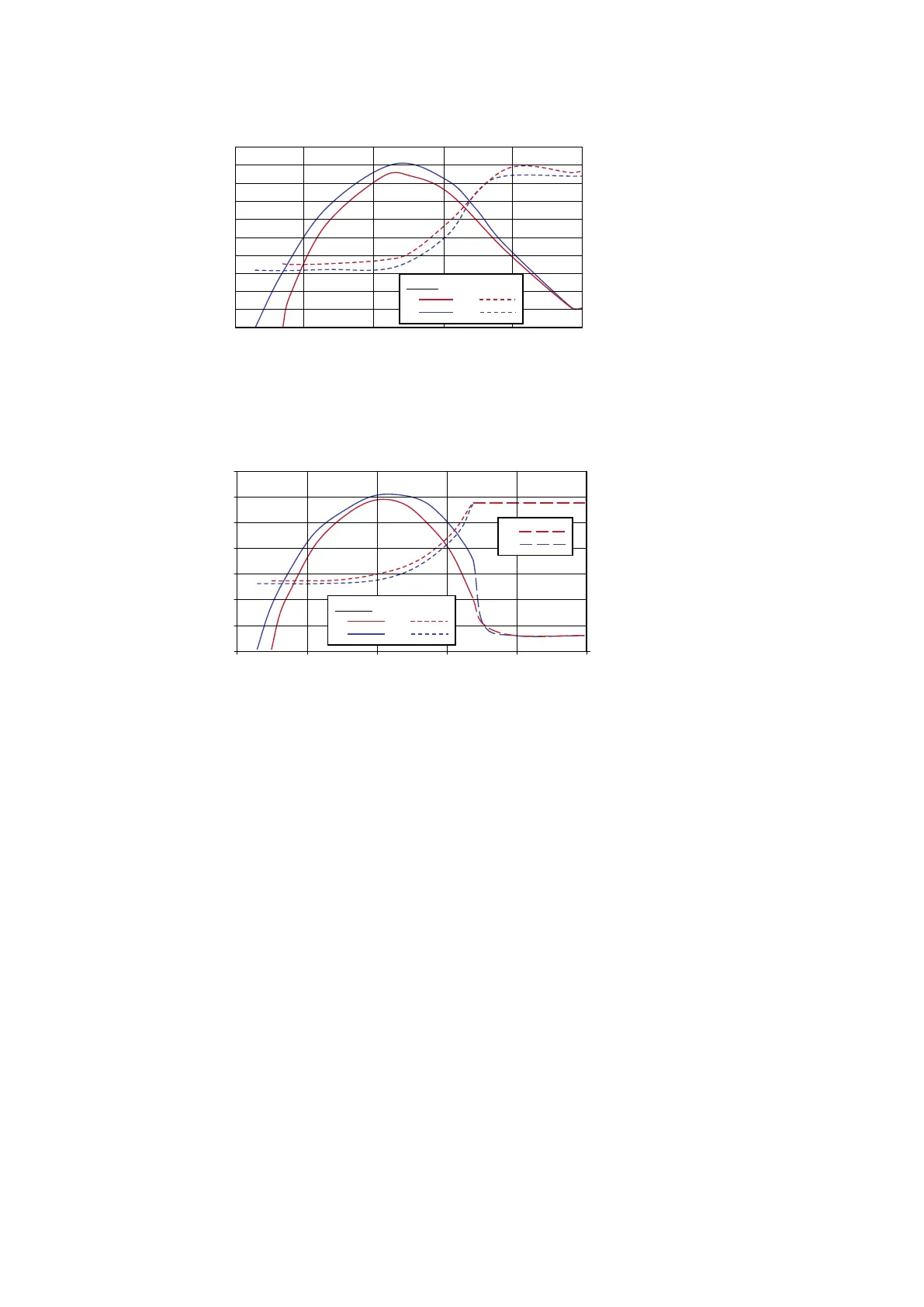

Figure 9 nXR90i performance curve

0.01 0.1 1 10 1000

0

90

10

20

30

50

60

70

80

40

100

100

0

400

800

1200

600

1000

200

1.

2.

nXR90i

3.

4.

Pressure (mbar)

Pumping speed (m

3

h

-1

)

Power consumption (Watt)

