Parameters

110 M-Max Series Adjustable Frequency Drive MN04020003E—October 2013 www.eaton.com

On the constant three-phase AC supply, the three-phase

asynchronous motor has a constant rotor speed (n

1

, P7.3,

rating plate specifications) according to the number of pole

pairs and input frequency. The slip here represents the

difference between the rotating field of the stator and that of

the rotor. In static operation, the slip is constant.

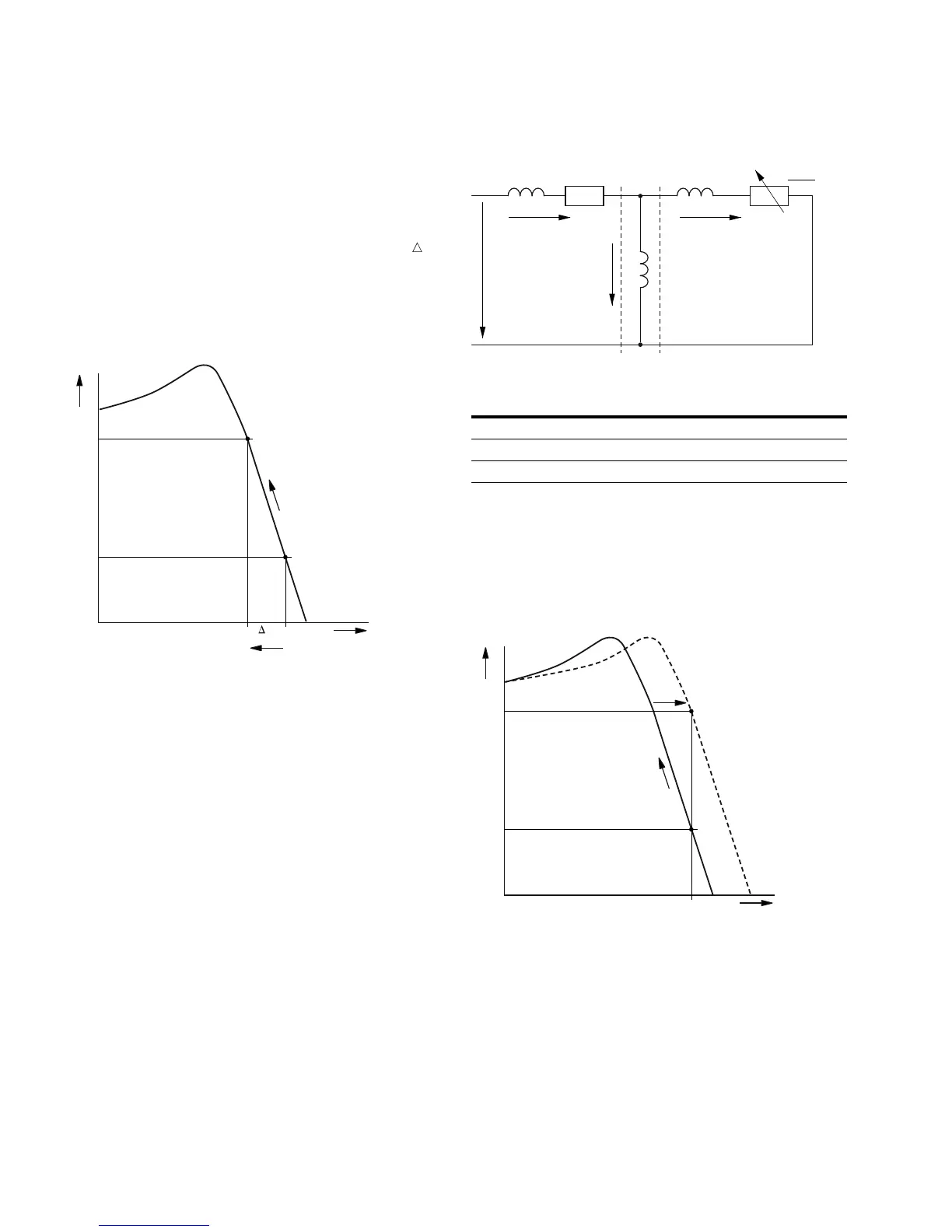

Load changes [1] at the motor shaft cause a larger slip ( n)

and thus a reduced rotor speed [2]. In controlled operation

(V/f-characteristic), the frequency inverter cannot

compensate this load-related speed difference. The speed

behavior of the motor is even, as in a constant AC supply.

