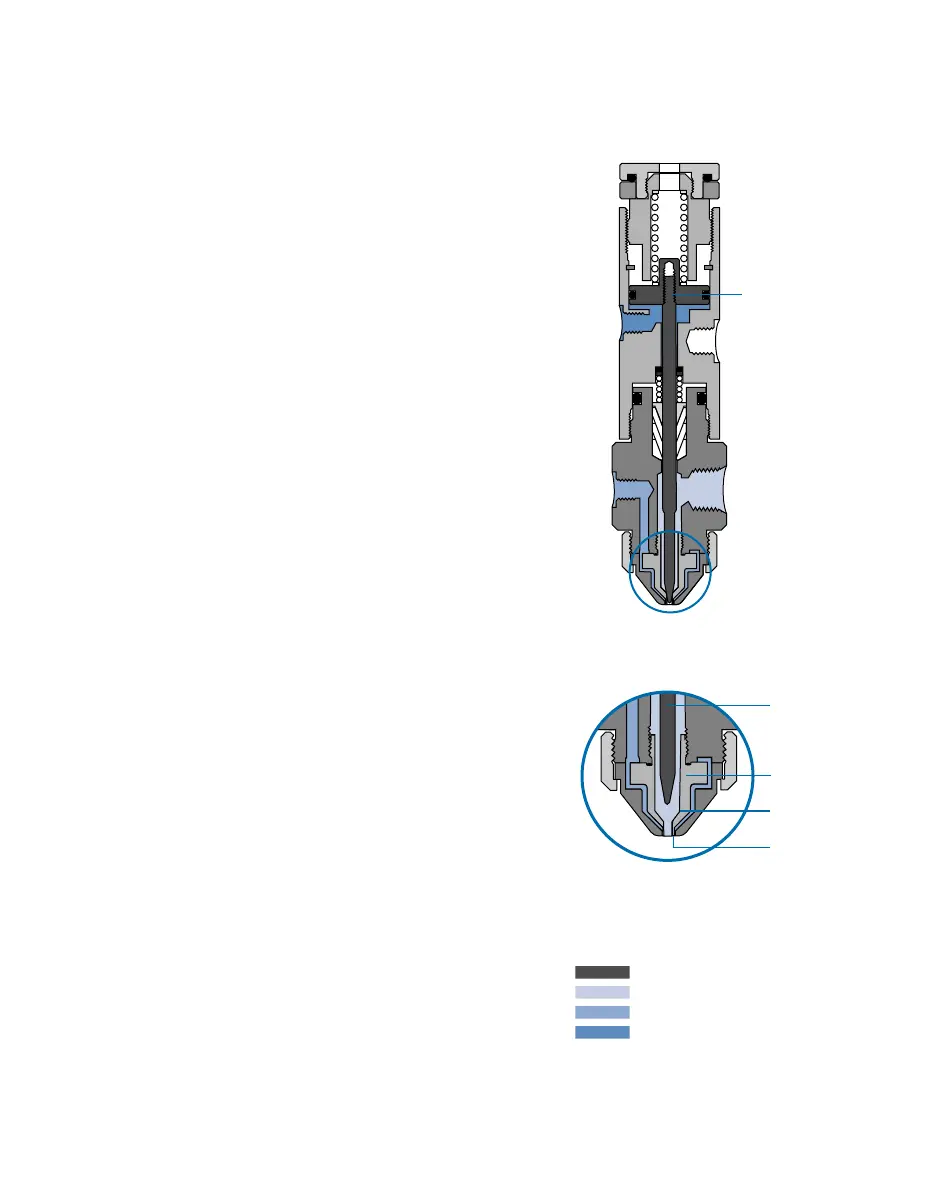

How The Valve and Controller Operate

open position

The 780S is a normally closed, air actuated needle

type spray valve that uses a Low Volume Low

Pressure (LVLP) design for high transfer efficiency

without overspray or airborne mist.

Air pressure from the VALVEMATE

™

7040 controller at

70 psi (4.8 bar) acts on a piston

➀

that retracts the nee-

dle ➁ from its nozzle seat ➂ and allows liquid to flow

from the nozzle ➃. At the same time, nozzle air, also

from the 7040, is turned on and flows from an annulus

➄ around the liquid nozzle.

