Faults -7

Version 1.36

02/2004

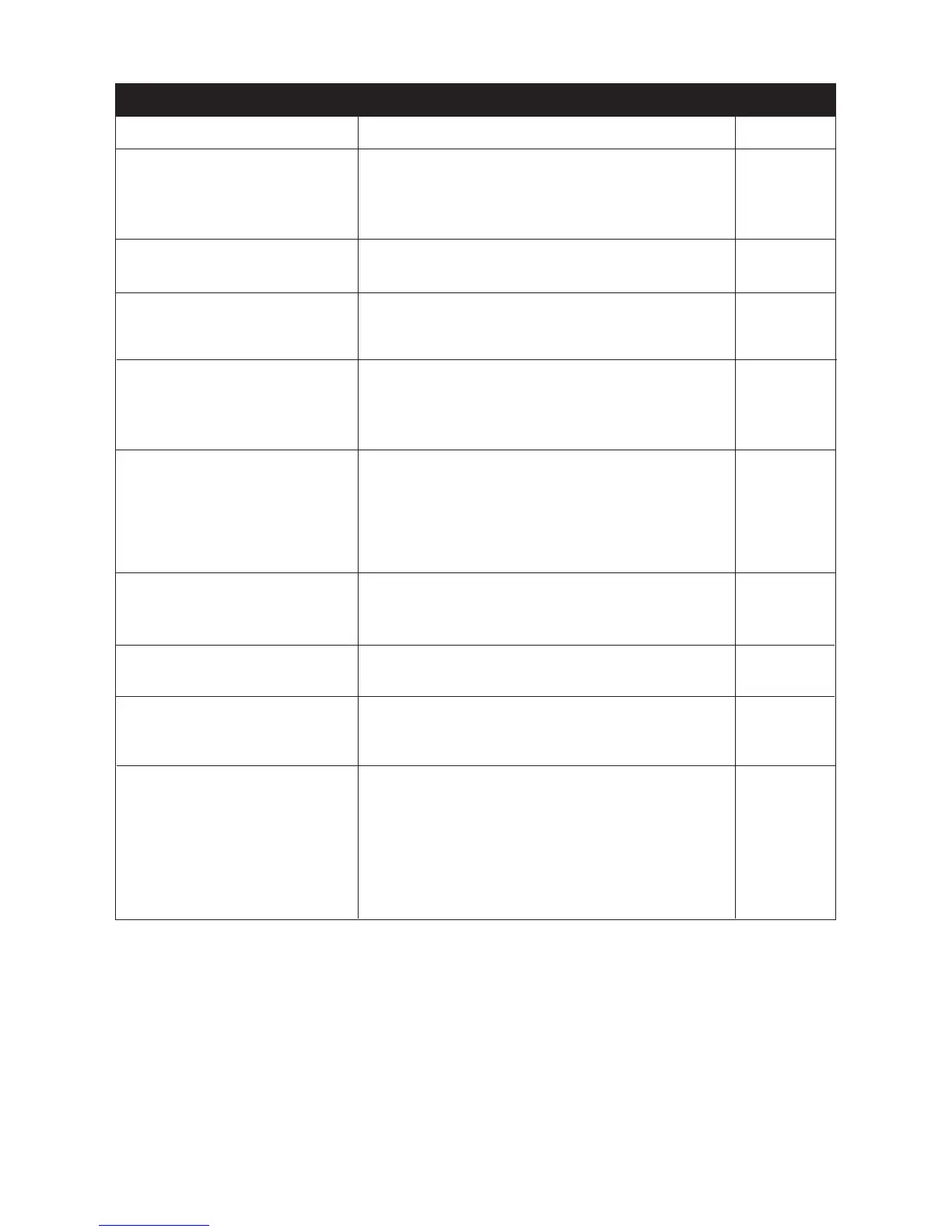

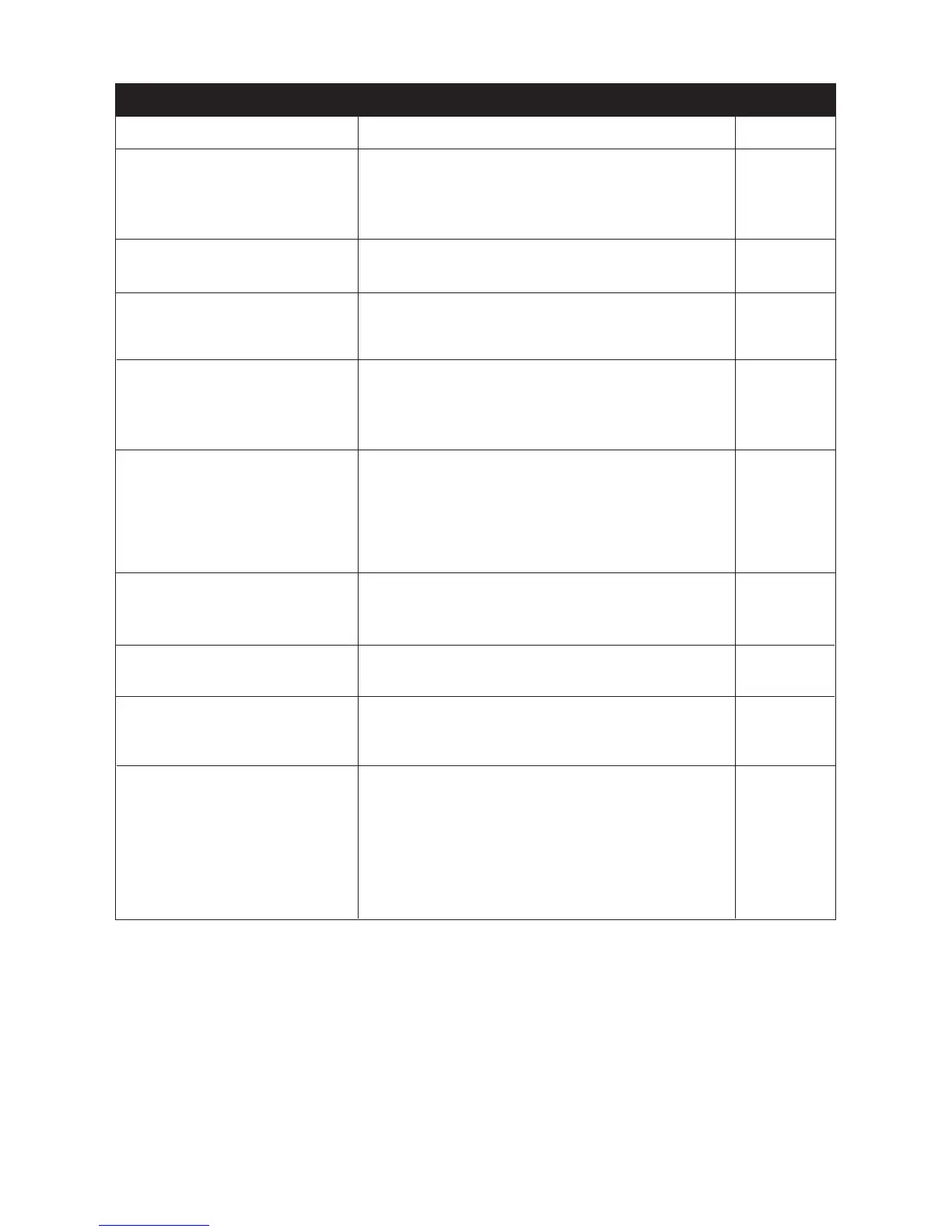

Water leakage - Machine left side.

Cause Action Ref.

1. Inlet valve scaled Inlet valve does not close properly due to scale and the 5A-7 / 5A-8

boiler overflows. Check replace inlet valve. Check also PL-3 / PL-10

the water hose for scale when the inlet valve is

replaced, as this scale may cause instant reoccurrence.

2. Tube between inlet valve Open left cover and check/correct. Always close left

and boilers queezed cover carefully in order not to squeeze/disconnect tube.

3. Machine has overboiled or Reset the machine. Unplug the power cord when

hot water has entered the before touching the reset switch.

overflow tube

4. Damaged boiler Check inlet of drain hose / inlet hose for small cracks.

Check connection between upper/lower part (welded).

Check front boiler leg for presence of cracks.

Replace boiler if necessary. 5A-1 / PL-4

5. Water level probe fault Check probe and its connections. Check if the GND 5A-5

(overflow) is connected.

Check boiler connector (24VDC) 5A-1(Illustr.)

Connect if necessary.

Heating element wiring not connected : no GND for

level probe pulse. Connect if necessary. PL-4

6. Boiler lid sealing not well Condensated water leaks through the sealing. Check 5A-5 / PL-4

the isolation at the side of the boiler opposite of the

frame for traces of water/scale.

7. Outlet valves not correctly Check / Correct.

installed

8. Outlet tubes not connected Check / Connect.

to nozzle

9. Boiler overflow (failing level Measure restistance between black (GND) wire of the SI038

detection due to poor power power board connector and the black (GND) at the back

board GND connection side of the board. If > 0 Ohm, replace power PCB.

If 0 Ohm, check Resistance between one of the black

(GND) wires and the lead (GND) in the middle of the

heating element plug. If >0 Ohm check

connections/wiring

Loading...

Loading...