43

VALVE MAINTENANCE

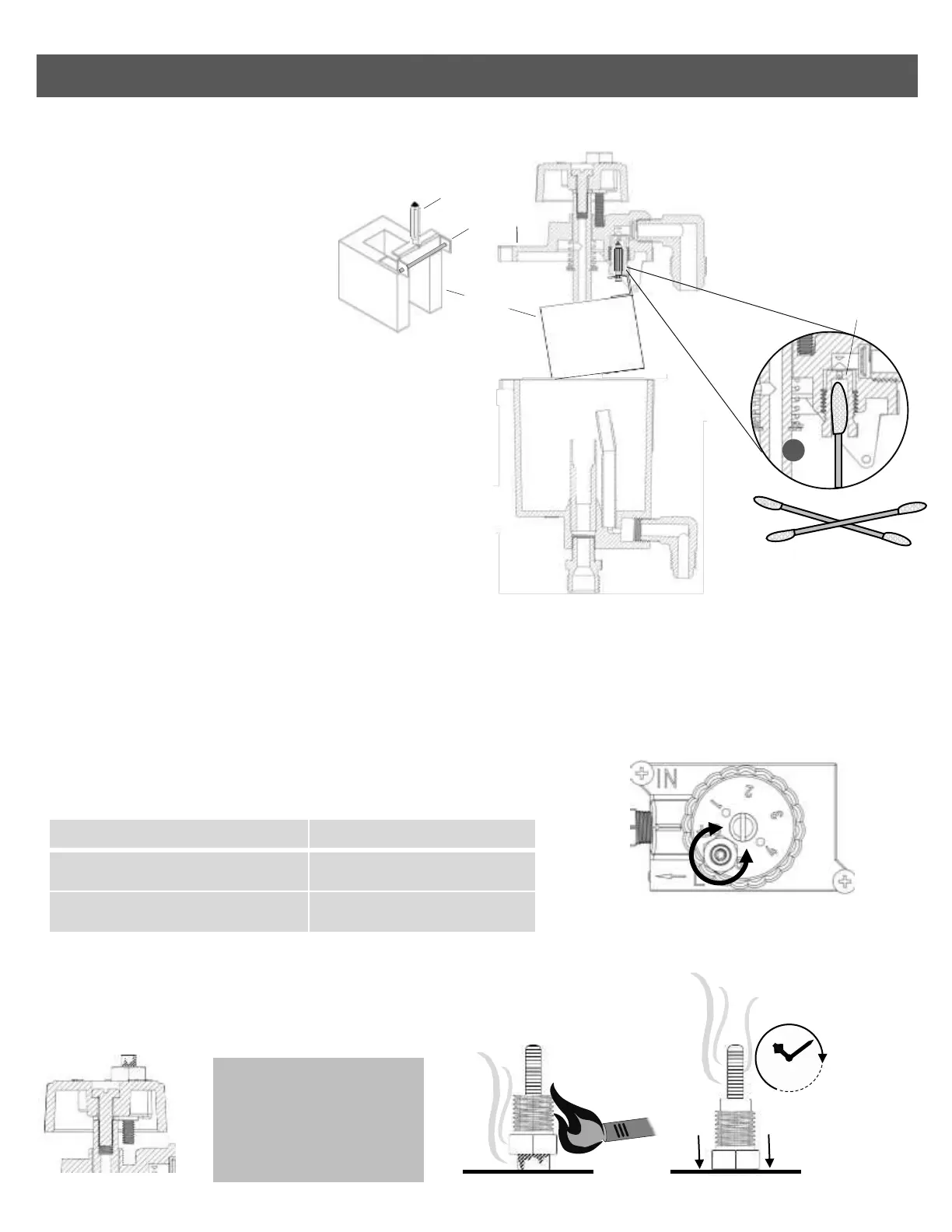

Valve maintenance

The job of the metering valve is to maintain a steady oil level within the valve &

burner, and to precisely meter out the correct amounts of fuel for each

numbered fuel setting. In order to function as intended, the metering valve

must be kept clean.

COOL

When should you clean the metering

valve?

It is a good idea to clean the metering valve at the

start of every season, if the appliance has sat unused

for long enough to allow fuel inside the metering

valve to dry out leaving sticky residue, or if fuel flow

issues are noticed.

How to clean the metering valve

To restore the metering valve to proper functioning, the needle and seat must

always be cleaned. The seat accumulates layers of dried fuel residue over time,

which eventually cause the movement of the needle inside to become sticky. To

clean the seat;

Lid

Detach the inlet fuel line and remove the screws holding on the lid of the valve.

The lid comes off with the float, float pin and needle attached. Slide the float pin

out to release needle and float from the valve lid.

With the needle removed, clean the seat that houses the needle repeatedly until

a cotton swab comes away clean (1) Make sure the cotton swabs penetrate all

the way into the seat tube and twist thoroughly to polish away any fuel residue.

DO NOT use any cleaning agents or solvents to clean the valve as these may

damage rubber seals used in the device.

DO NOT remove the seat for cleaning, the height of the seat must not be altered

by loosening or tightening it down.

The spring loaded metering stem does not need to be removed from the lid in

order to clean the valve.

Reassemble the valve complete with the float, float pin and needle as shown

above.

