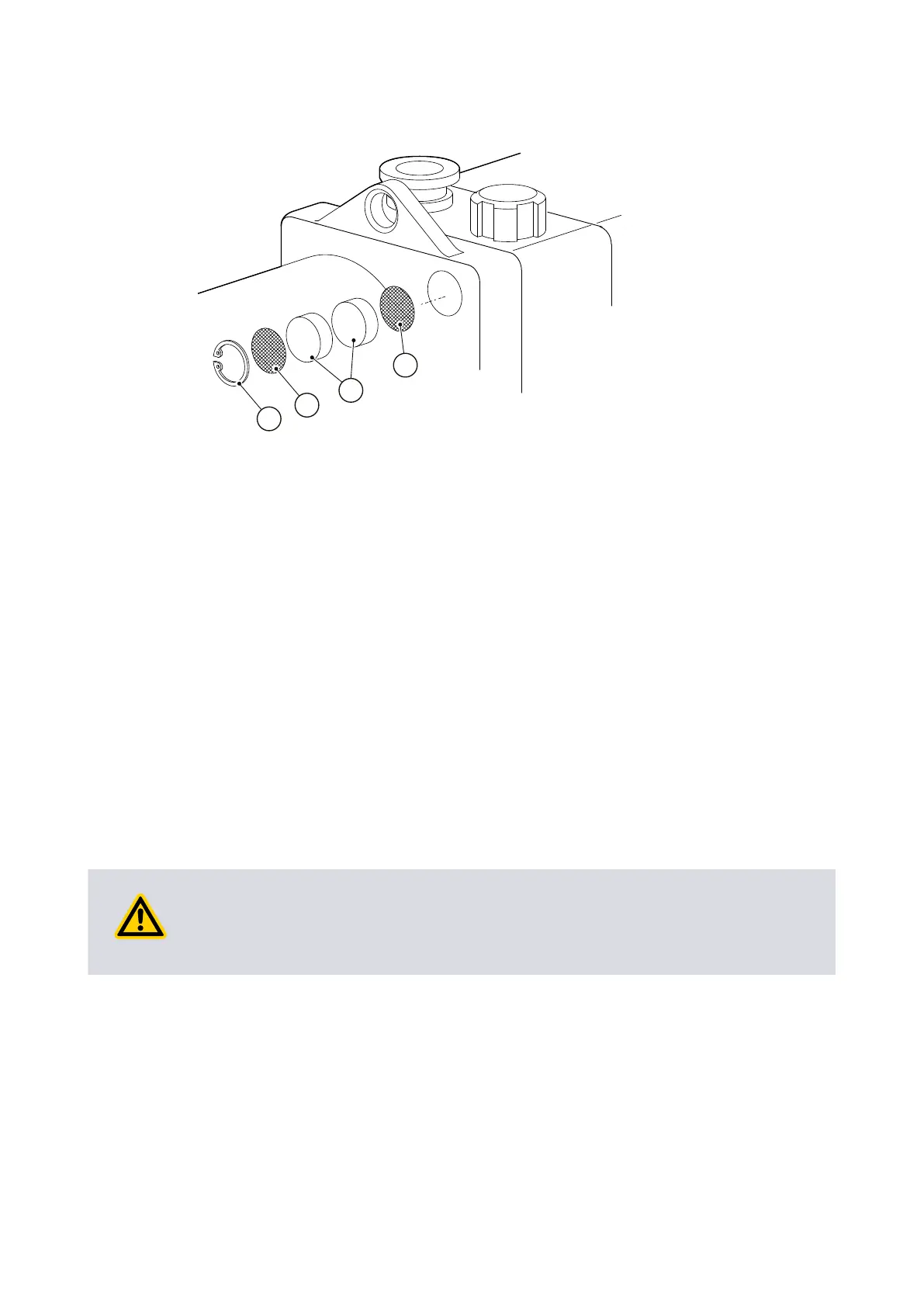

Figure 10 Remove/replace the gas-ballast lter

1. Filter element 2. Wire mesh

3. Retainer circlip

1. Filter element 2. Wire mesh

3. Retainer circlip

6.7 Clean the motor fan-cover and enclosure

If the motor fan-cover and enclosure are not kept clean, the air ow over the motor can

be restricted and the pump may overheat.

1. Switch o the pump and disconnect it from the electrical supply.

2. Use a dry cloth and a brush to remove dirt and deposits from the fan-cover and

enclosure.

6.8 Clean and overhaul the pump

Clean and overhaul the pump as described in the instrucons supplied with the clean

and overhaul kit (see Spares and accessories on page 43).

6.9 Replace the run capacitor and test the motor

WARNING:

Change the run capacitor as per the maintenance plan.

Replace the run capacitor as described in the instrucons supplied with the capacitor kit.

Refer to Table: Capacitor kits on page 43, Spares on page 43.

Test the earth (ground) connuity and the insulaon resistance of the pump-motor, in

accordance with local regulaons for periodic tesng of electrical equipment. We

recommends that:

▪

The earth (ground) connuity is less than 0.1 W.

▪

Insulaon resistance is greater than 10 MW.

If the motor fails these tests, replace the motor.

Page 37

A37310880_V - Maintenance

Loading...

Loading...