EASZ-2 Manual v1.12 - 12.2.2018 Page 12 / 30

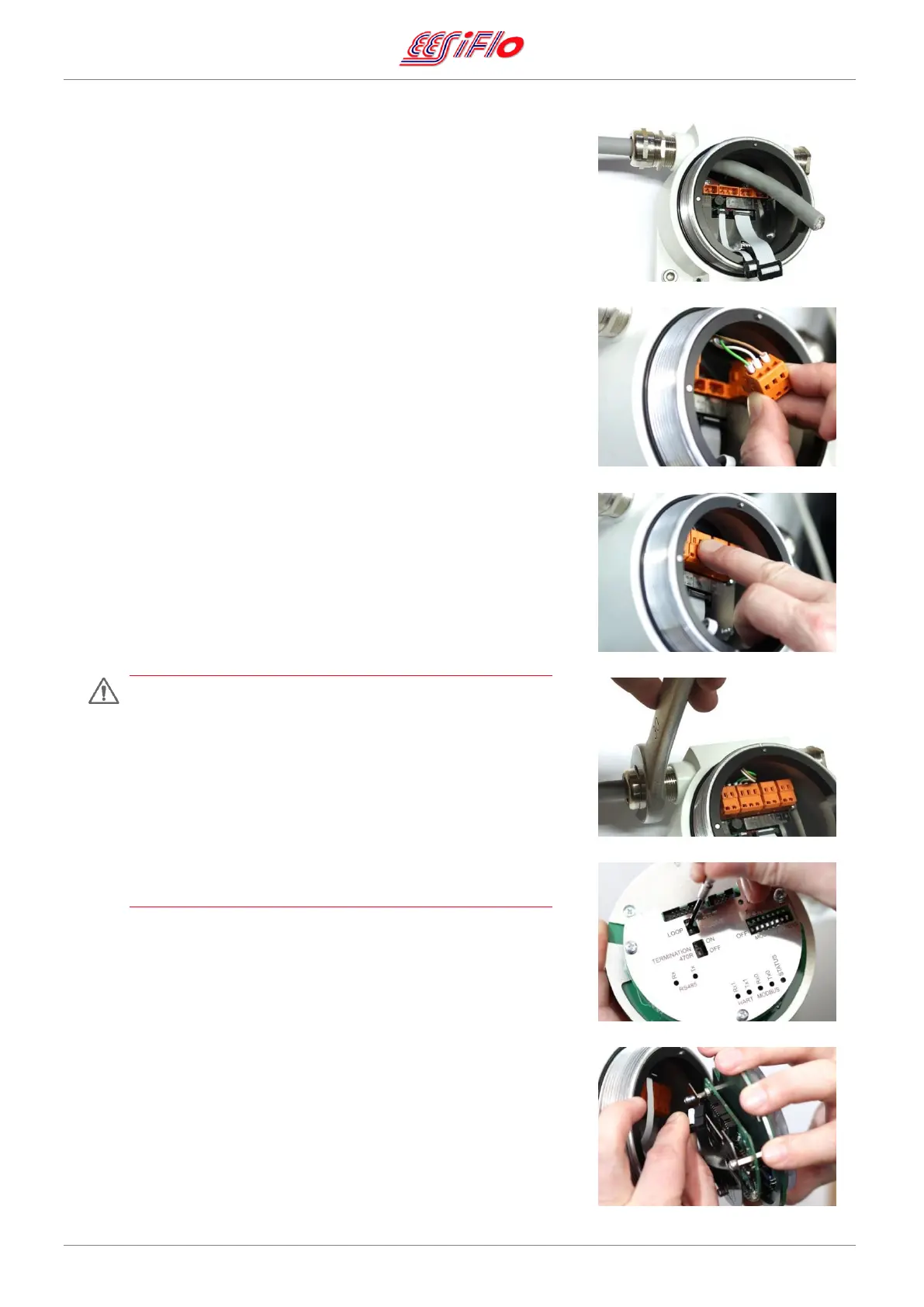

7) To make cable access easier remove all the orange

connector blocks.

8) Pass the incoming (and outgoing if used) cable through the

gland ensuring to leave a loop on the outside to avoid

running water into the unit, otherwise the IP certification

could be at risk and this will invalidated the warranty.

If the unit is mounted vertically then only use the bottom

gland and place a plug in the top position.

9) Strip and crimp the wire ends ensuring that the wires are

connected securely with no loose strands.

10) Connect the wires to the correct terminal blocks using a

screwdriver to lift the spring clip.

11) Once all the wires are connected correctly according to the

required connection option press the connectors firmly

back into their sockets to ensure a positive fit.

12) After all the connections are made all the glands must be

correctly tightened using a spanner. Take care not to

damage the cables by over tightening the glands.

