7 Installation, commissioning

80 D−LX 200, D−LX 720

7.6.1 Cable and screen

The Compact Flame Monitor D−LX 200, D−LX 720 is designed for switching

24 V⎓ voltages via the operation readiness contact and the flame contact. The

contacts can generate sparks when switching a load, which, in the case of

long line lengths, can affect other switching circuits.

It is advisable to install a junction box near the flame monitor and to execute

the subsequent cabling with separate, shielded lines.

Over short distances (< 5m) the lines are unsusceptible to interference and do

not need to be protected.

The single wires can be defined according to the system-specific

requirements. The cross-section for the 24 V⎓ supply line must be large

enough to ensure that R = 10 per wire is not exceeded. The D−LX 200,

D−LX 720 flame monitor will then still operate reliably at

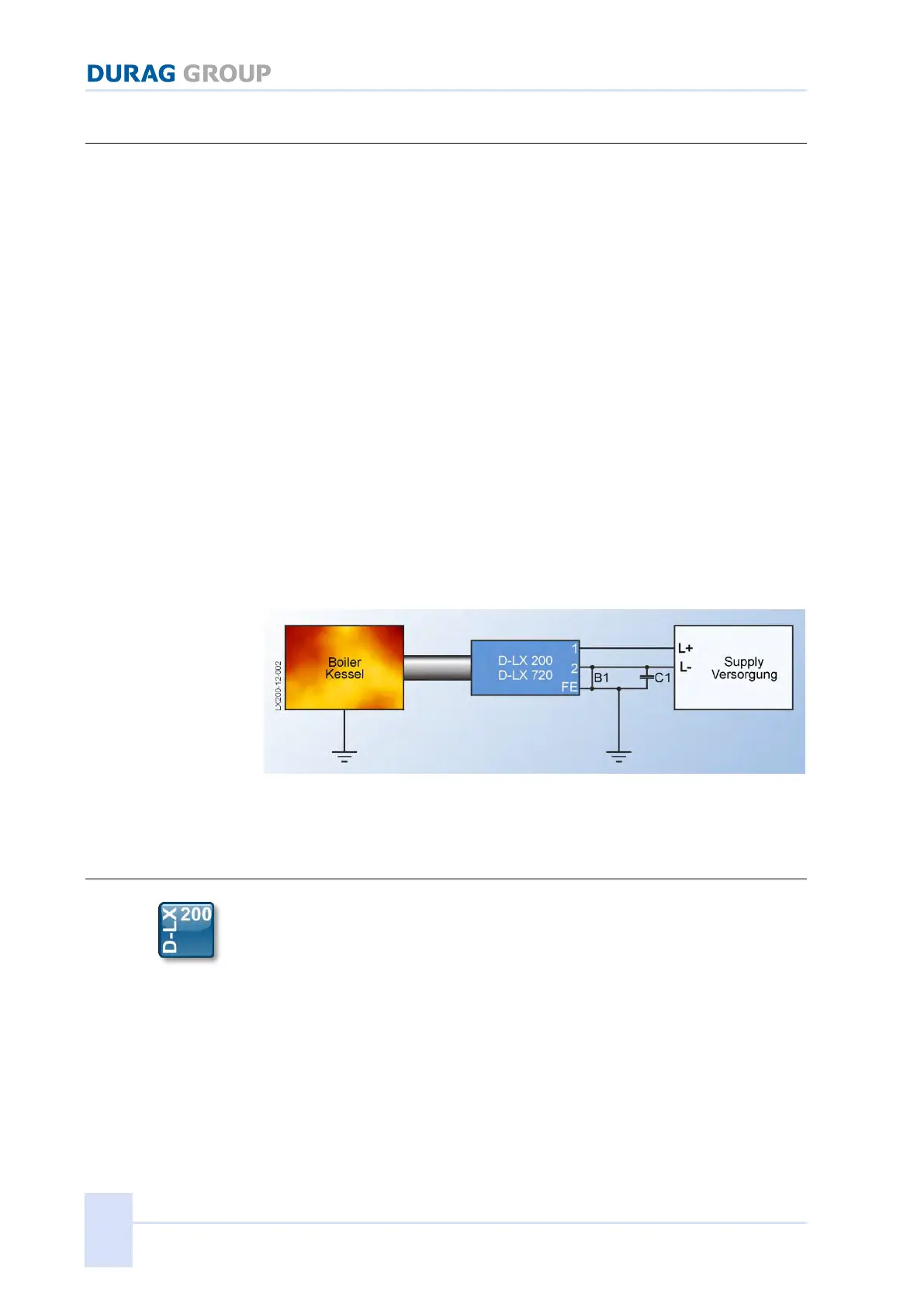

The D−LX 200, D−LX 720 has an electrically isolated design. There is no

connection between the 24 V⎓ supply voltage and the internal voltage of the

flame monitor. If faults occur after installation, the cause can be a ripple

voltage between the 0V potential of the supply and the internal operating

voltage.

This can be remedied with a capacitive coupling C1= approx. 100nF or by

eliminating the electrical isolation with a bridge B1.

Figure 7.15: Elimination of the potential separation

7.7 Installation, purge air supply

The purge air connection on the Compact Flame Monitor has the task of

keeping the sighting tube and the viewing glass clear of dirt from the

combustion chamber. This is done by maintaining a flow of air towards the

combustion chamber, which carries away even heavier particles. For

combustion systems with low particle levels such as gas-firing, an air speed of

v=1 m/s in a 1¼" sighting tube gives sufficient purging (air consumption

approx. 3m³/h). On the other hand, for combustion systems with particle levels

such as coal firing, greater purge air quantities are required (air speed

v=3 m/s) to keep them clean. The speed of the purge air in the sighting tube is

only an indicative value and must be determined specifically for each system.

A ½" internal screwed connection is provided for the purge air on the flame monitor.

The flame monitor should be checked regularly to ensure that the optics are

clean and securely seated in the front part.

If flame monitors must be mounted to sighting tubes with high temperature

exposure, the purge air also serves as coolant. In such cases it is

Loading...

Loading...