This adjustable nozzle air creates a pressure drop

around the nozzle, causing the liquid to atomize into

fine droplets.

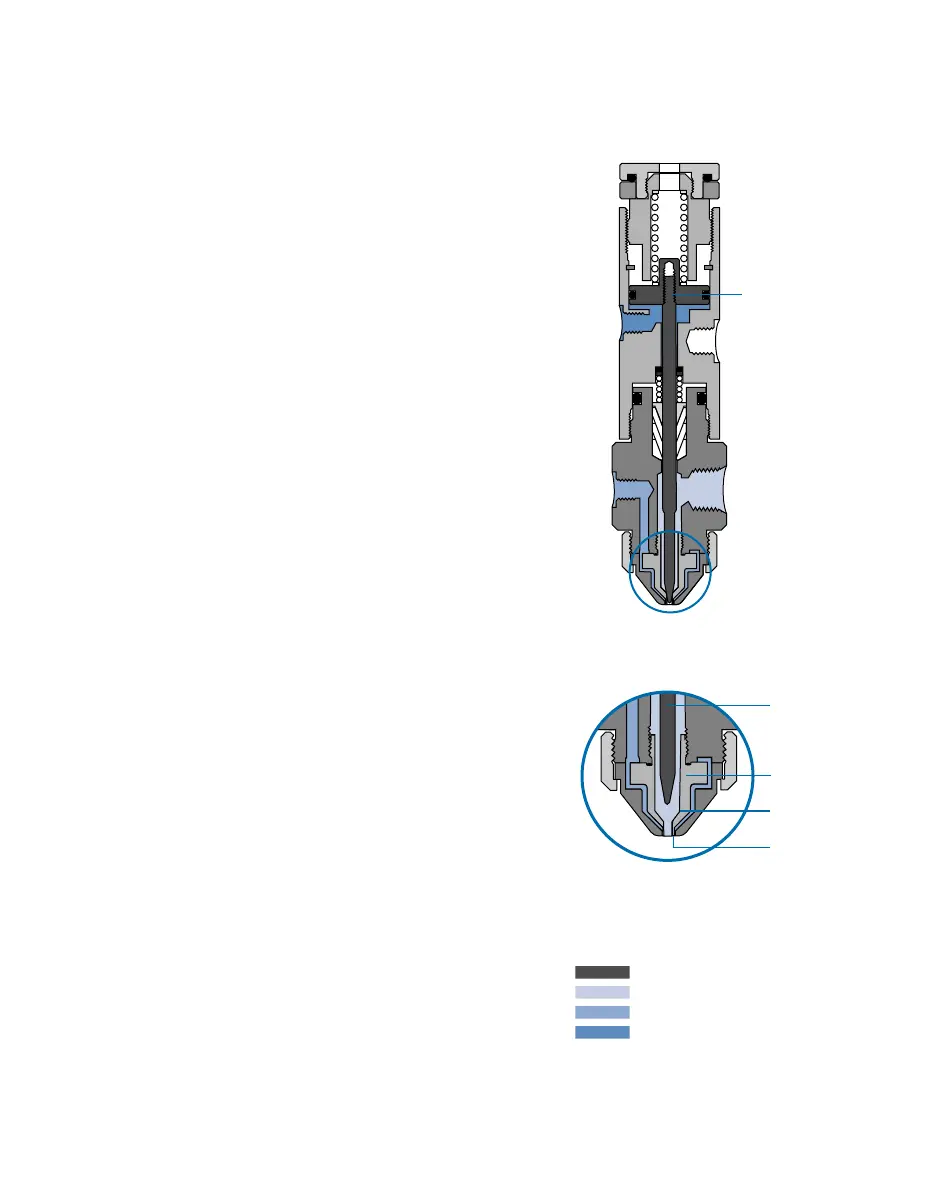

When the timed actuating air from the 7040 shuts off,

the piston spring moves the needle onto the nozzle

seat, shutting off liquid flow. A preset nozzle air delay

ensures that no liquid remains on the nozzle after the

valve closes, eliminating after-deposit spatter.

The amount sprayed is controlled by the valve open

time, reservoir pressure and needle stroke. Area of

coverage is determined by the nozzle size and the dis-

tance between the 780S nozzle and the work surface.

closed position

4 / How The Valve and Controller Operate

Loading...

Loading...