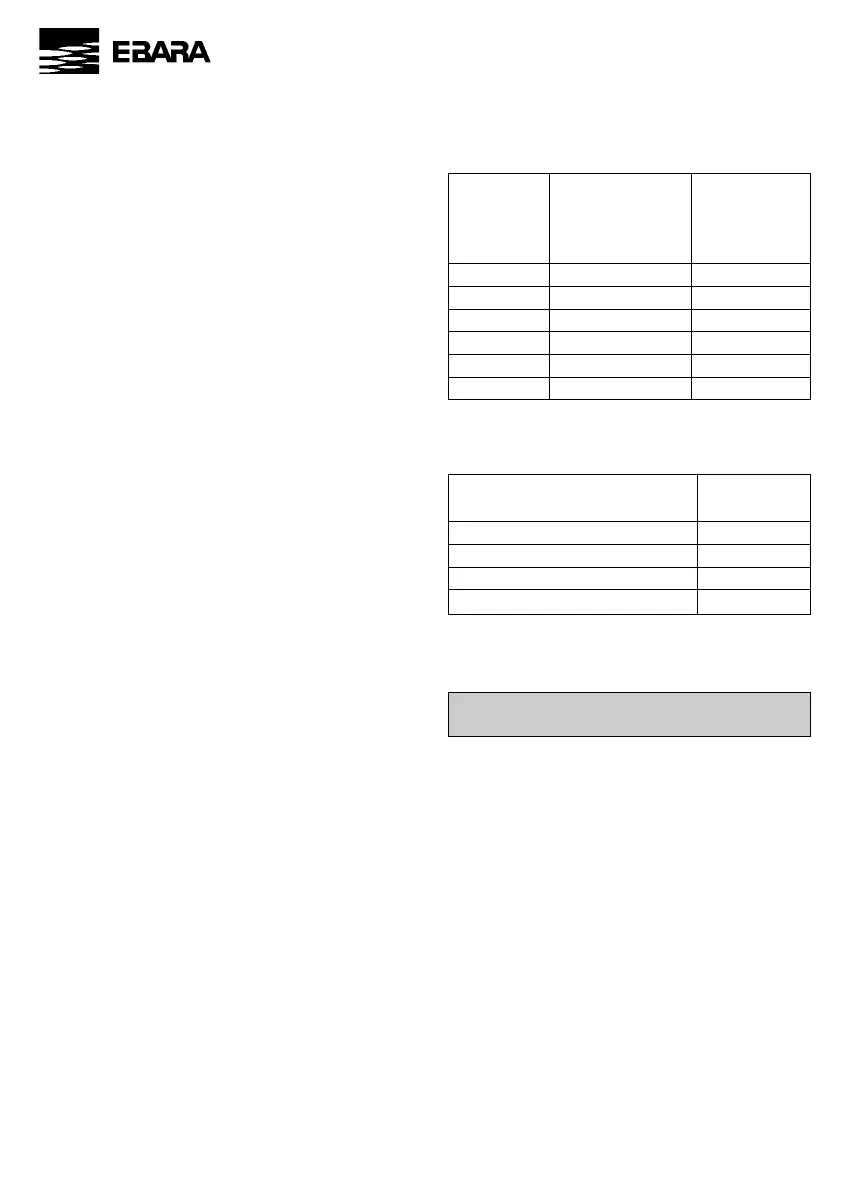

TAB.1: Classification of the maximum surface tem-

perature for apparatuses belonging to group II G (in

accordance with the EN 13463-1 norm)

Temperature Maximum pump Gas or vapour

classification surface mix

temperature ignition

(C°) temperature (°C)

