HI, MI, WI-700 service manual - 6 – maintenance schedule

6-9 Issue 9 04/2020

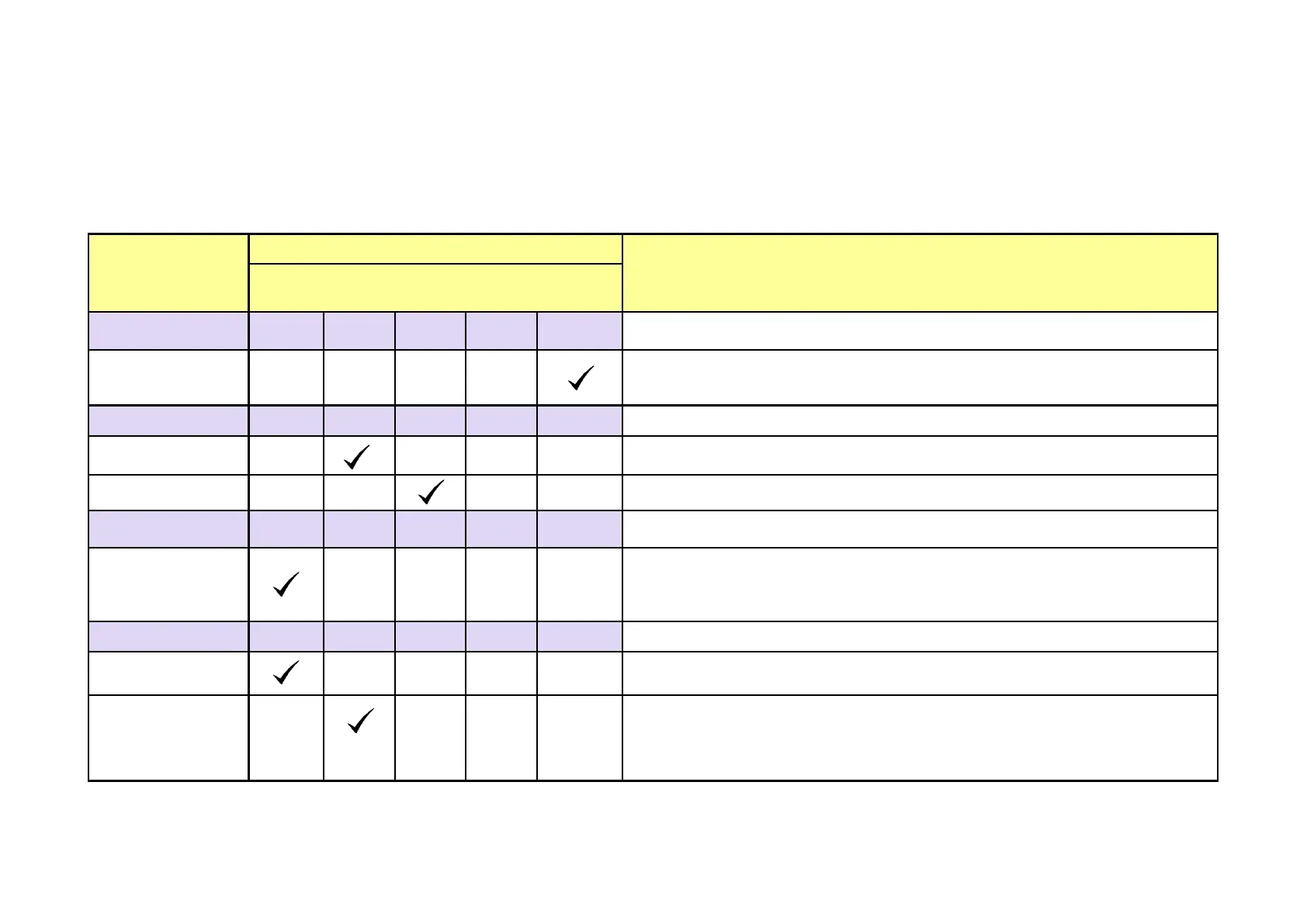

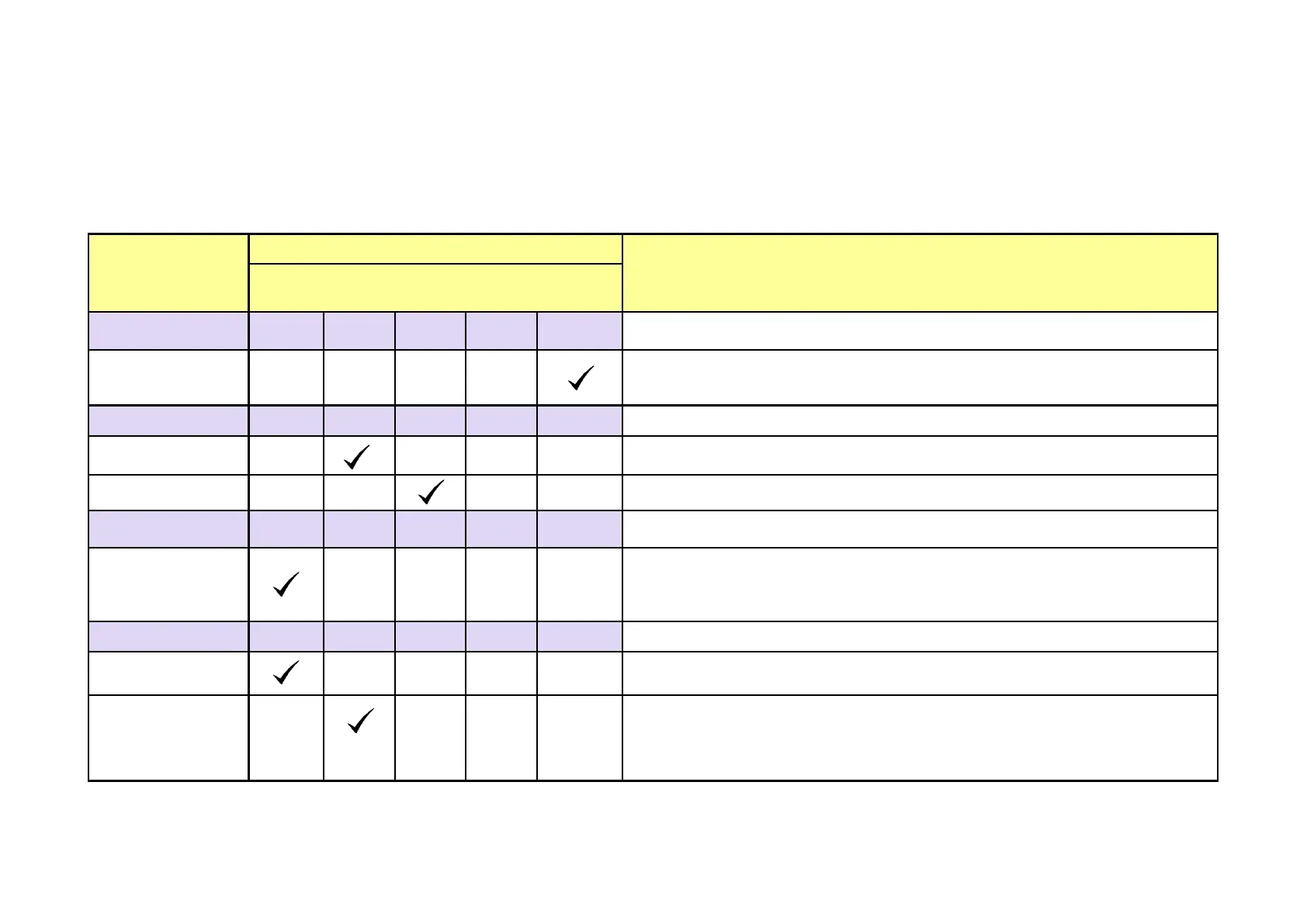

700 SERIES MACHINE ROUTINE MAINTENANCE SCHEDULE

Note: based on a 16-hour day. Daily & yearly checks to be carried out regardless of actual running time.

Weekly, monthly & 3 monthly intervals may be adjusted to suit actual machine running time.

MACHINE AREA /

COMPONENT

FREQUENCY OF TASK

DETAILS OF TASK

3

DAILY WEEKLY MONTHLY MONTHLY YEARLY

LABELLER

LIFTING GEAR

LEAD SCREW /

BEARINGS / BUSH-

ES

Remove lifting gear cover to check condition of lead screw and bearings.

Clean and lubricate with grease.

Check micro switches for travel limit are working. (Refer to parts manual for detail)

TOUCH SCREEN

CLEAN Clean touch screen, use appropriate cleaning solution for screen surface.

CALIBRATION Check the accuracy of touch points. Re-calibrate if required.

AIR REGULATOR

DRAIN AND BOWL

CLEAN

Check auto drain, clean bowl (warning – ensure bowl is cleaned with a suitable

cleaner that will not attack the polycarbonate bowl).

The cleaning / changing of filter interval is dependent on how clean the air supply is

to the regulator.

PACK SENSORS

REFLECTOR Clean reflector. Check for water ingress to reflector

WENGLOR PHO-

TOELECTRONIC

SENSORS OR

FIBRE OPTIC

SENSOR

Check for any damage. Check sensitivity of sensor is correct for customers pack

and sensor is mounted securely. (Refer to 700 service manual, component parts

section, pack sensor amps)

Loading...

Loading...