HI, MI, WI-700 service manual - 6 – maintenance schedule

6-3 Issue 9 04/2020

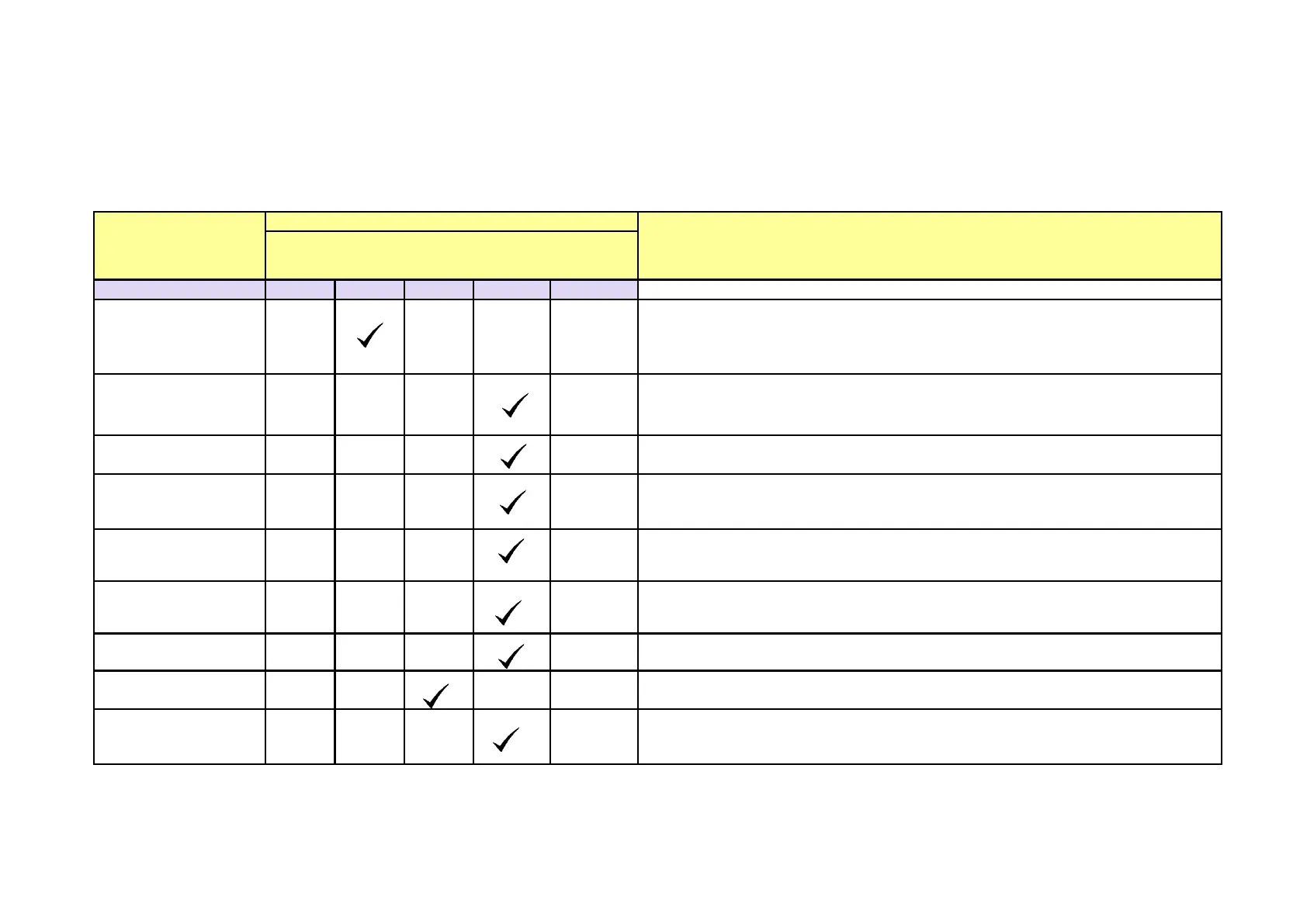

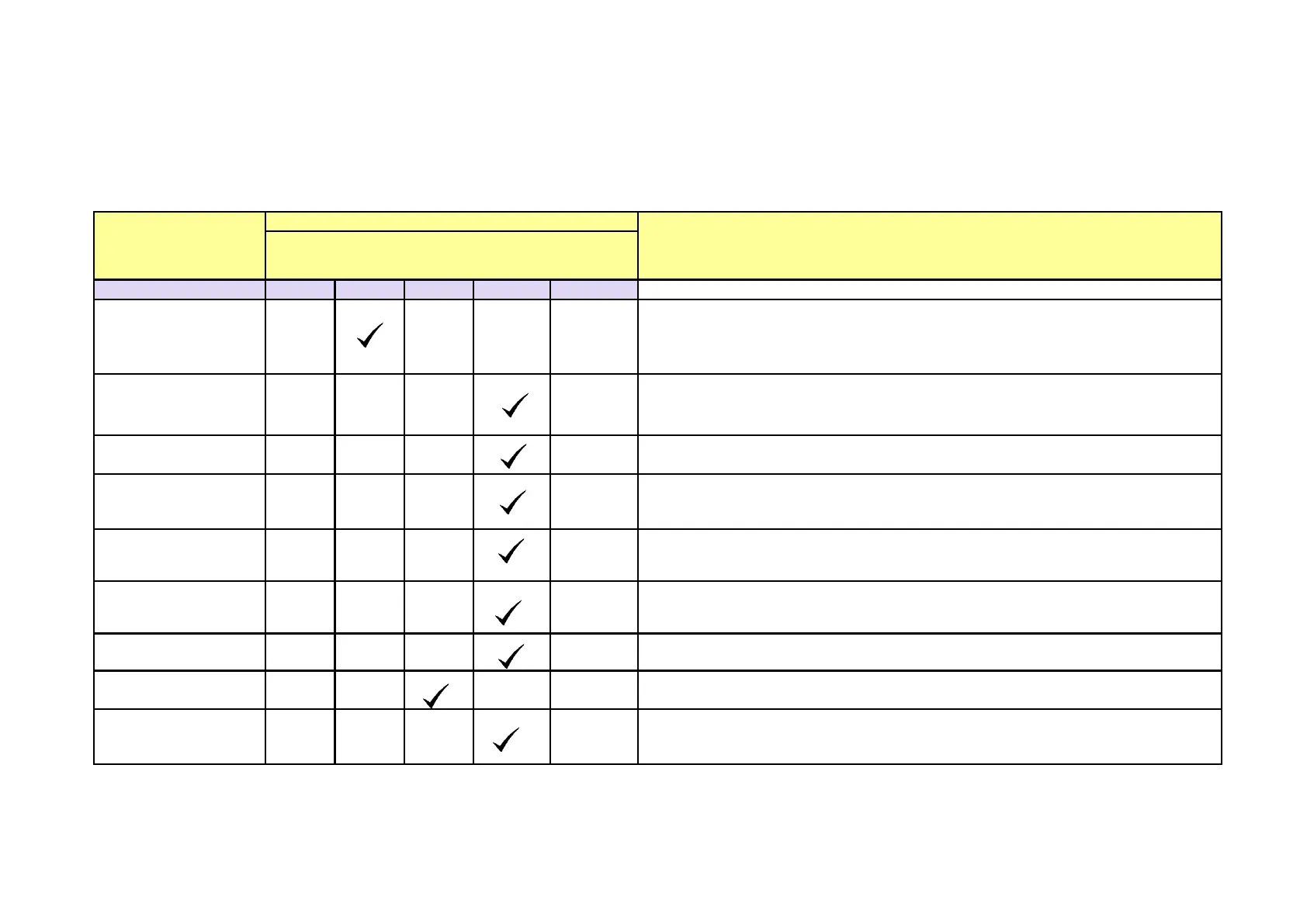

700 SERIES MACHINE ROUTINE MAINTENANCE SCHEDULE

Note: based on a 16-hour day. Daily & yearly checks to be carried out regardless of actual running time.

Weekly, monthly & 3 monthly intervals may be adjusted to suit actual machine running time.

MACHINE AREA /

COMPONENT

FREQUENCY OF TASK

DETAILS OF TASK

3

DAILY WEEKLY MONTHLY MONTHLY YEARLY

ALL CONVEYORS

CONVEYOR BELTS

Check belts are in good condition. Check for rips in belt material and degrading of

elastic properties. Note: poor condition belts can cause unstable weighing, poor

pack transportation and label positioning. (for cleaning of belts refer to routine

maintenance section in service manual)

DOUBLE SIDED

TOOTHED DRIVE

BELT

Check condition, if any signs of damage / wear, replace.

Check correct tension of belt (use setting tool 562-546) Refer to servicing section

in manual for setting.

MOTOR DRIVE BELT Check condition, if any signs of damage / wear, replace.

Check tension of belt

END BEARINGS IN

CONVEYOR

ROLLERS

Ensure all run freely – remove conveyor belts and spin rollers to check.

CONVEYOR

PULLEYS - metal

bearings type

Check condition of pulleys and bearings.

CONVEYOR

PULLEYS - plastic

bush type

Check condition of pulleys and plastic bushes.

Disassemble each pulley and lubricate bushes.

DRIVE PULLEY

BEARINGS

Check for play in shaft and bearing assembly and that the pulley turns freely

CONVEYOR ANTI-

FRICTION TAPE

Remove conveyor belts and check tape for wear. Replace the tape if worn /

damaged or lifting from conveyor deck.

CONVEYOR SPRING

LOADED LOCK

Lubricate sliding mechanism – remove conveyor from machine, compress sprung

loaded end and lubricate moving parts. (Refer to parts manual for detail)

Loading...

Loading...