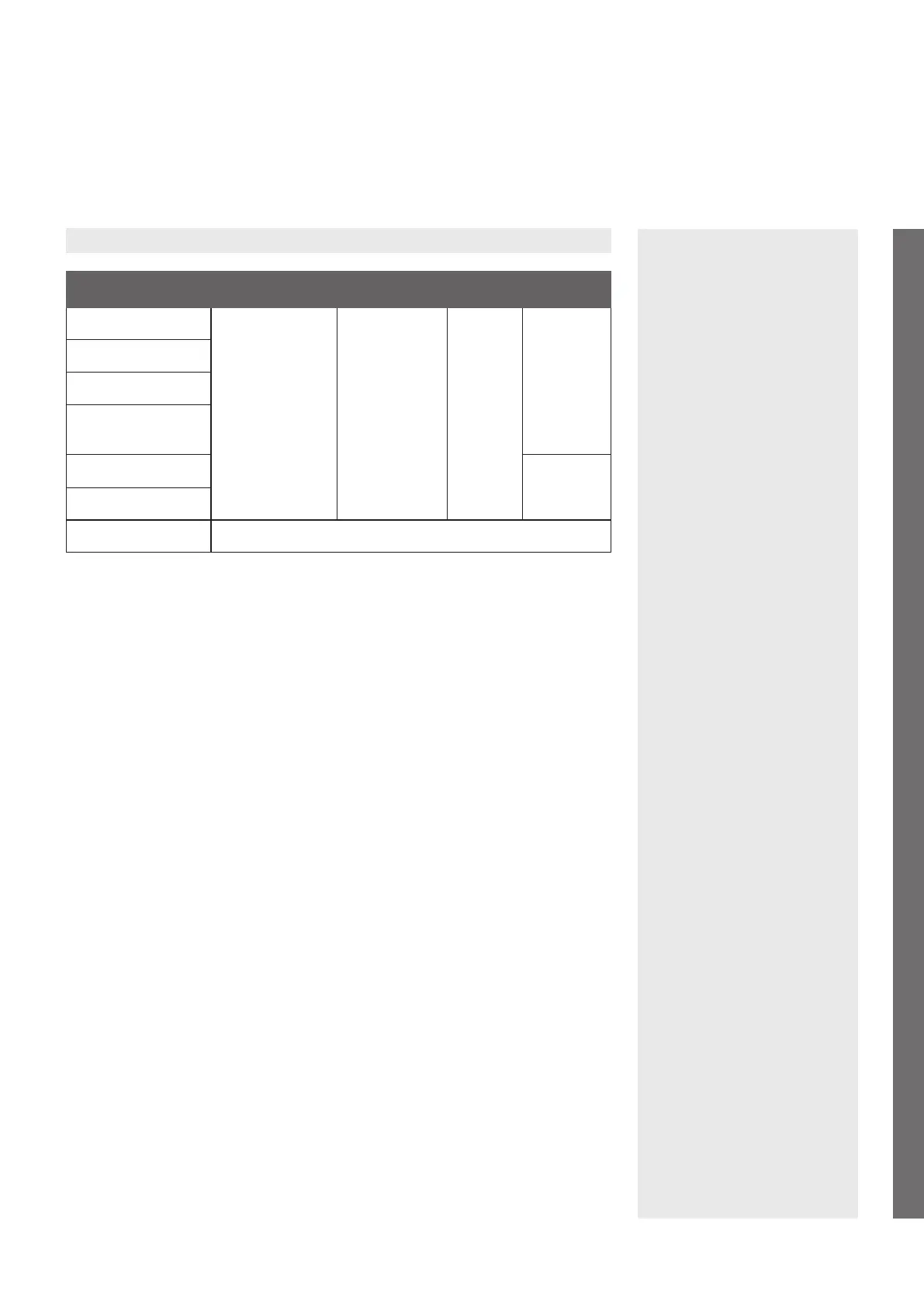

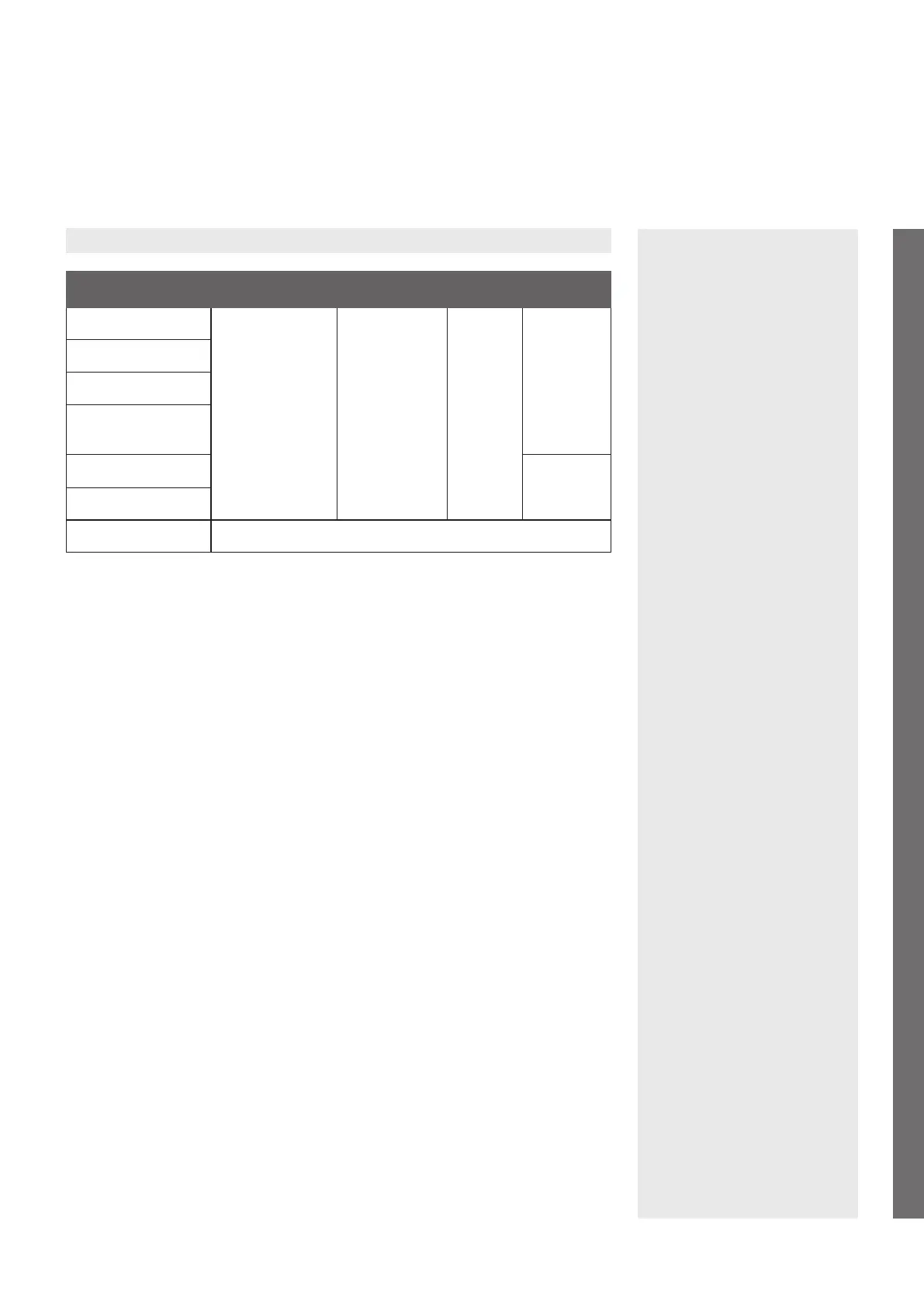

How to clean the continuous filling kit

Nebuliser chamber In warm

water

with mild

household

cleaner

Immerse

in diluted

solution

Rinse

cycle

up to

95° C

Up to

121° C

max�

20 min

Screws

O-ring

Nebuliser chamber

cover

Valve unit Not per-

mitted

Float

Connectors Only to be used once

Components Cleaning Disinfecting

2

Dish-

washer

Hot steam

sterilisation

3

Loading...

Loading...