3.2.3 Storage conditions

Store the turbine meter in a safe area to avoid damage.

WARNING

CRUSHING HAZARD

During turbine meter installation or removal, always place the unit on a stable platform

or surface that supports its assembled weight.

Failure to comply could allow the turbine meter to roll, resulting in death, serious injury

or equipment damage.

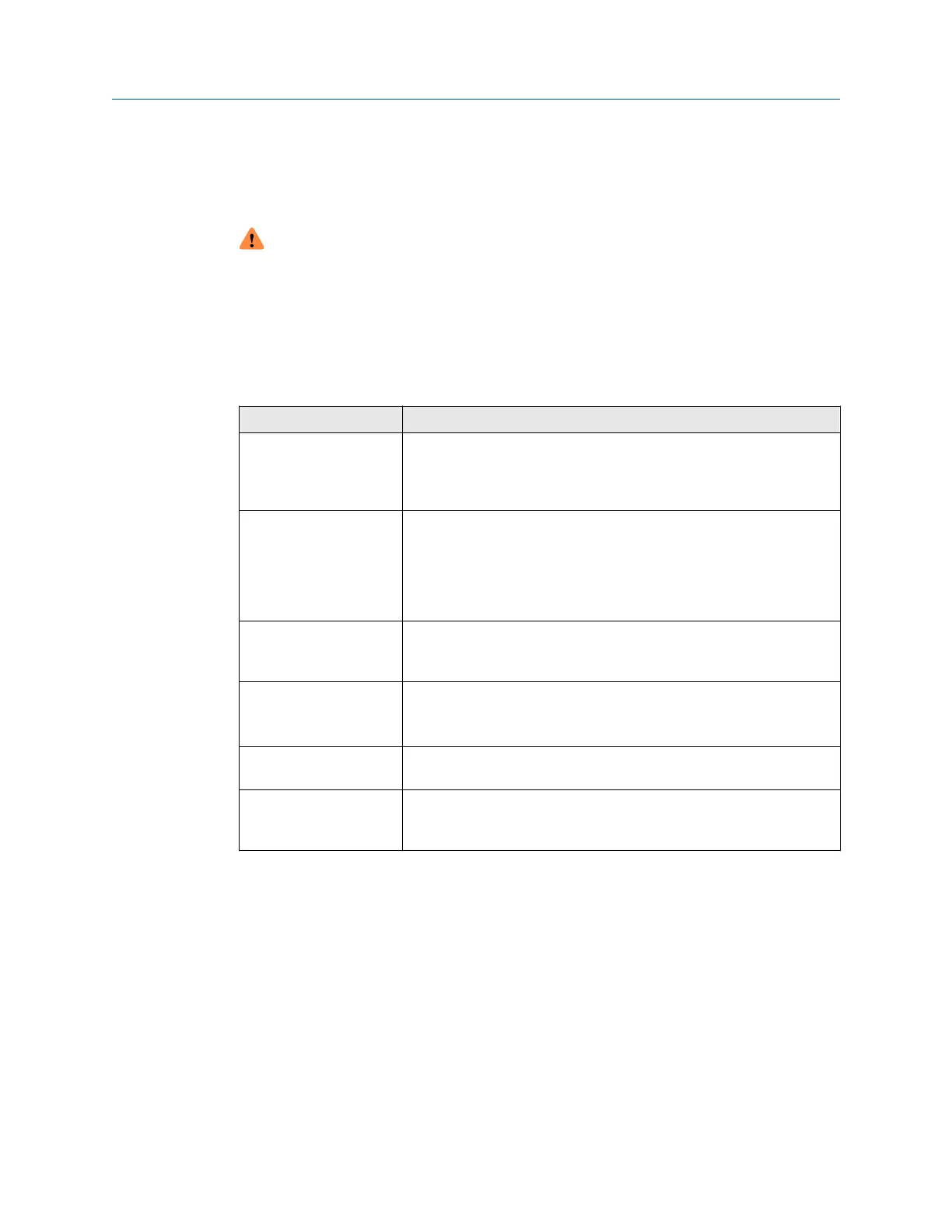

Table 3-1: Meter storage conditions

Parameter type Description

Storage environment For long term storage, it is recommended that the complete meter

housing assembly be stored under cover in a controlled environmental

atmosphere in the original packaging. The storage temperature limits

are -40 ºC to 60 ºC (-40 ºF to140 ºF).

Shelf life for elastomers Elastomers are only installed in a flameproof pad and a threaded top

cover. These parts are not considered to be under pressure in normal

conditions. O-rings must be inspected for wear or damage during

disassembly of the cover or housing and right before assembling the

unit. If any elastomer is damaged, it must be replaced. FKM elastomers

have an unlimited shelf life.

Lubrication The LME is offered in stainless steel. Use petroleum jelly lubrication

when assembling the cover to the LME housing. Other components,

except O-rings do not require lubrication.

Inspect stored

equipment

Examine the internal surfaces and flange faces of the turbine meter at

least once every three months.

Repack the turbine meter per original conditions.

Labels and nameplates Do not remove nameplates or labels. Doing so will void the turbine

meter warranty.

Stacking When stacking equipment, follow all safety standards, taking into

account the type of box used, the maximum height of the equipment,

the maximum number of boxes stacked, etc.

Turbine meter handling User manual

March 2019 P/N 3-9008-515

56 Daniel Series 1500 Liquid Turbine Meter, NPS 3-24

Loading...

Loading...