6.2 IN-LINE VALVE INSTALLATION:

Operating pressure when used with DIG in-line valves: 10-150 PSI

(.7 to 10.5 bar)

Recommended operating pressure: Up to 80 PSI (5.5 bar)

NOTE: Wrap all fittings with Teflon tape. Do not use pipe cement on the

valve as this will damage the valve and void the warranty. Make sure when

wrapping fittings with Teflon tape that no excess gets into the internal

assembly. Tighten the fittings with a wrench but do not over tighten.

1. Shut off main water supply.

2. Install a manual ball or gate valve onto the PVC pipe upstream of the valve

manifold. Use Teflon tape to wrap all male threads with 4-6 layers of

Teflon tape.

3. Turn water supply on to flush the line and then shut the water off using the

ball or gate valve. If PVC glue is used, make sure to allow for adequate curing

time before opening the water supply line.

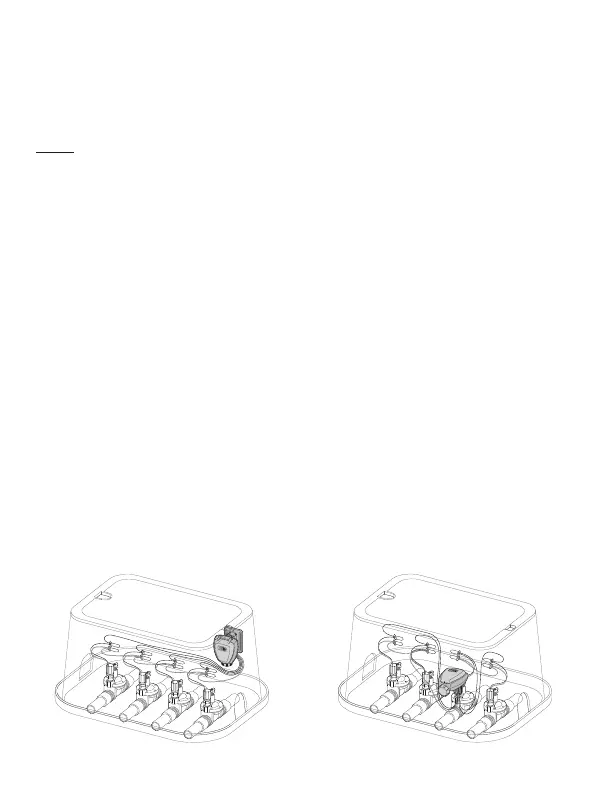

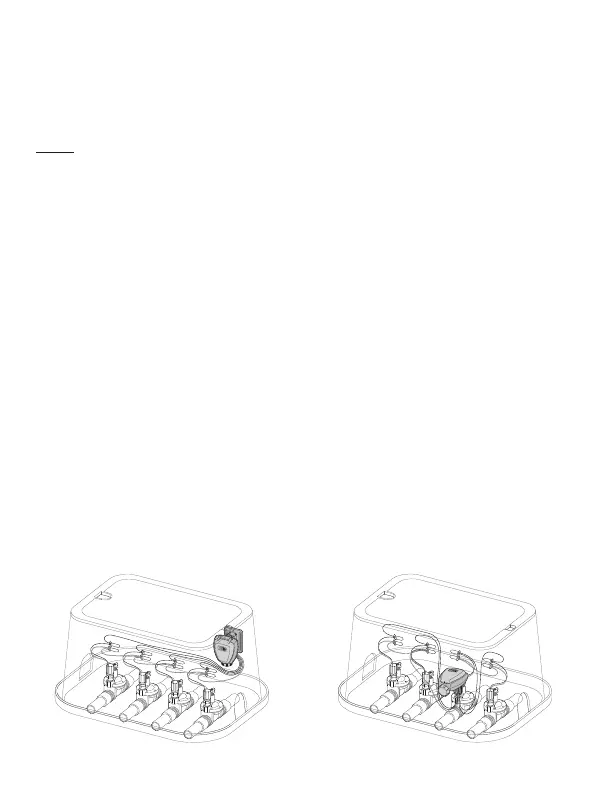

4. Make a manifold and install up to six inline valves and mount the controller to

the valve box or the solenoid (Figure H and I).

5. Mount the controller using the solenoid mounting and connect the wires: refer

to section 4.1 on page 3 for wire connection steps.

6. Test each valve via the controller: refer to section 10.1 on page 27 for how to

perform a manual run.

6

BELOW GROUND INSTALLATION WALL MOUNTING

FIGURE H

BELOW GROUND INSTALLATION VALVE MOUNTING

FIGURE I

Loading...

Loading...