2 Operating conditions and

specifications

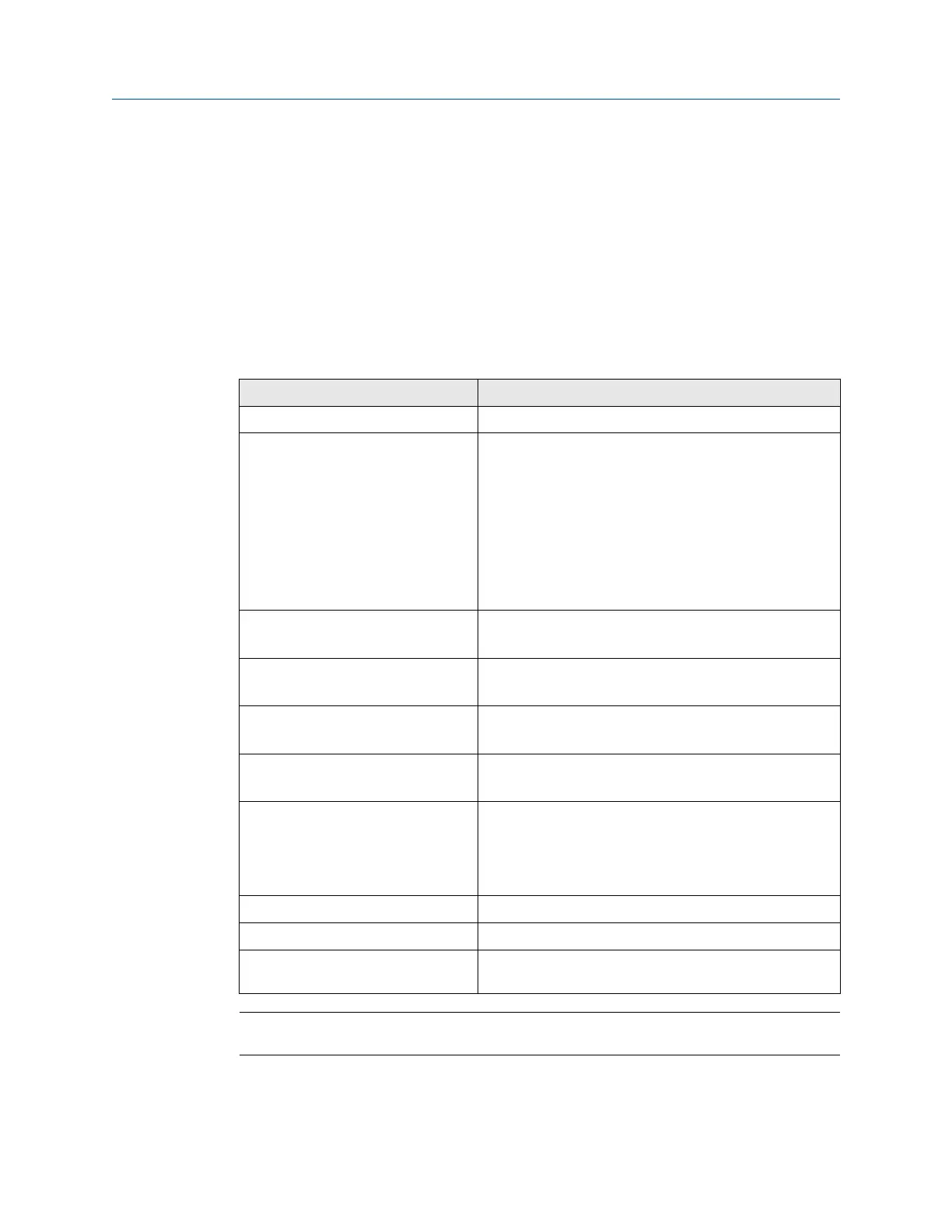

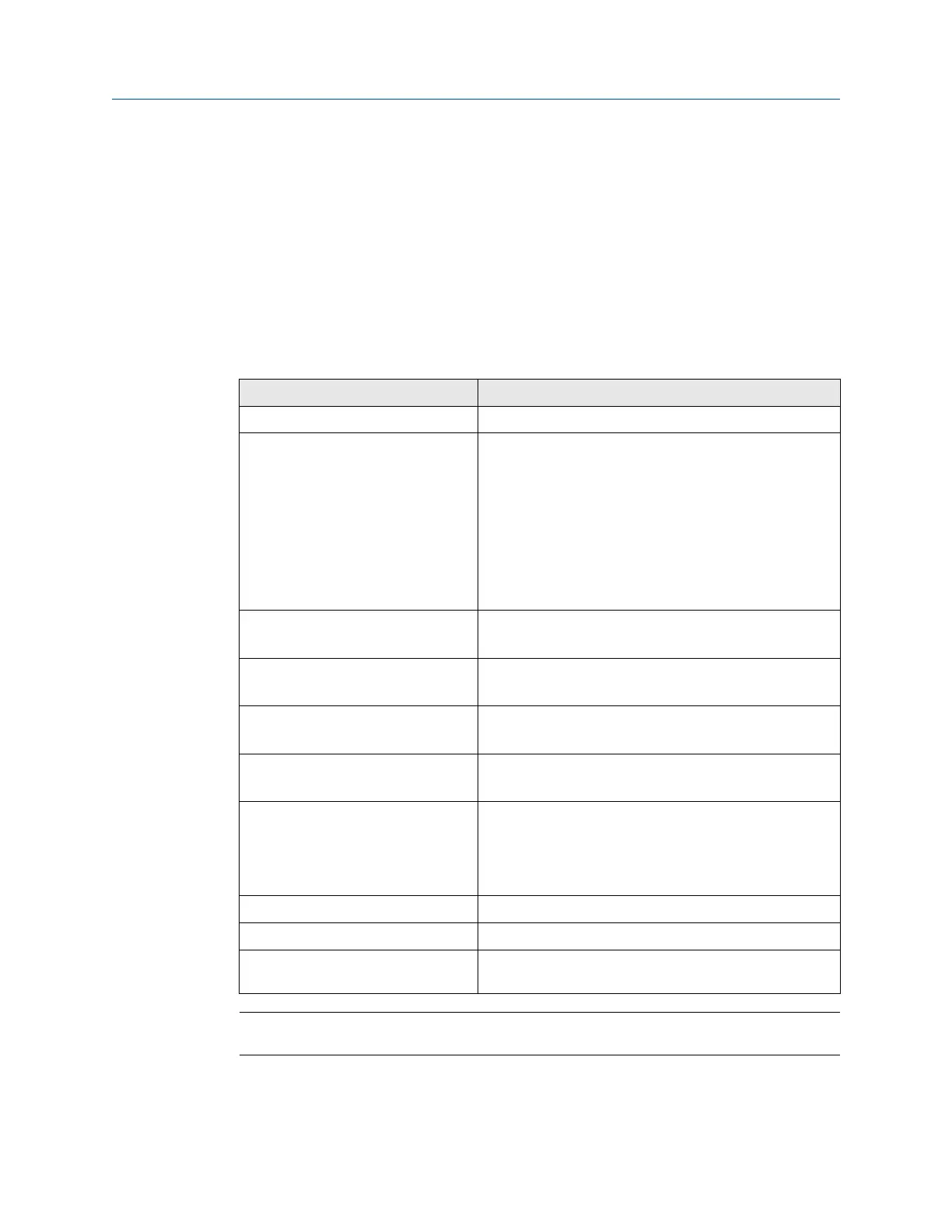

2.1 Operating conditions for the liquid turbine

meter

Table 2-1: Operating conditions for the liquid turbine meter

Parameter type Description

Fluid phase Liquid

Fluid(s) measured • Low/medium viscosity crude oils and condensates

• Refined products and intermediates (e.g.: gasoline,

diesel, kerosene, light fuel oils, jet fuel, LPG, butanes,

naphtha, alkylate, reformate, straight run gasoline, cat-

cracked gasoline)

• Petrochemicals (e.g.: benzene, toluene, xylenes, cumene,

olefins, pyrolysis gasoline)

• Natural gas liquids

Process temperature

(Carbon steel flanges)

-29 ºC to 60 ºC (-20 ºF to 140 ºF)

Optional process temperature

(Carbon steel flanges)

-29 ºC to 204 ºC (-20 ºF to 400 ºF)

Process temperature

(Stainless steel flanges)

-40 ºC to 60 ºC (-40 ºF to 140 ºF)

Optional process temperature

(Stainless steel flanges)

-40 ºC to 204 ºC (-40 ºF to 400 ºF)

Fluid static pressure The maximum working pressure for the Daniel Series 1500

Liquid Turbine Meter is based on the temperature/

pressure rating of the ANSI B16.5 flanges. For maximum

working pressures at intermediate temperatures refer to

ANSI B16.5.

Fluid flow rate 100 BPH – 60000 BPH

Pressure drop At maximum flow of normal flow range on water 4 psi.

Ambient temperature -40 ºC to 60 ºC (-40 ºF to 140 ºF) (T

amb

is an electrical

specification)

Note

Remote mount the LME when the ambient temperature is above 60 °C (140 °F).

User manual Operating conditions and specifications

P/N 3-9008-515 March 2019

User manual 41

Loading...

Loading...