1. Pumping speed with gas ballast 2. Pumping speed without gas ballast

3. Power with gas ballast 4. Power without gas ballast

1. Pumping speed with gas ballast 2. Pumping speed without gas ballast

3. Power with gas ballast 4. Power without gas ballast

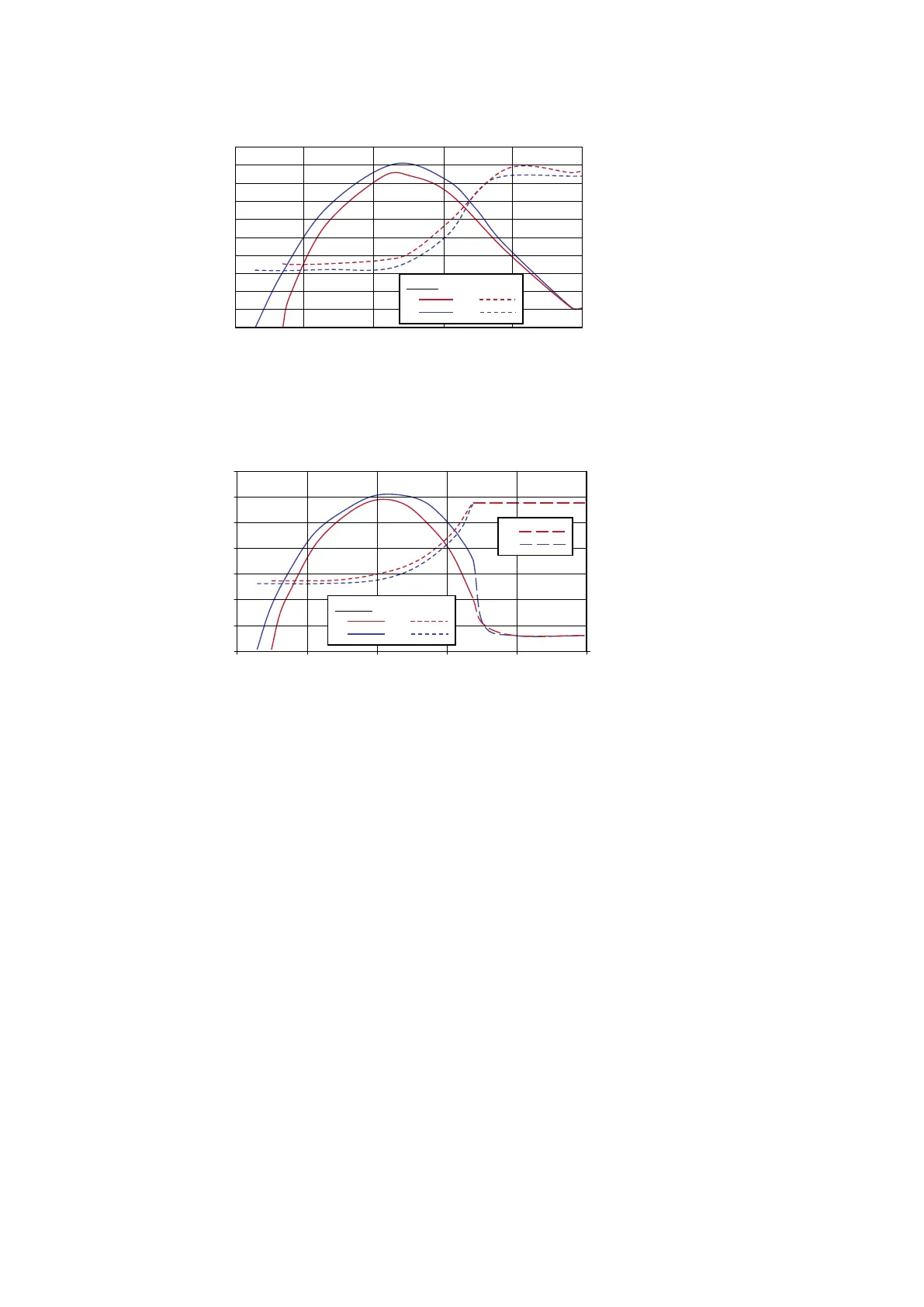

Figure 10 nXR120i performance curve

0

20

40

60

80

100

120

140

0.01 0.1 1 10 100 1000

0

400

800

1200

600

1000

200

1.

2.

nXR120i

3.

4.

5.

6.

Pressure (mbar)

Pumping speed (m

3

h

-1

)

Power consumption (Watt)

1. Pumping speed with gas ballast 2. Pumping speed without gas ballast

3. Power with gas ballast 4. Power without gas ballast

5. Non-connuous speed with gas ballas

t 6. Non-connuous speed without gas

ballast

1. Pumping speed with gas ballast 2. Pumping speed without gas ballast

3. Power with gas ballast 4. Power without gas ballast

5. Non-connuous speed with gas ballast 6. Non-connuous speed without gas

ballast

3.3 Materials exposed to gases pumped

The materials and the components exposed to the gases in the pump are:

▪ Iron

▪ Aluminium alloy

▪ Steel

▪ Fluoroelastomer (seals)

▪ PFPE lubricant

3.4 Electrical data

If the pump is operang with a supply voltage below the nominal operang range,

example < 200 V in high voltage regions or < 100 V in low voltage regions, the product

will limit the maximum power deliverable to the pump motor. If the applicaon load

exceeds the maximum power available, pump rotaonal speed will be reduced. Refer to

Figure: Speed vs Power graph. At lower rotaonal speeds pumping performance will be

05/2021 - ©Edwards Limited

Page 17A90301880_C

A90301880_C - Technical data

Loading...

Loading...