© Edwards Limited 2012. All rights reserved. Page 37

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

A705-61-880 Issue M

5. Fit the new interstage relief valve to the exhaust manifold and secure with the four M8 bolts (11). Tighten the

bolts to a torque of 10 Nm (7.4 lbf ft).

5.11 Replace the Pump-Motor

Note: If you have supplied your own pump - motor you are responsible for its maintenance which must be carried

out in accordance with the motor manufacturer’s recommendations. If the motor is a Edwards supplied

product, please consult the supplied literature or contact Edwards for further information.

5.11.1 Remove the Pump-Motor

Use the following procedure to remove the pump-motor. Ensure that the pump-motor is adequately supported

throughout and does not fall.

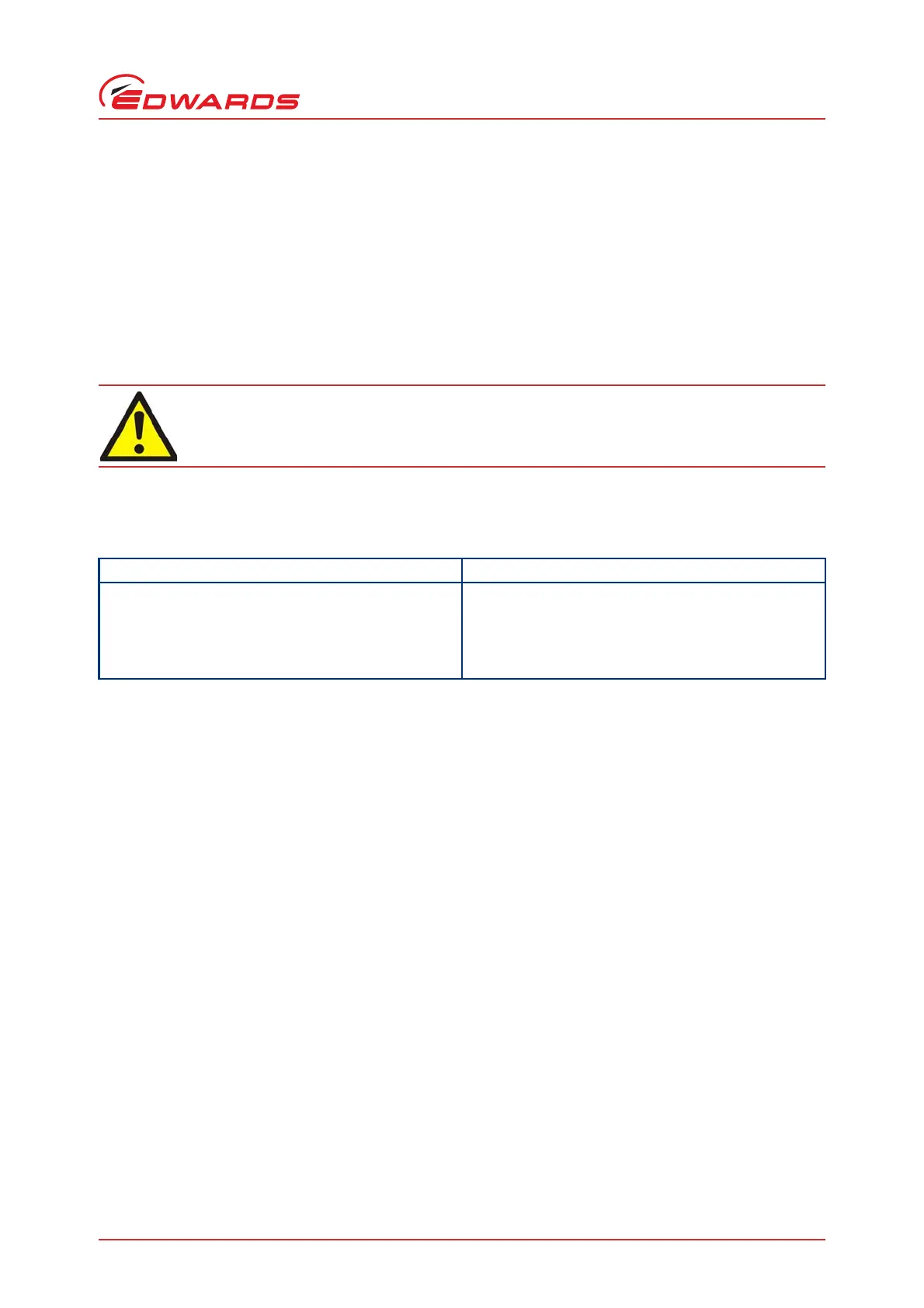

The masses of the pump-motors are as shown below:

1. Refer to Figure 1. Remove the cover from the pump-motor terminal - box (17) and disconnect your electrical

supply cable from the terminal-box.

2. Refer to Figure 10. Fit slings and suitable lifting equipment to support the pump-motor, then remove the fixing

bolts (1) which secure the pump-motor (19) to the coupling housing (7).

3. Use the lifting equipment to move the pump-motor (19) away from the pump, then carefully lower the pump-

motor, so that it rests on the floor in an upright orientation (that is, with the drive hub (16) at the top).

4. Undo the set screws (3) on the holding ring (17), then remove the holding ring.

5. Remove the coupling insert (15) and inspect it; if necessary, replace it.

6. Undo and remove the set screw (4) in the drive hub (16).

7. Use a suitable puller tool to remove the drive hub (16) from the motor shaft (18), then remove the key (2) from

the motor shaft. Dispose of the key.

8. Dispose of the pump-motor: refer to Section 6.2.

Ensure that the pump-motor cannot fall when you remove it. The pump-motor is heavy and can

cause injury to people if it falls.

Pump/electrical supply Motor mass

GV250: 380/400/415 V, 50 Hz 104 kg

GV250: 230/460 V, 60 Hz 286 lbs

GV400: 380/400/415 V, 50 Hz 126 kg

GV400: 230/460 V, 60 Hz 364 lbs

Loading...

Loading...