A705-61-880 Issue M

Page 42 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

5.13.2 Relubrication intervals

The required interval between motor bearing relubrication depends on a number of factors, such as ambient

temperature and so on. To determine the required intervals between relubrication:

Refer to Table 15 which provides general guidelines on the required interval between relubrication.

Refer also to the nameplate on the motor for relubrication intervals and grease quantities specific to

that motor.

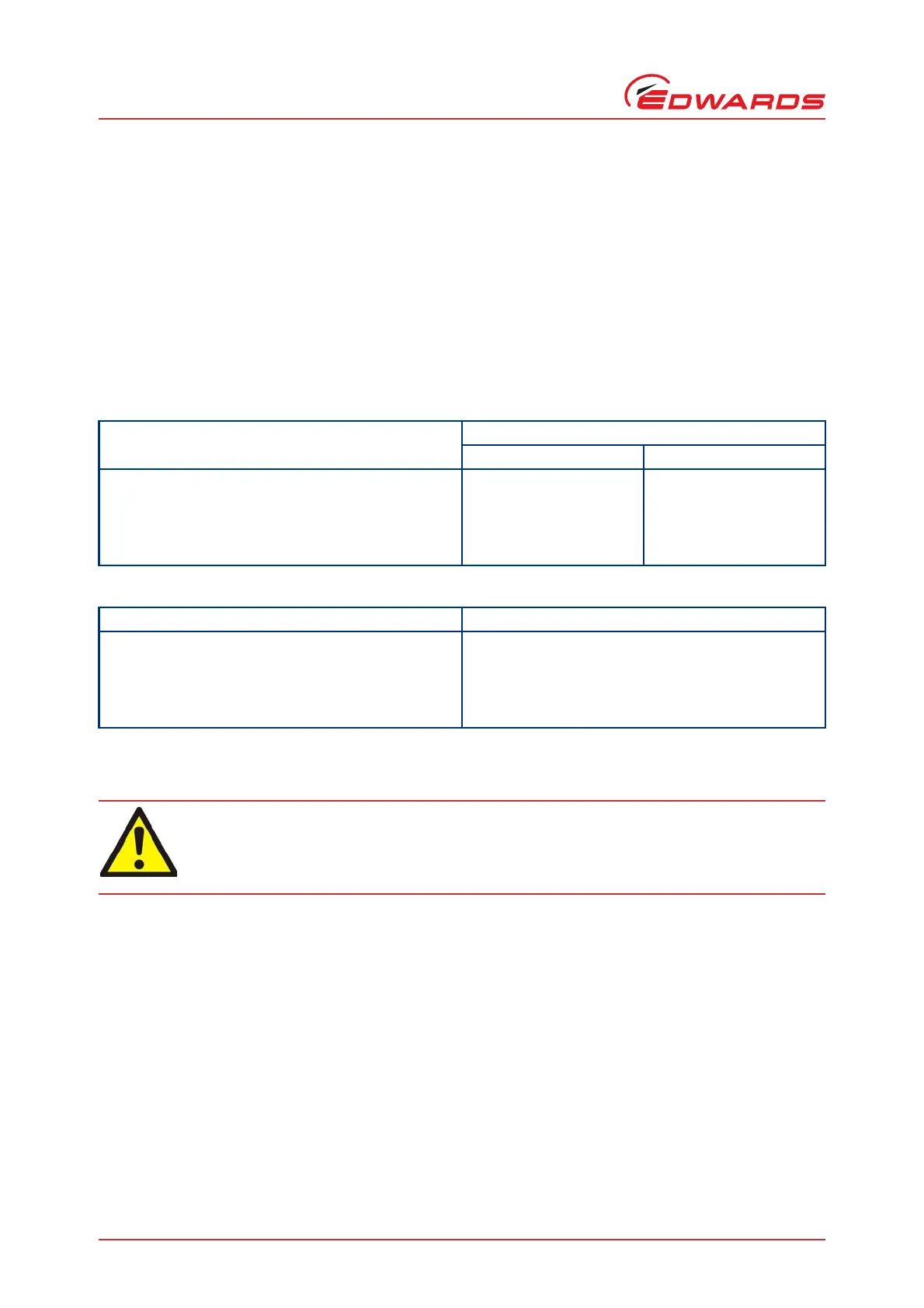

Note: The data given in Table 15 is for an ambient temperature of 25 °C (77 °F). If the pump is operated in an

ambient temperature of 40 °C (104 °F), the required relubrication intervals will be 50% of those shown

in the table.

5.14 Replace the motor bearings

You must only replace the motor bearings if you have been suitably trained in all the procedures required to

dismantle and reassemble the motor, and to replace the bearings.

Take note of the following when you replace the motor bearings:

You will need a Motor bearing kit: refer to Section 7.3.

Use the procedures in this manual to remove and refit the motor.

Only use approved procedures to dismantle and reassemble the motor, and to replace the bearings.

