using sterile compressed air.

Functional

Testing,

Maintenance

Visual inspection for cleanliness of the

instruments and reassembling. Functional testing

according to instructions of use. If necessary,

perform reprocessing process again until

instrument is visibly clean.

Before packaging and autoclaving, make sure

that the components have been maintained acc.

to manufacturer’s instruction.

Only the contra angle needs to be lubricated.

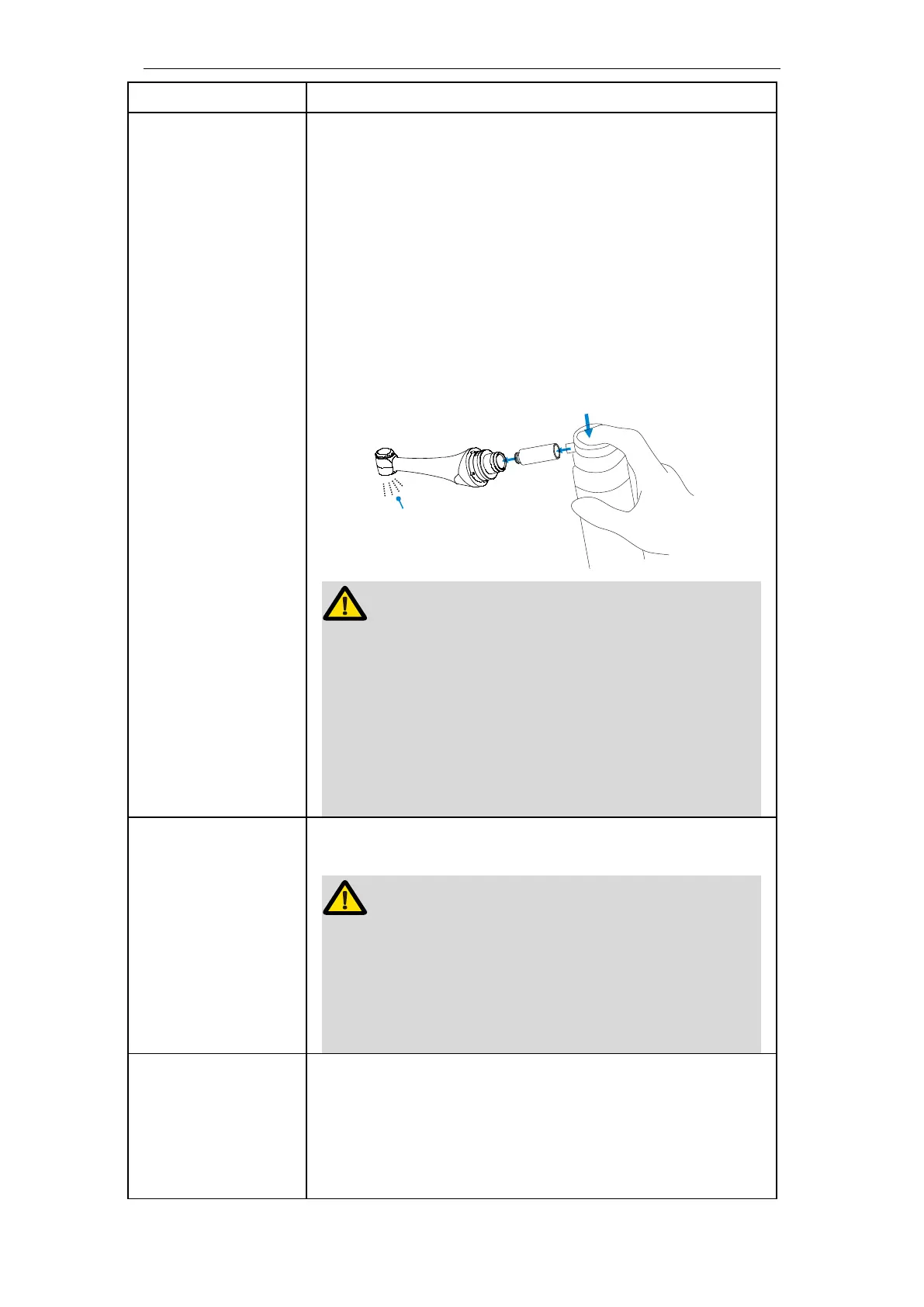

1. Before autoclaving, the contra angle must be

lubricated.

2. Attaching the spray nozzle to oil can and

contra angle, press the oil can button more

than 3 seconds, till all the black oil flow out

from the head of the contra angle.

Pack the instruments in an appropriate

packaging material for sterilization.

1. Check the validity period of pouch given by the

manufacturer to determine the shelf life.

2. Use pouches which resist to a temperature up

to 141℃ and in accordance with EN ISO 11607.

Sterilization of instruments by applying a

fractionated pre-vacuum steam sterilization

process (according to EN 285/EN 13060/EN ISO

17665) under consideration of the respective

country requirements.

Loading...

Loading...