Needle

Float pin

Float

1

Seat

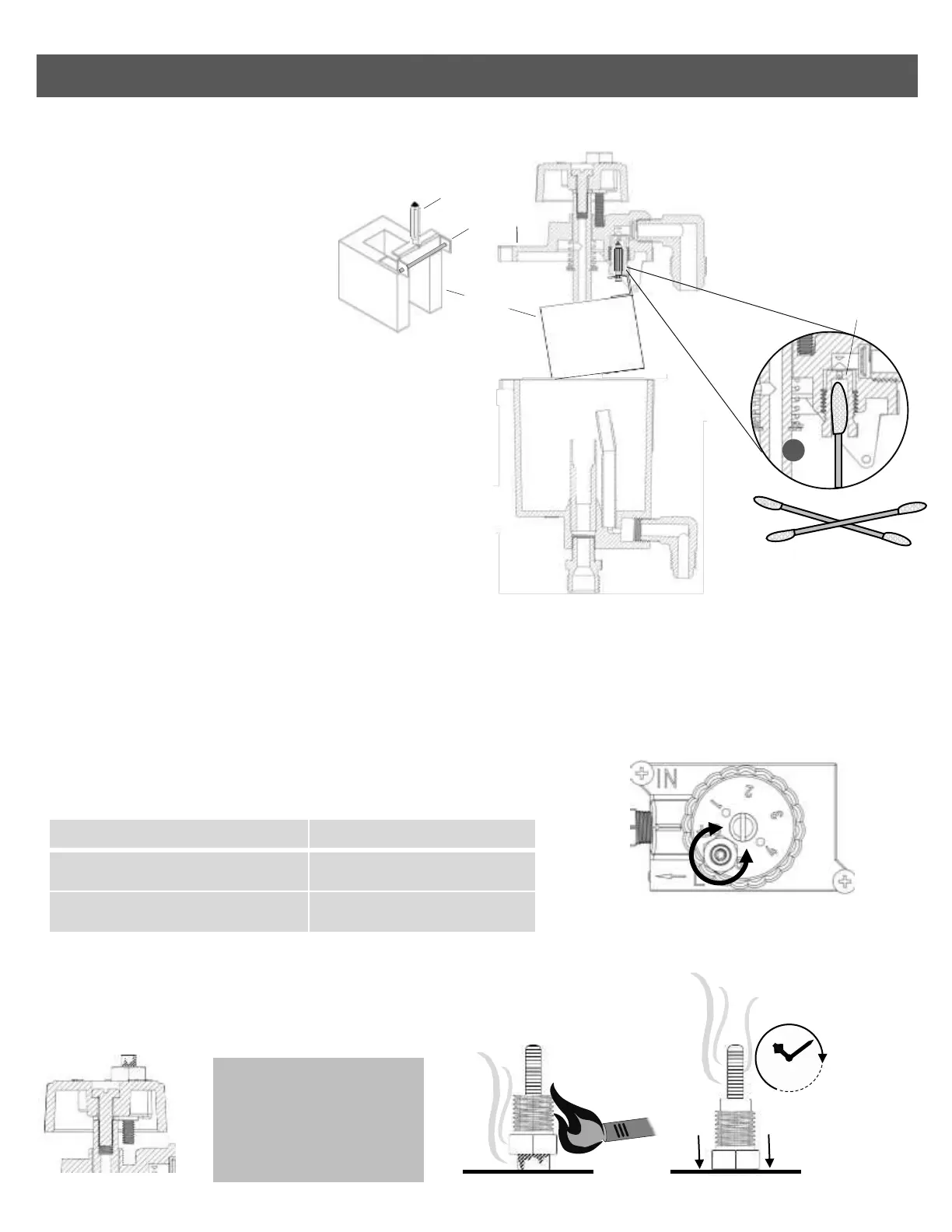

Calibrating and adjusting the metering valve

Cleaning the seat of the metering valve will correct the oil level if it was previously inconsistent. If the valve was calibrated or adjusted prior to cleaning, the calibration

will need to be adjusted again in order to meter fuel in the correct amounts.

To calibrate the valve, use a 2mm allen key to turn the calibrating screw in small increments clockwise (to increase fuel flow) or in small increments counter-clockwise (to

decrease fuel flow) Note: to gain access to the calibrating screw, a smaller locking screw will first have to be removed.

+

_

Valve type/Appliance Flowrate on setting #1 (lowest setting)

3D /

All heaters & stoves except 00-ATL

Should produce approx. 1 Tsp every 60

seconds

4D /

Atlantic stove

Should produce approx. 1 Tsp every 50

seconds

Detach the fuel line leading from the metering valve to the burner where it connects to the valve. This

will allow fuel to drip straight down from the outlet of the metering valve so it can be measured. Follow

the steps below and use the allen key to adjust the valve flow-rate to the match the correct flow-rate

for your valve listed on the chart.

Use 2mm (0.78”) allen key to first remove the locking screw. Then turn

the calibrating screw in small increments clockwise (to increase flow) or

counter-clockwise (to decrease flow)

Resetting the high-fire fuse

The valve knob is equipped with a safety fuse designed to come apart & stop fuel supply if it becomes overheated. If the

appliance runs too hot and shuts off, check the fuse for signs that it has been sprung due to overheating (fig 89) To reset

the fuse, place it upside down in a pan until its solder melts and the nut drops back into place (fig 90) Allow the fuse

ample time to cool before handling after resetting! (fig 91)

If a fuse has lost all its low-temperature solder it will not be possible to reset it.

Before the fuse is reset and

reattached, make sure you

have cleaned & calibrated

the metering valve to

prevent the appliance from

overheating again!

FIG 85

FIG 86

FIG 87

FIG 88

cotton swabs

FIG 89

FIG 90

FIG 91

Loading...

Loading...