WARNING: For a correct working of the pump, verify what follows:

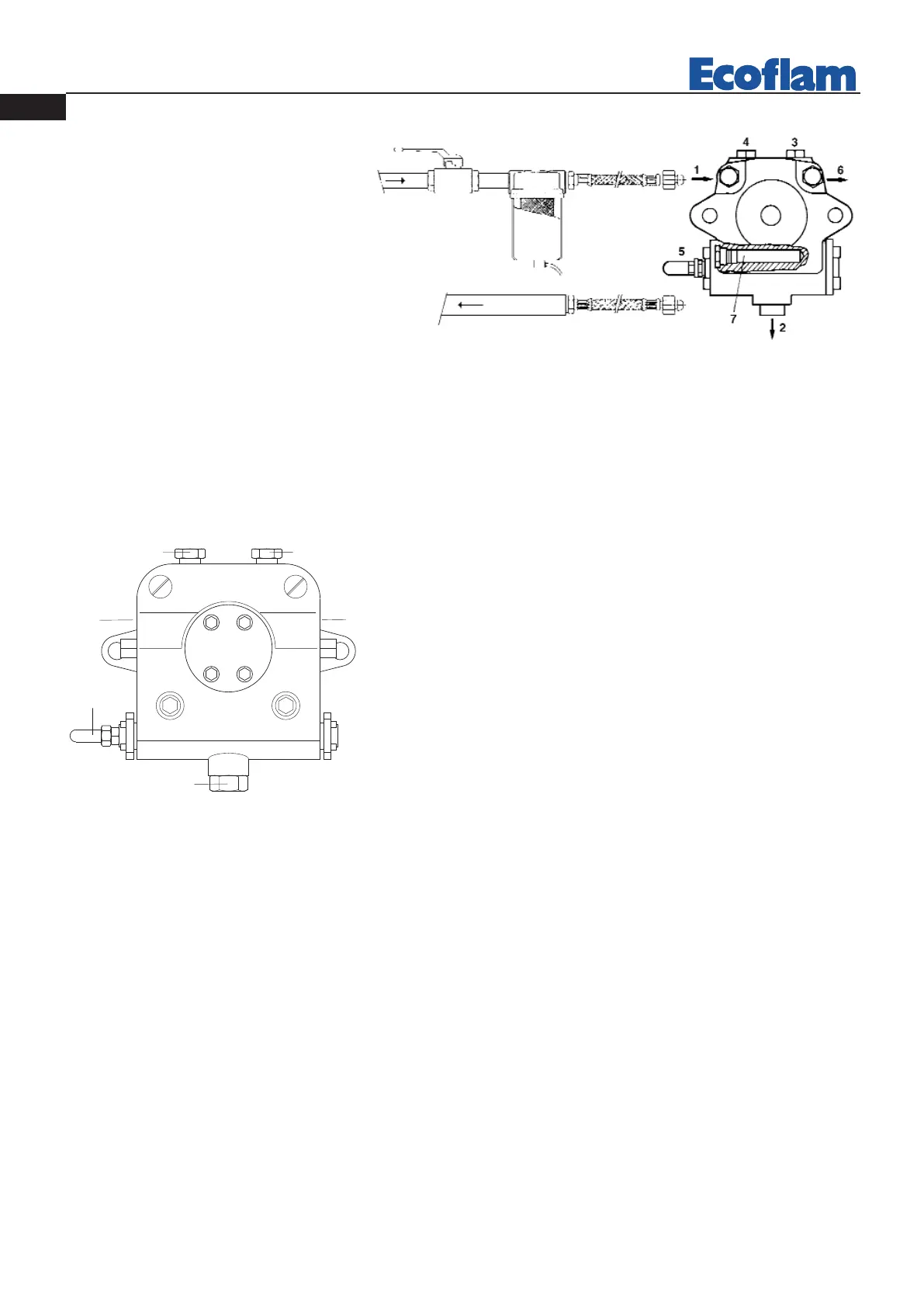

Pump : SUNTEC TA...C40105

Oil temperature at the pump: Max. 140 °C

Maximum allowable pressures: Max. 5 bar on inlet

SUNTEC TA2C4

PRIMING AND ADJUSTMENT OF OIL PUMP

1 - INLET

2 - RETURN

3 - BLEED AND PRESSURE GAUGE PORT

4 - VACUUM GAUGE PORT

5 - PRESSURE ADJUSTMENT

6 - TO NOZZLE

VERIFY:

- That piping system is perfectly sealed;

- That the use of hoses is avoided whenever is possible (use copper pipes preferably);

- That depression is not greater than 0,45 bar, to avoid pump’s cavitation;

- That check valve is suitably designed for the duty;

The pump pressure is set at a value of 22-25 bar during the testing of burners. Before starting the burner, bleed the air

in the pump through the gauge port. Fill the piping with light-oil to facilitate the pump priming. Start the burner and

check the pump feeding pressure. In case the pump priming does not take place during the first prepurging, with a con-

sequent, subsequent lock-out of the burner, rearm the burner’s lock-out to restart, by pushing the button on the control

box. If, after a successful pump priming, the burner locks-out after the prepurging, due to a fuel pressure drop in the

pump, rearm the burner’s lock-out to restart the burner. Do never allow the pump working without oil for more than

three minutes.

