9023744 - 3rd edition - October 2005

Page 17 of 40

Start-Up

Sensitivity Adjustment

Using commercially available test gas:

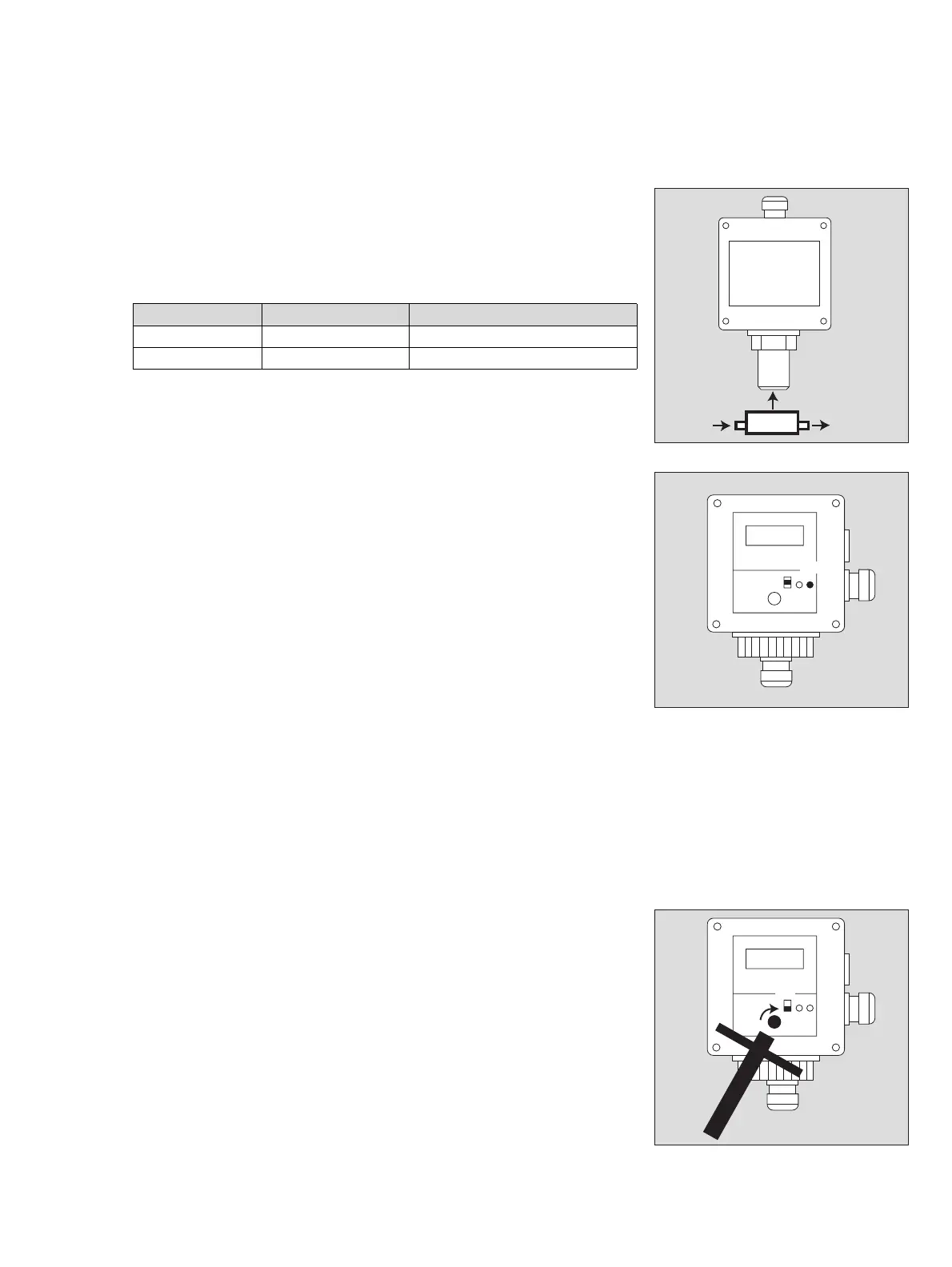

● Depending on the sensing head used supply the recommended calibration gas

concentration (s. table below) at a flow rate of approx. 0.5 L/min via the calibration

adapter.

Recommended concentrations:

— The calibration gas must be a mixture of the gas component to be monitored in

air. Mixtures with nitrogen are not suitable!

Once measured value display has stabilized (after max. 3 minutes):

1 Adjust sensitivity on potentiometer of the transmitter Polytron Ex R such that dis-

play indicates the calibration gas concentration.

When using the sensing head SE Ex LC M:

— The gas concentration is displayed without the decimal point, so the true concen-

tration is a tenth of the reading in % LEL.

— For calibration with solvent vapours, use can be made of the calibration chamber

(see Order List, page 31) in which a specified amount of solvent is evaporated, so

as to obtain, for example, 50 % LEL.