T1 450 >450

T2 300 >300

T3 200 >200

T4 135 >135

T5 100 >100

T6 85 >85

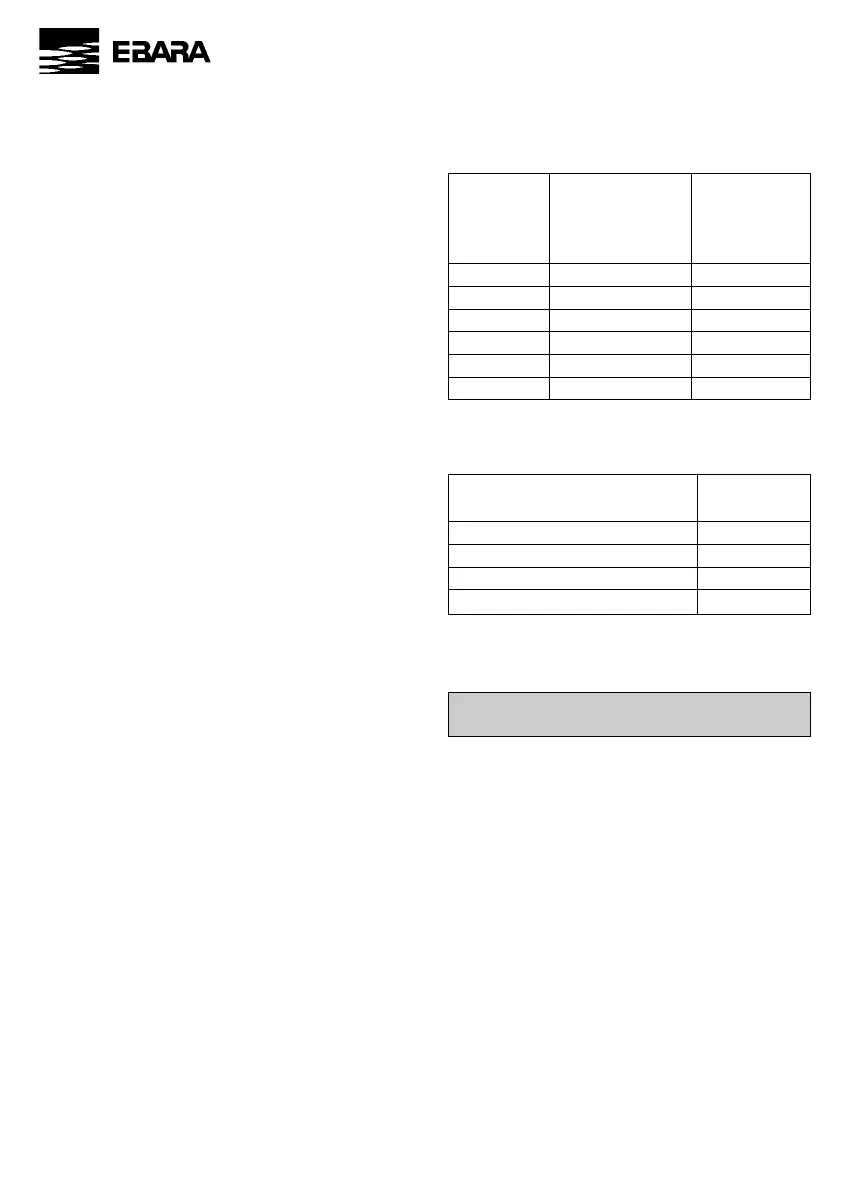

TAB. 2: Maximum temperature of the fluid in accor-

dance with the temperature classification

Maximum temperature of the fluid Temperature

[°C] classification

120 *) T1

120 *) T2

120 *) T3

80 T4

*) Technical datum given in paragraph 7.1 of the

User and Maintenance Manual of the EVM product.

Please refer to paragraph of the instruction booklet

for information on maintenance and repairs.

In addition, the pump must never be cleaned using

dry cloths (rubbing with dry cloths made of pure

polyamide material or cotton, for example, can cau-

se electric discharges).

Some EVM pump models have a bearing on the joint.

No maintenance needs to be carried out on the bea-

rings, which should work for 10,000 hours at a tem-

perature of 40°C without problems.

When replacing or controlling the bearings, the user

must contact the retailer or the help service. The sa-

me is true for the seal (para. 7.2).

Verify, proportionally to the operation conditions,

that the compression ratio is lower than the sponta-

neous ignition limit of the processed fluid.

Correct motor alignment is indispensable for preven-

ting vibrations and faulty bearings.

10 – EVM

Correct assembly of the fluid monitoring device insi-

de the pump ensures that the seal is always lubrica-

ted by the fluid during operation.

Under these conditions, the seal is guaranteed for

continuous 24-hour operation for 6 months.

When replacing or controlling the seal, please refer

to the retailer or the help service.

7.3. PUMP OPERATION WITH AN OBSTRUC-

TED/CLOSED DELIVERY VALVE

FIGURE 5 shows the assembly drawing of the flow

rate measurer (Mp) which must be assembled at de-

livery so that the pump (P) blocks when the flow ra-

te falls below 5% of the maximum return point. In

this case the electric contact (C) deactivates/activa-

tes, disconnecting the electric power supply and ren-

dering the pump safe.

This value guarantees respect of temperature classi-

fication on the internal and external surfaces of the

pump.

7.4. DAMAGE CAUSED BY CHEMICAL NON COM-

PATIBILITY BETWEEN LIQUID AND COMPO-

NENTS

Check the chemical compatibility between the fluid

and the pump parts.

7.5. CAVITATION

It is important to always check correct pump sizing

(therefore it is essential to verify the value needed by

the pump using the NPSH curves. These curves can

be found in the product general catalogues).

7.6. HOT FLUIDS

TAB. 2 gives the maximum temperature that the fluid

can reach in each temperature classification (these

values are permitted respecting the conditions ex-

pressed in point 5.3 NOTES).

It is important to install a reading device in order to

guarantee the maximum temperature of the fluid.

Should the limit value indicated in TAB. 2 be excee-

ded, a release apparatus should switch the pump off.

The temperature measuring instrument must be in

conformity with the UNI EN 13463-1 norm (category

4 of the Machines Directive) and carry an ATEX

marking that is compatible with that of the pump.

The switchboard which guarantees intervention

when the limit values are exceeded must be FAILU-

RE SAFE.

8. MAINTENACE AND REPAIRS

Loading...

Loading...