Note: before starting the burner, check that the return pipe is open. An eventual obstruction could damage the

pump sealing device.

EN

420010310200 MULTICALOR 300.1-400.1 PR/PR

22

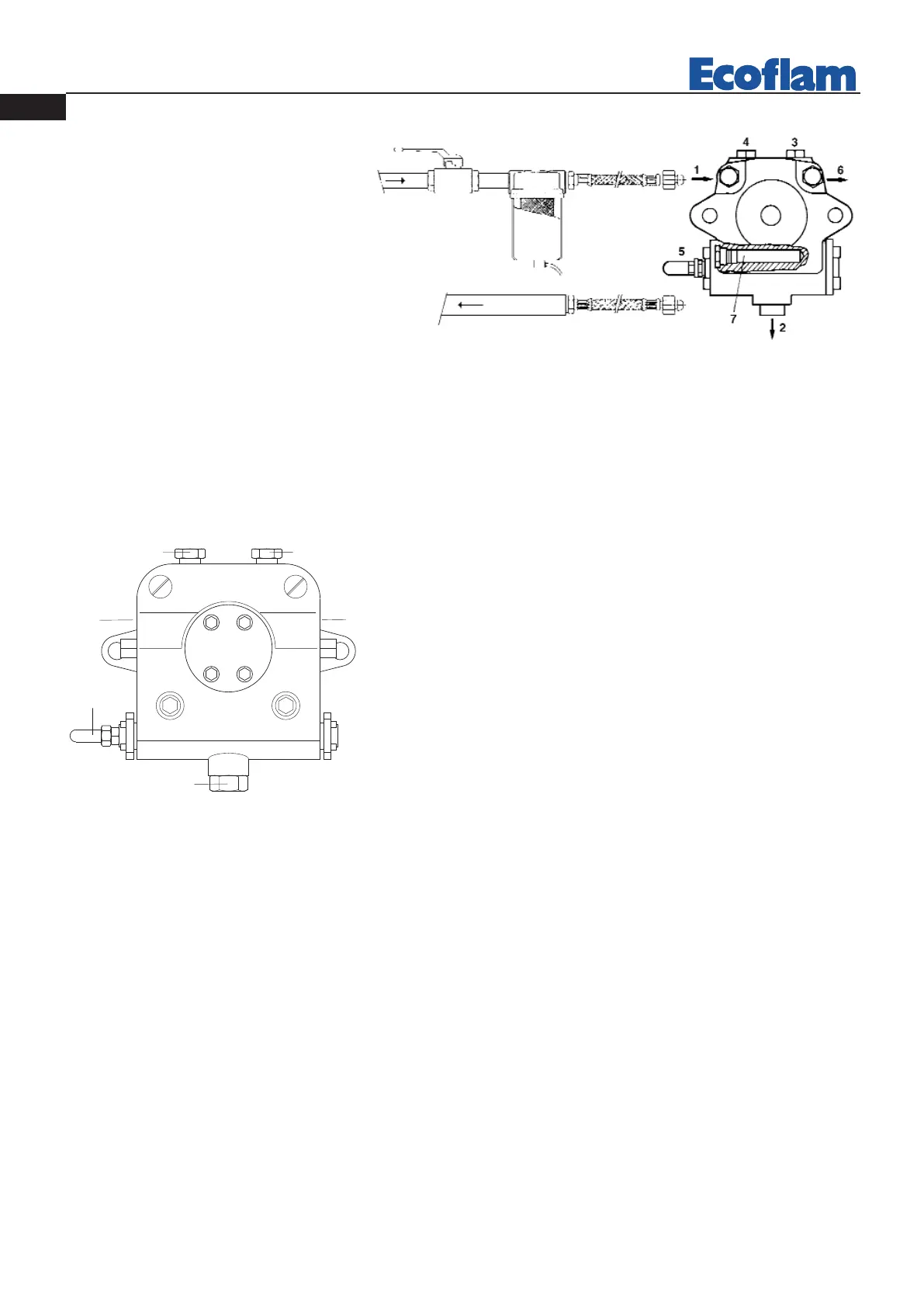

LIGHT OIL FEEDING

1 - Inlet

2 - Return

3 - Bleed and pressure gauge port

4 - Vacuum gauge port

5 - Pressure adjustment

6 - Nozzle outlet

7- Heater

230V 50Hz

Loading...

Loading...