Adjustment is carried out as for calibration gas.

— The use of a calibration chamber requires appropriate training and knowledge on

the part of the operating personnel. Pay attention to usage instructions provided

with the calibration chamber!

If it is no longer possible to adjust sensitivity due to inadequate sensor sensitivity

(measured value to low),

or

if the measured value display does not stabilize after 3 minutes, the Ex-sensor must

be replaced (refer to page 22).

Following Completion of Calibration:

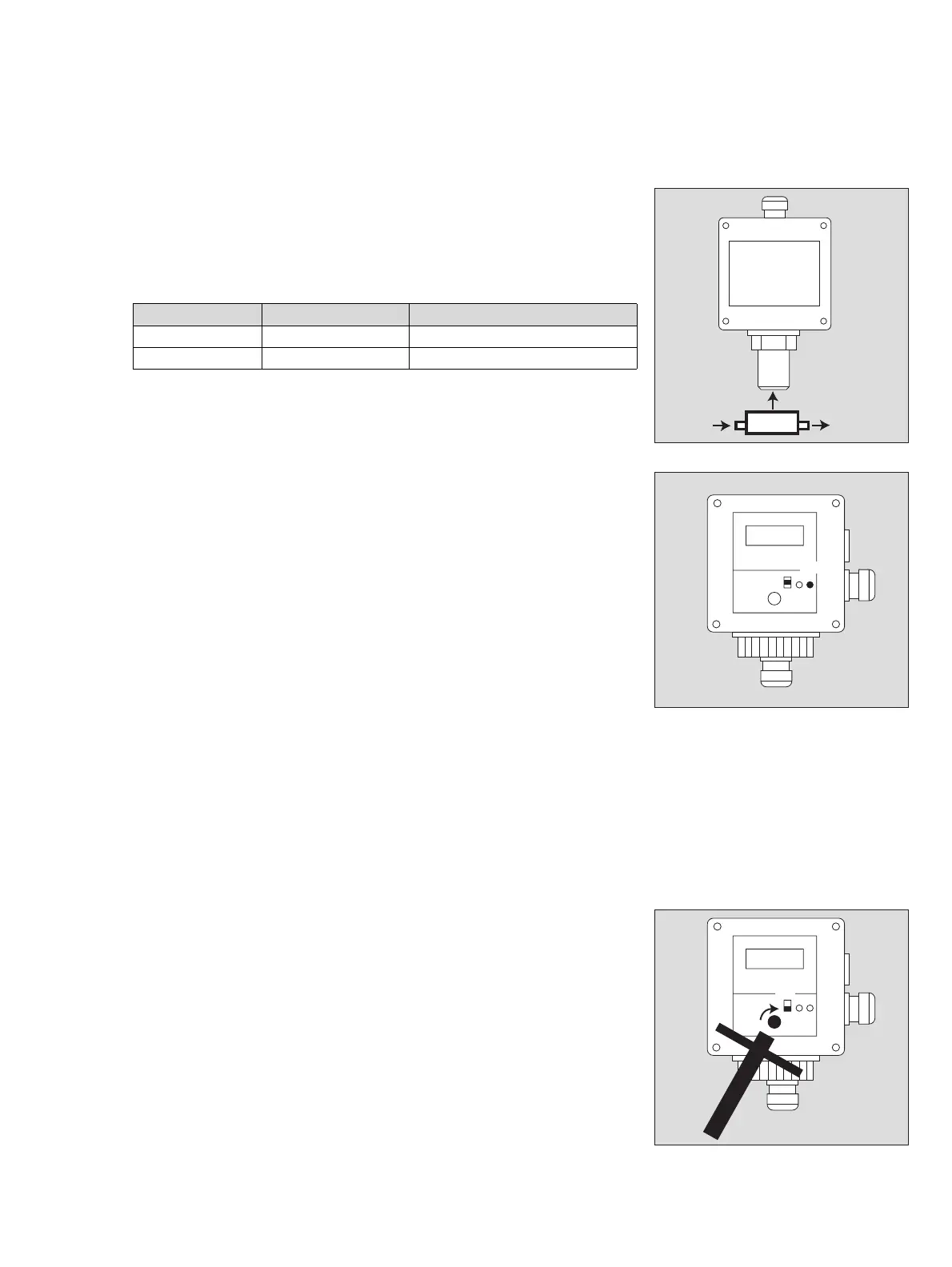

1 Set sliding switch to position »0« = normal.

2 Use special key to close flap in front of adjusters.

Sensing head Full scale value Calibration gas concentration

SE Ex PR M 100 % LEL 10 to 50 % LEL

SE Ex LC M 10 % LEL 3 to 7 % LEL

02623744_1_en.eps

Test gas

02323744_1.eps

1

02823744_1.eps

1

Loading...

Loading...