Speed Behavior without Slip Compensation

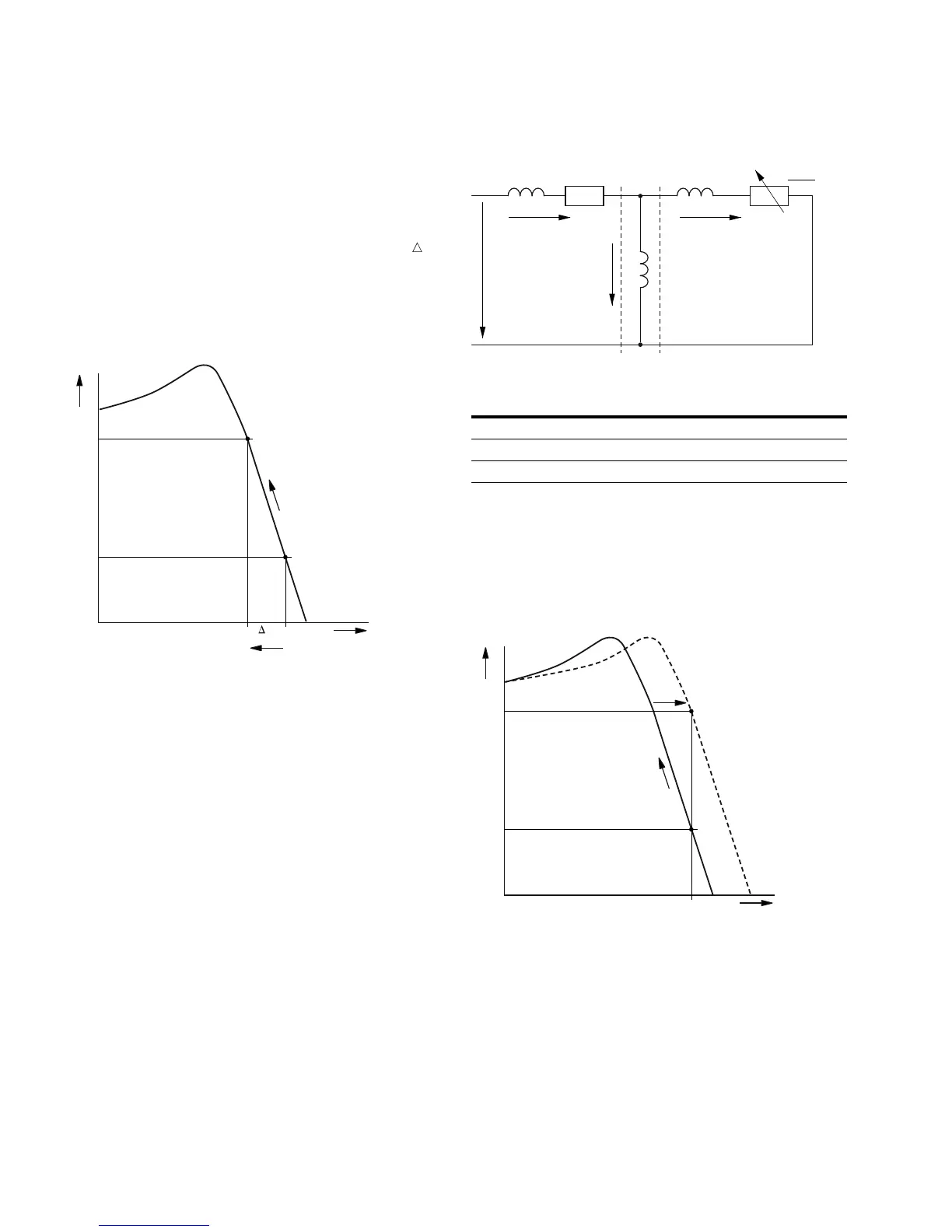

In “Speed control” mode (P11.8 = 1), the frequency inverter

can compensate these load-related deviations. From the

measured voltage and current values of the stator winding

(u

1

, i

1

) the internal motor model calculates the required

manipulated variables for the flux variable i

μ

and the torque

variable i

w

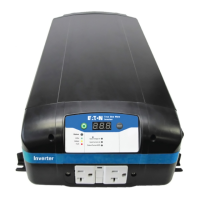

. In the equivalent circuit diagram of the

three-phase motor, the load-related slip is shown as the

resistance R’

2

/s. In idle operation without a load, this

resistance approaches infinity, and approaches zero as the

load increases.

Equivalent Circuit Diagram for an Asynchronous Motor

An exact calculation requires the precise rating specifications

of the motor (parameter group 7). The speed control (P11.8 =

1) can then compensate the load-related slip deviations. The

simple illustration shows that, as the load torque increases

[1], the resulting speed reduction is compensated by an

increase in the output frequency

[2] (see figure below).

Speed Behavior with Slip Compensation

n

M

M

2

M

1

n

1

n

2

n

1

2

Item

Number Description

1 Stator winding

2 Air gap

3 Transformed rotor winding

R

1

X'

2

X

1

i

1

i

w

u

1

X

h

i

m

123

R'

2

s

M

M

2

M

1

n

1

n

1

2

Loading...

Loading...