When using EASZ-2Ex, all unused cable glands must be

removed and replaced with special Ex plugs.

The body of the Unit is a flameproof enclosure and it is

essential that all glands and plugs are correctly tightened to

the manufacturer’s torque settings, otherwise the certification

could be at risk, and the Ex protection could be compromised.

The cable glands supplied are NPT ¾” HSK-Ex-D and should

be correctly tightened to a torque of 30 Nm.

In the event that the cables or glands are found to be

damaged they must be replaced immediately.

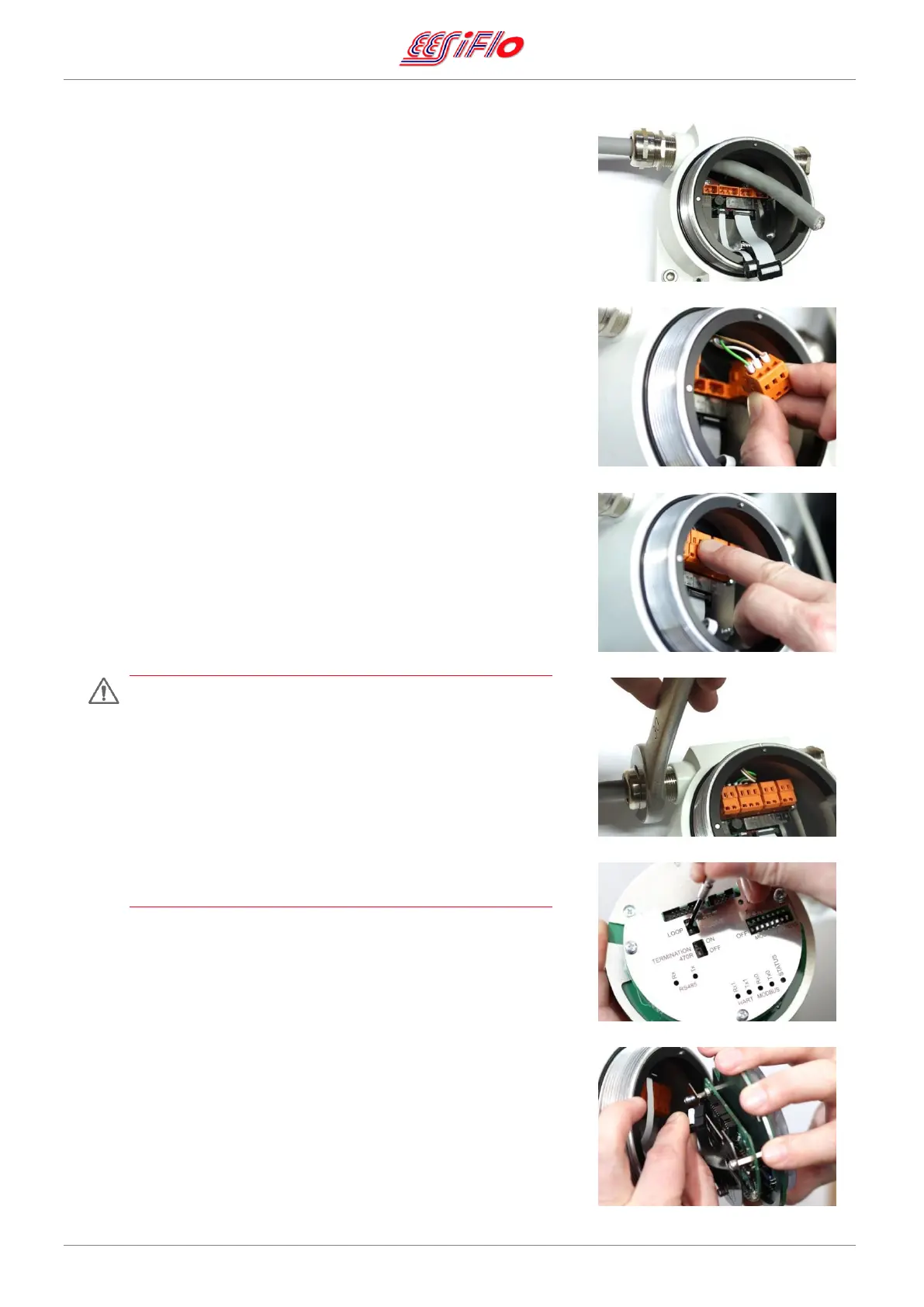

13) Configure the unit by setting the correct DIP switches on

the back of the display board according to the required

connection option.

Current Loop – Active or Passive

RS485 Termination resistor – On or Off

RS485 ModBus Address

14) Reconnect the ribbon leads to the back of the display

board.

Loading...

Loading...