5.15 Overhaul the pump

We recommend that the pump is given a major overhaul every three years. Such an overhaul is outside the scope of

this manual and should be done by qualified Edwards service personnel: contact your supplier or Edwards.

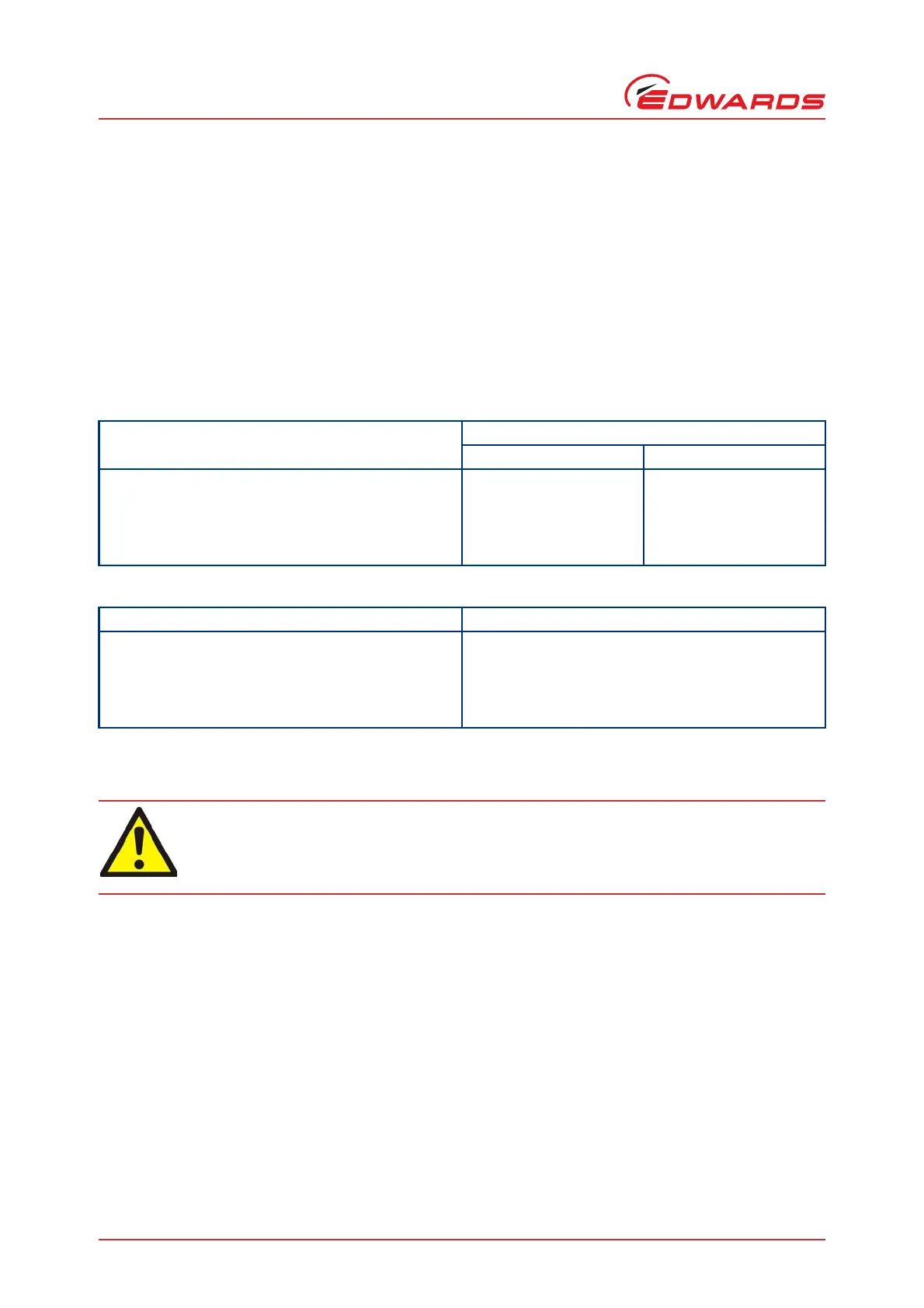

Table 14 - Motor relubrication grease required

Pump

Quantity of grease required

Non-drive end bearing Drive end bearing

GV250, 380/400/415 V, 50 Hz 12 c.c. 12 c.c.

GV250, 230/460 V, 60 Hz 0.2 fluid oz 0.6 fluid oz

GV400, 380/400/415 V, 50 Hz 12 c.c. 12 c.c.

GV400, 230/460 V, 60 Hz 0.4 fluid oz 0.6 fluid oz

Table 15 - Motor bearing relubrication intervals

Pump Relubrication interval (hours of operation)

GV250, 380/400/415 V, 50 Hz 7200

GV250, 230/460 V, 60 Hz 4400

GV400, 380/400/415 V, 50 Hz 7200

GV400, 230/460 V, 60 Hz 4400

Do not replace the motor bearings unless you have been suitably trained in the necessary

procedures. If you are not suitably trained, you may damage the motor and it may not operate

correctly or safely.

Loading...

Loading...