44

FUEL PUMP MAINTENANCE

Cleaning

Cleaning the pump is the best method to ensure it will remain in

good working order over its lifetime. The pump comprises a tube

inside which a magnetic plunger moves up and down to draw

fuel, while several check valves inside ensure fuel flows in the

desired direction. If fuel delivery from the pump becomes

inconsistent, check and lubricate each check valve to ensure they

can open letting fuel enter and leave the pump.

4

5

Insert upside-

down then

flip!

1

Plunger

Spring

Spring

Check-valve

2

3

6

7

FUEL PUMPS

In order to supply the appliance reliably a fuel pump

must receive filtered fuel. It is best to orient the fuel

pump so that it must draw fuel upwards from a source

below.

The electrical components inside the fuel pump are

permanently sealed to isolate them from the fuel

running through the pump.

Air Leaks

Vibrating or chattering pump activity

means that the pump is drawing in

air as well as fuel. The location of

such a leak will always be on the

pressure side of the pump –

between the pump and the fuel

source. Any leaks must be carefully

located and fittings tightened or

lines repaired to eliminate the issue.

Disassembly & Cleaning

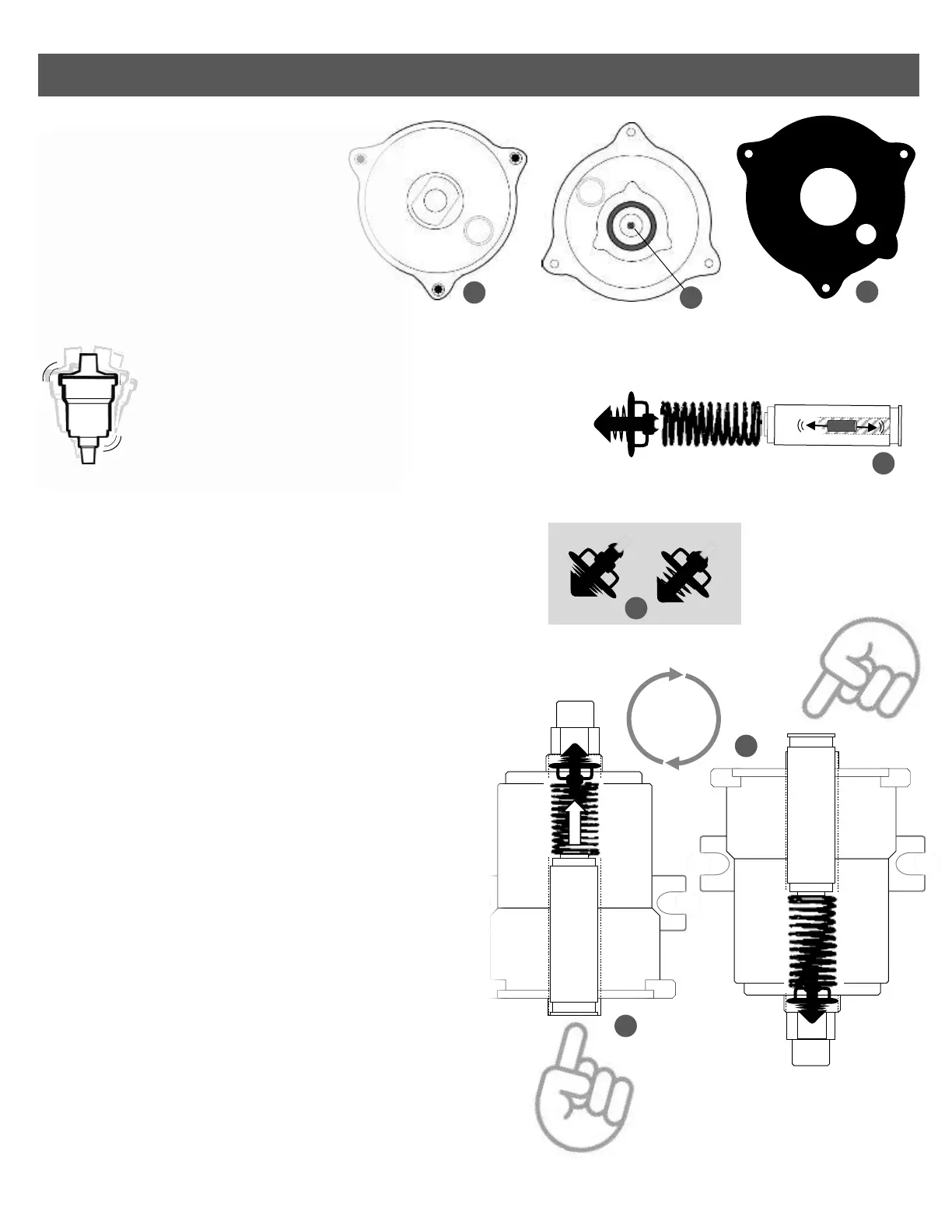

• The lid of the pump is held on by 3 torx screws (1) Remove these &

hold the pump with its inlet upwards and twist to remove the lid.

