9.4 Mechanical assembly

Protection for rotor blades from rough handling as blade position is critical to turbine

meter performance.

Use appropriate torque values to reinstall the shaft nut and to avoid equipment damage or

inaccurate turbine meter operation.

Important

The shaft nut can only be reused up to five times. Replace as needed.

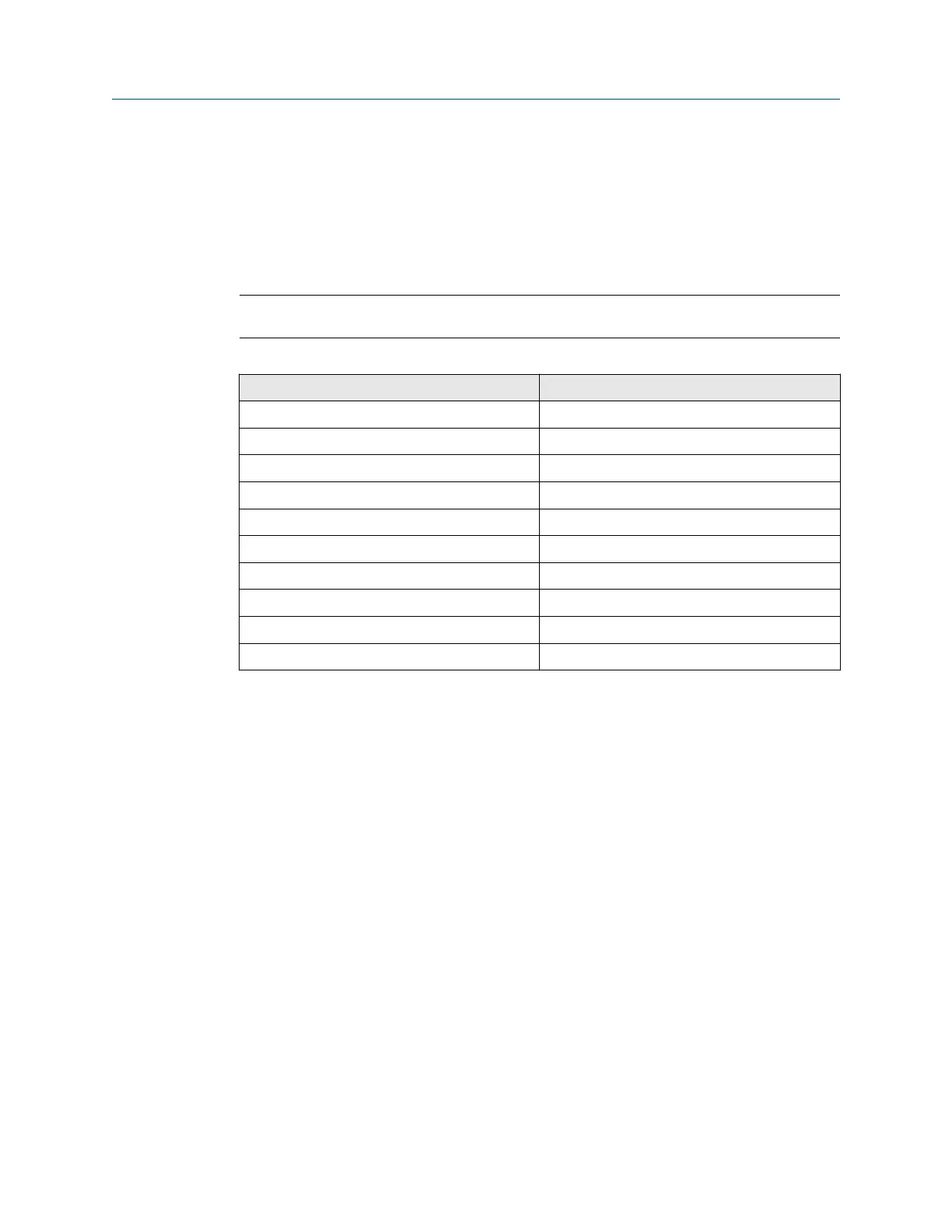

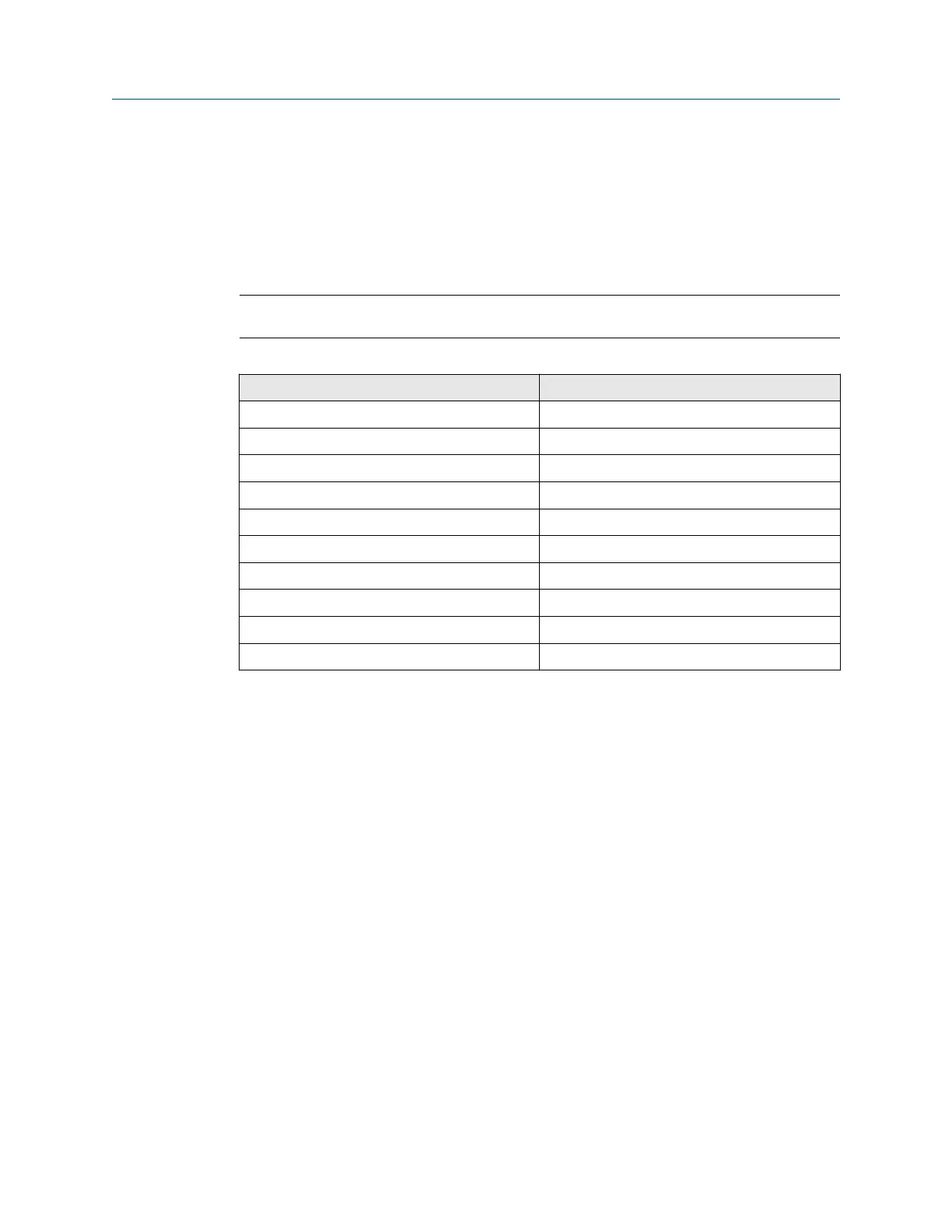

Table 9-1: Torque requirements for shaft nut reinstallation

Turbine meter size Torque requirement

3 7.9 n-m (70 in-lbs)

4 11.3 n-m (100 in-lbs)

6 67.7-81.3 n-m (50-60 ft-lbs)

8 67.7-81.3 n-m (50-60 ft-lbs)

10 81.3-95 n-m (60-70 ft-lbs)

12 95-122 n-m (70-90 ft-lbs)

16 108-135 n-m(80-100 ft-lbs)

18 108-135 n-m (80-100 ft-lbs)

20 108-135 n-m (80-100 ft-lbs)

24 108-135 n-m (80-100 ft-lbs)

9.4.1 Assemble internal meter housing components -NPS 3

through 24

Procedure

1. Install the upstream hanger assembly in the inlet side. Secure the upstream hanger

by tapping the hanger assembly with a plastic hammer.

User manual Planned maintenance

P/N 3-9008-515 March 2019

User manual 91

Loading...

Loading...