© Edwards Limited 2008. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

B753-03-880 Issue F

2.6 Materials exposed to gases pumped

The following materials and component types are exposed to the gases pumped: aluminium alloys, stainless steels,

fluoroelastomer and nitrile 'O' rings, hydrocarbon lubricant, felt, rare earth magnets, silicon nitride, phenolic resin

and carbon-fibre reinforced epoxy resin.

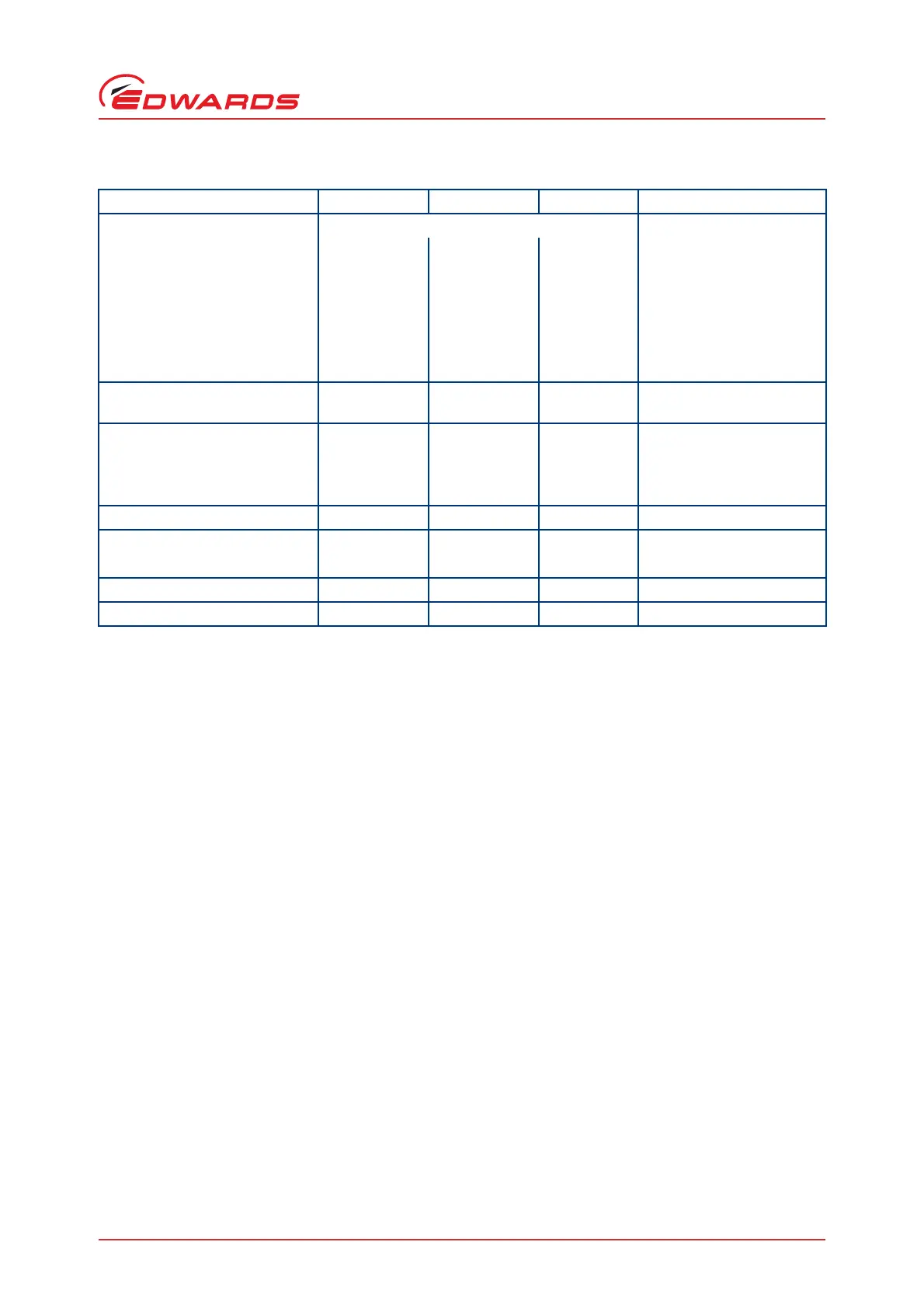

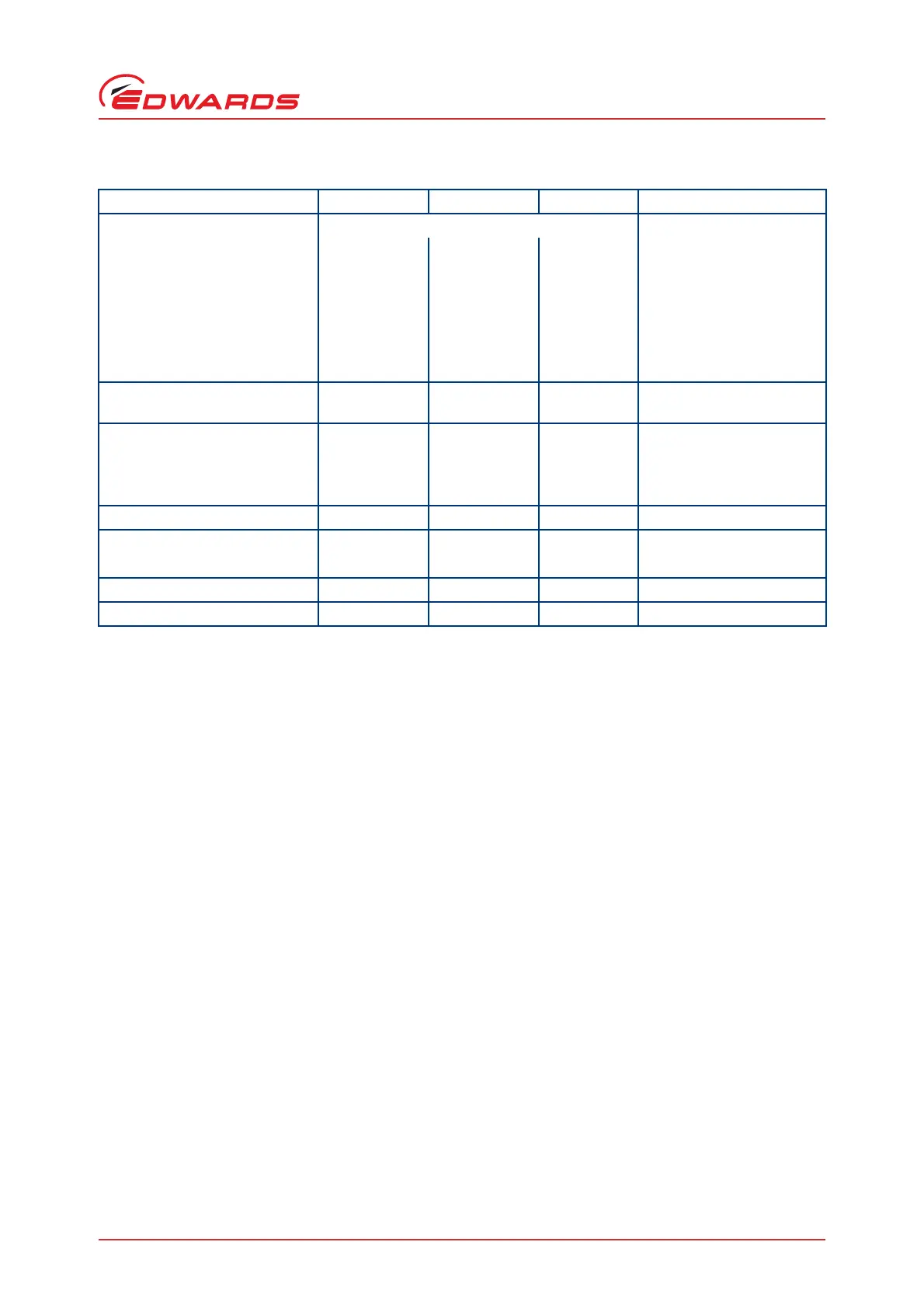

Operating attitude Vertical and upright through to horizontal

±2°

Nominal rotational speed 60000 r min

-1

60000 r min

-1

60000 r min

-1

Standby rotational speed 42000 r min

-1

42000 r min

-1

42000 r min

-1

Starting time to 90% speed

EXC100E 190 sec 190 sec 190 sec

EXC120 130 sec 130 sec 130 sec

EXC300 100 sec 100 sec 100 sec

Cooling method Forced-air/

water

Forced-air/

water

Forced-air/

water

Ambient air temperature

(forced-air cooling)

0 - 35 °C 0 - 35 °C 0 - 35 °C

Water temperature

(water-cooling)

10 - 20 °C 10 - 20 °C 10 - 20 °C

Noise level (at 1 metre) < 50 dB(A) < 50 dB(A) < 50 dB(A)

Recommended controller EXC120 EXC120 EXC120

EXC120 maximum VA input 250 VA 250 VA 250 VA with bakeout band

Quiescent power 25W 25W 25W

Recommended backing pump

†††

RV3 RV3 RV3

*

Not supplied - pump supplied with port blanked.

†

Pb = backing pressure, Qi = flow through the interstage-port (EXT255Hi/EXT255HVi only), Qp = flow through

pump-inlet.

‡

Pumping speeds are without inlet-screen or inlet-strainer (EXT255Hi/EXT255HVi only). Inlet-screens and

inlet-strainers reduce speed by approximately 10%.

**

Ultimate pressure 48 hours after bakeout with Pb < 1 x 10

-2

mbar (1 Pa).

††

Ultimate pressure 48 hours after bakeout with Pb < 5 mbar (500 Pa).

‡‡

Inlet pressure has risen to 1 x 10

-3

mbar (1 x 10

-1

Pa).

***

Above this pressure, rotational speed drops below nominal.

†††

A larger backing pump may be required for maximum throughput.

Table 1 - Technical data (continued)

Parameter EXT255H EXT255Hi EXT255HVi Notes

Loading...

Loading...