© Edwards Limited 2007. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Serial Interface Operation

D374-20-880 Issue E

5.5 Simulation Mode

5.5.1 Introduction

Note: When the iTIM is first switched on, it automatically enters the normal mode.

The serial interface card can operate in one of two modes:

1. In normal mode, query and command messages are associated with the dry pumping system to which the serial

interface card is connected, as described in Section 5.3 and 5.4.

2. In simulation mode, query and command messages can be sent to the serial interface card as in normal mode,

but are associated with a ‘simulated pumping system’ in the serial interface card. In this mode, command

messages do not affect the dry pumping system and replies to query messages contain information about the

simulated pumping system, not the dry pumping system.

Use the simulation mode command message (refer to Section 5.4.6) to enter and exit the simulation mode.

Note: The serial interface card maintains a common store data associated with the actual or associated dry

pumping system. When you exit the simulation mode, this store is cleared, it may the take up to 45 seconds

for the serial interface card to acquire the new data from the actual dry pumping system.

5.5.2 Simulated pumping system

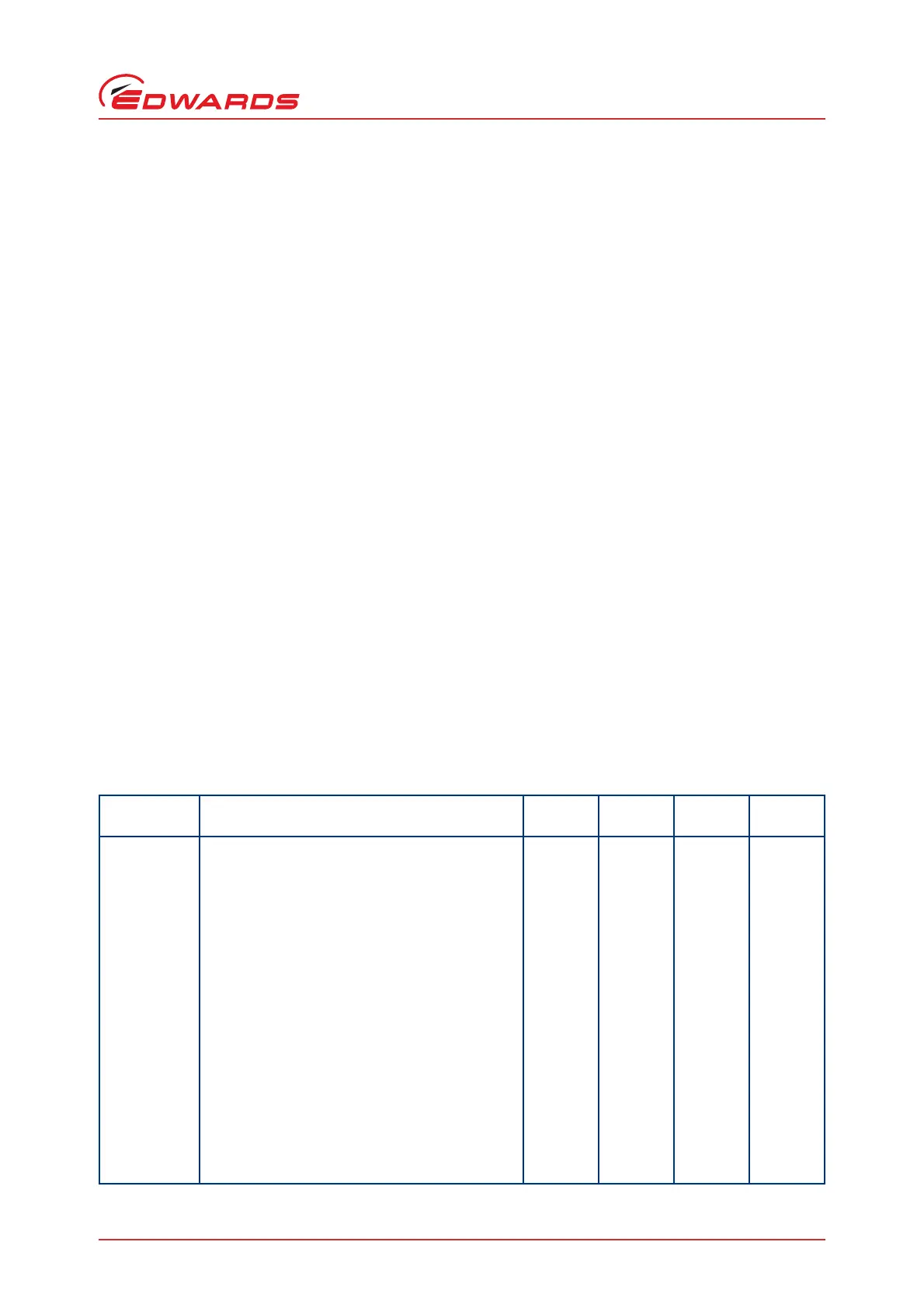

When you send a query message in simulation mode, the information returned in the reply message depends on the

selected simulated pumping system parameter, as shown in Table 15.

Other defaults in simulation mode are as follows:

z On process flag = reset.

z Run til crash = selected.

z Serial number = “Simulation<string>”, where <string> is either a number of spaces, or a number of spaces

followed by the issue status of the software in the iTIM.

Table 15 - Simulated Pumping System Data

{parameter} Description

{priority

level}

{alarm

type}

{bitfield

status}

{value}

1

*

Pump control

2 Electrical supply voltage 0 0 0 2818

3 Dry pump phase current 0 0 0 44

4 Dry pump power 0 0 0 24

5 Voltage reading from dry pump thermistor 0 0 0 230

6 Imbalance in dry pump phase current 0 0 0 30

7 Mechanical booster pump phase current 0 0 0 91

8 Mechanical booster pump power 1 11 0 45

9 Voltage reading from mechanical booster pump

thermistor

000564

10 Imbalance in mechanical booster pump phase

current

00010

11

*

Dry pump status

12 Mechanical booster pump status 0 0 0 4

13 Gas module supply 0 0 0 4

Loading...

Loading...