10 Corrective maintenance

10.1 Turbine meter troubleshooting

Use the table below to troubleshoot the turbine meter. Contact the nearest Daniel

Measurement and Control Sales or Service office for repairs. It is important that servicing

be performed by trained and qualified service personnel.

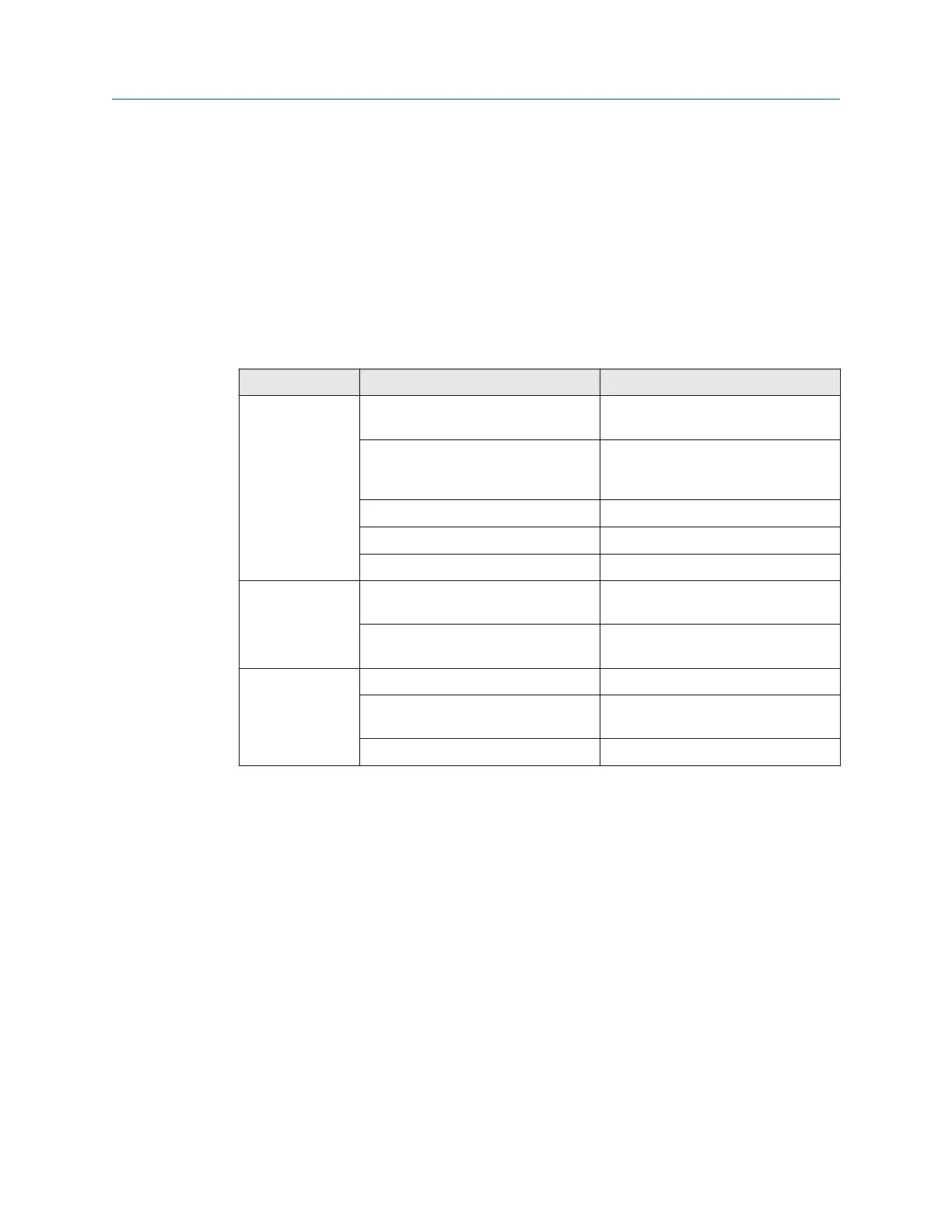

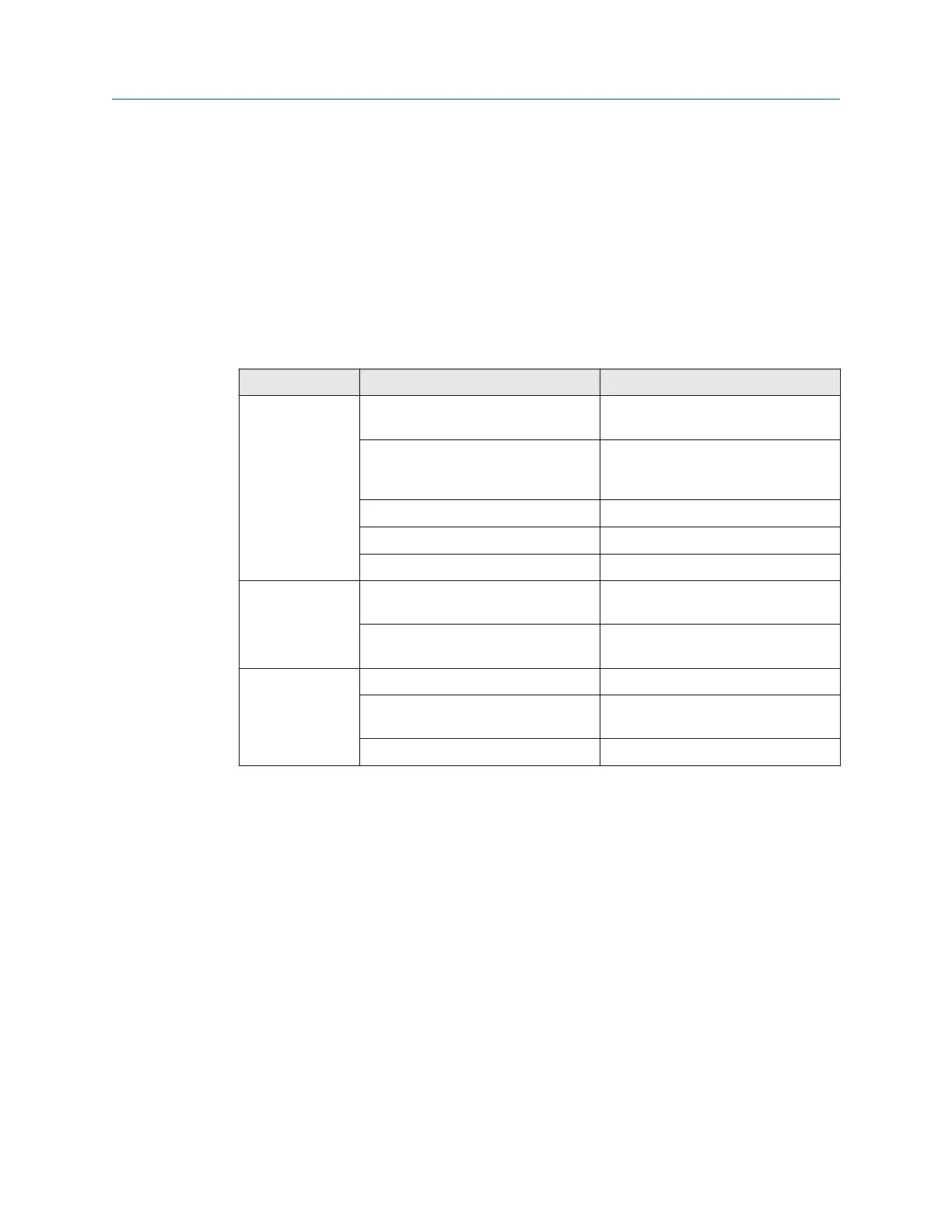

Table 10-1: Troubleshooting

Condition Probable cause Correction

(1)

No output pulses

from amplifier

module

Input voltage to amplifier below

minimum required for operation

Apply correct voltage (10 - 30 VDC)

Damaged or shorted pickoff

(Resistance across leads should be

600-900 Ohm)

Replace pickoff

Damaged amplifier module Replace amplifier module

Customer receiver unit not operating Contact Daniel Customer Service

Meter rotor not turning Troubleshoot internal assembly

Turbine meter

rotor not turning

Defective rotor bearing Return rotor assembly to factory for

replacement or repair

Rotor damaged by foreign material

passing through turbine meter

Return rotor assembly to factory for

replacement or repair

Inaccurate

readout

Foreign material on rotor blades Check and clean blades

Rotor blades are bent Return to factory for replacement or

repair

Defective accessory equipment Troubleshoot equipment

(1) * Refer to Prepare for mechanical disassembly for disassembly procedures.

10.2 Verify the return to operational condition

After correcting maintenance issues, verify that the turbine meter is working properly by

following the steps below.

Procedure

1. Inspect all electrical connections to ensure compliance with electrical codes and

safety regulations.

2. Inspect all flange bolts used to secure the turbine meter in-line to ensure that

correct mounting procedures are followed and that flange connections are leak-

free.

3. Evaluate the system setup to ensure that all components are in the correct

sequence for accurate product measurement: isolation valve, strainer, flow

straightener, turbine meter, downstream section, control valve, etc.

User manual Corrective maintenance

P/N 3-9008-515 March 2019

User manual 99

Loading...

Loading...