Maintenance Tools

6" adjustable wrench

snap ring pliers

packing extraction tool #7803

Caution: Always release the reser-

voir pressure and disconnect the

power before performing any mainte-

nance on the system. On all EFD

tanks, there is a pressure relief valve

that should be activated before open-

ing the tank to ensure that all pres-

sure is bled off.

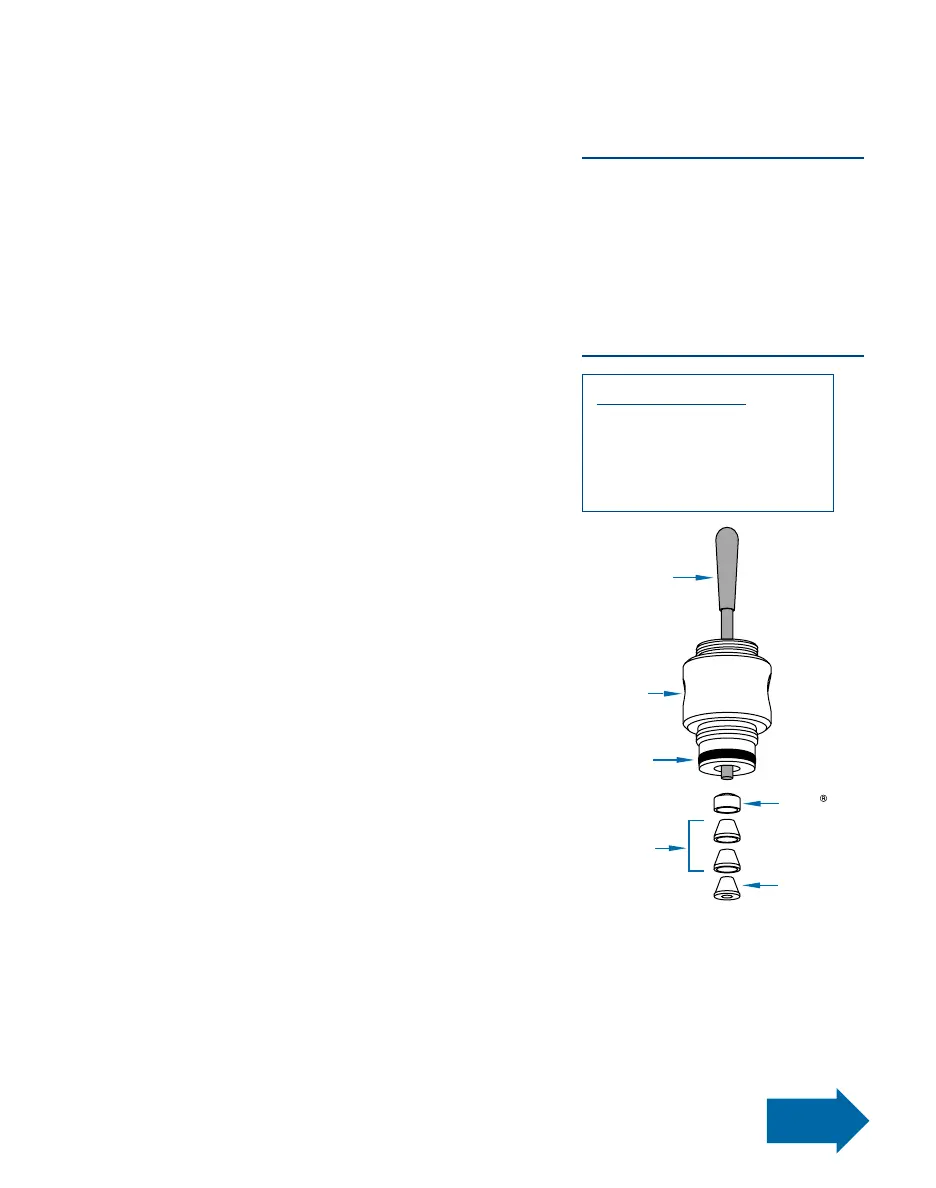

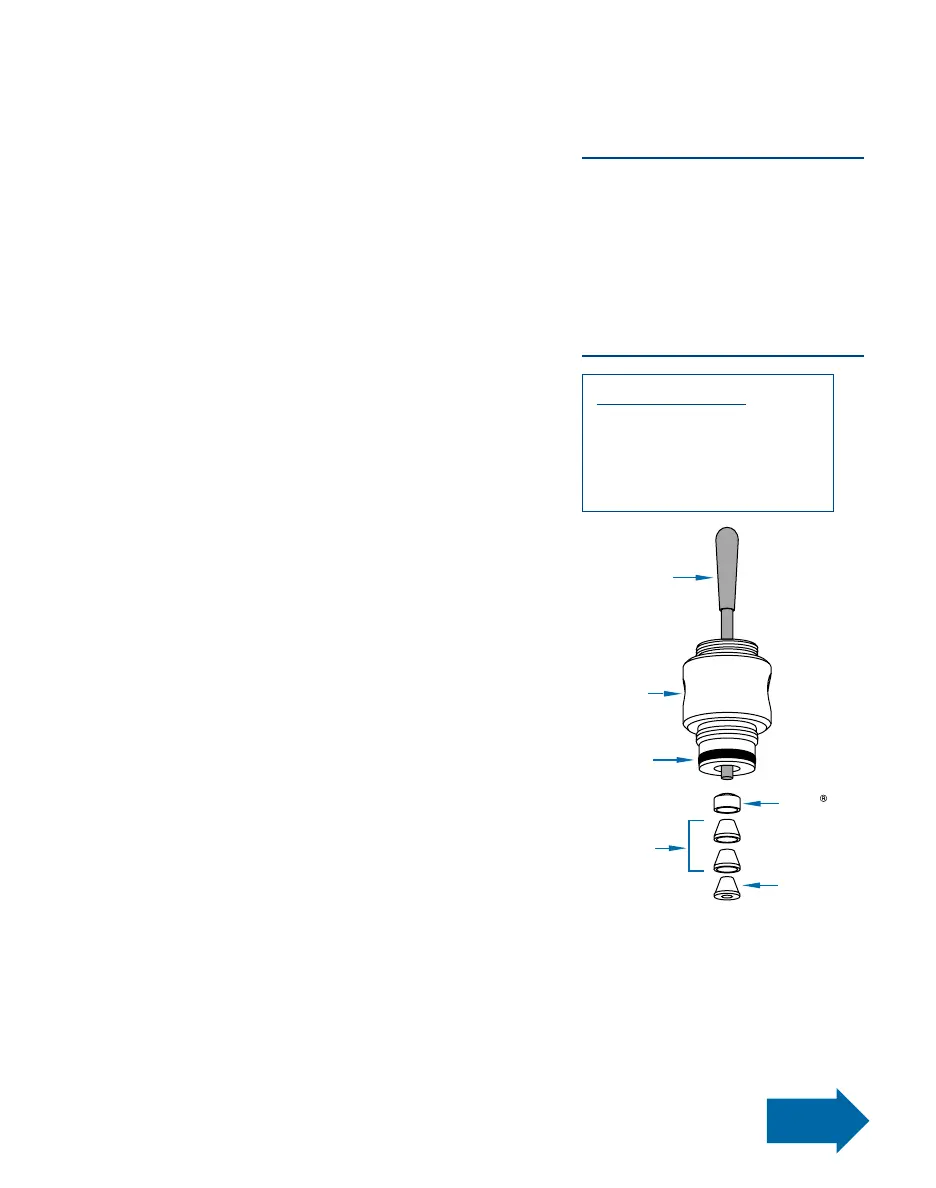

Valve Maintenance

Normal cleaning is accomplished by purging with

appropriate solvent. The air cap and nozzle can be

removed, soaked in solvent and reinstalled without

demounting the valve. (Refer to Exploded View on page

17.)

To thoroughly clean valve chamber and replace needle

packings:

1. Remove the needle stroke control knob and spring

to prevent damage to the needle and nozzle during

reassembly.

2. Remove the air cap retainer, then the air cap, nozzle

and fittings from the liquid chamber.

3. Remove the fluid chamber from the air cylinder

body by turning counterclockwise until free. Then

remove the O-ring from the fluid chamber.

4. Clean the fluid chamber, air cap and nozzle in

appropriate solvent.

5. Remove the needle packings from the fluid cham-

ber, using tool #7803 supplied with the valve. Insert

through nozzle end of the fluid chamber and gently

push out the packings (see Figure 1).

Do not use sharp instruments to scrape or clean

these components. Scratches may cause the valve

to leak.

6. Remove any remaining packings and the spring

14 / Valve Maintenance

Figure 1

Pushing needle packings

from the fluid chamber.

Loading...

Loading...