Inside you’ll find all the pumps moving parts – spring plunger and

spring check valve.

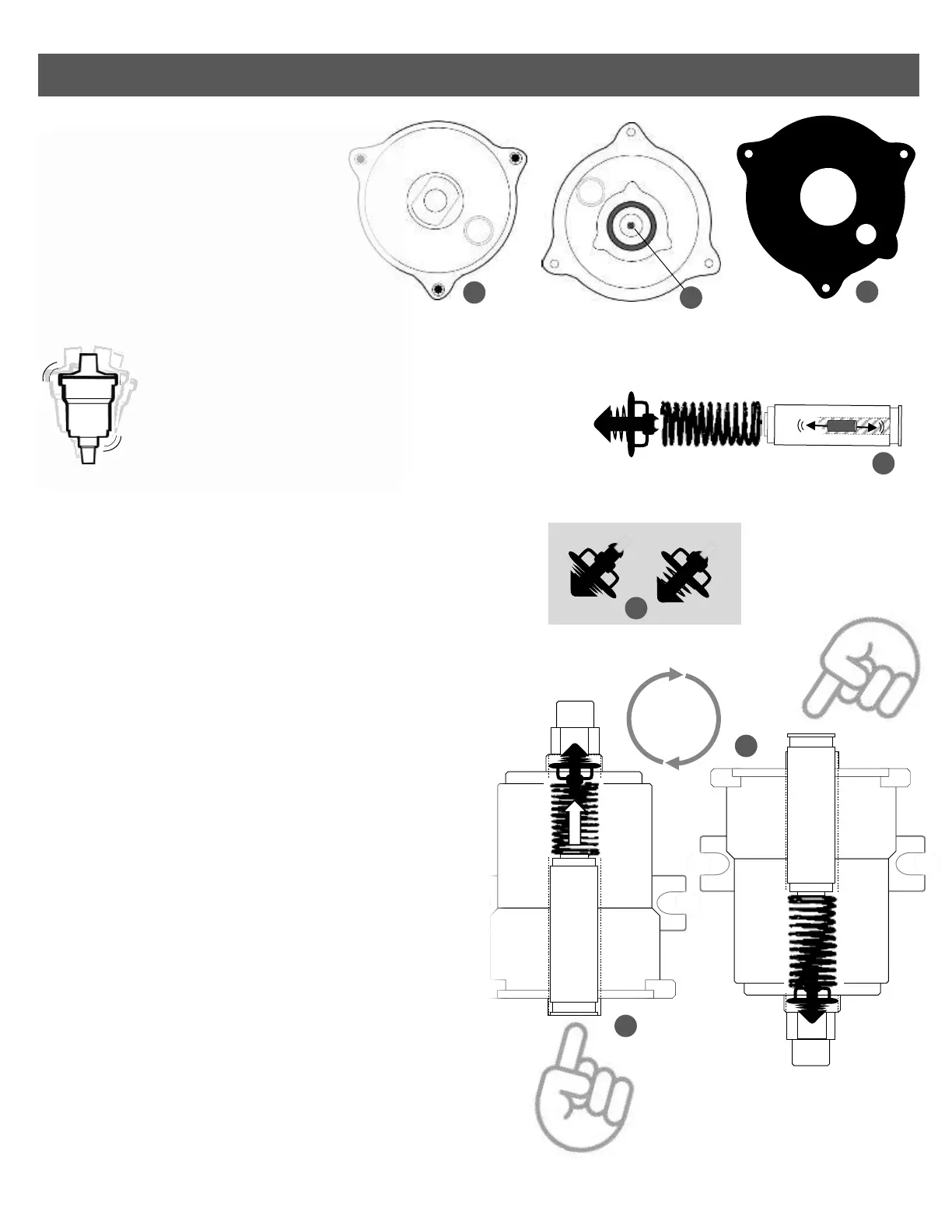

• Remove and shake the magnetic plunger (2) – movement should be

heard and felt inside it. This movement indicates that the check

valve inside the plunger is working

• The spring check valve should be assembled with a small spring and

able to compress and spring back to shape (3)

• Verify that both these check valves are operational, then turn the

pump upside-down and carefully reinstall the pumps parts in the

order shown (4) Insert the components all the way with a finger

and hold them in place while you flip the pump back to right side

up (5) This will prevent the spring check valve from becoming

dislodged inside the pump.

• Before reinstalling the lid press on the small hole in its center (6) –

the small steel ball located here is the 3

rd

check valve, and should

give way when pressed in and spring back into place.

• Lubricate the inside of the pump thoroughly with WD-40 before

reassembling. Line up the lid gasket (7) carefully under the pump lid

before tightening the screws in place.

FIG 92

FIG 93

FIG 94

FIG 95

FIG 96

FIG 97

Loading...

Loading...