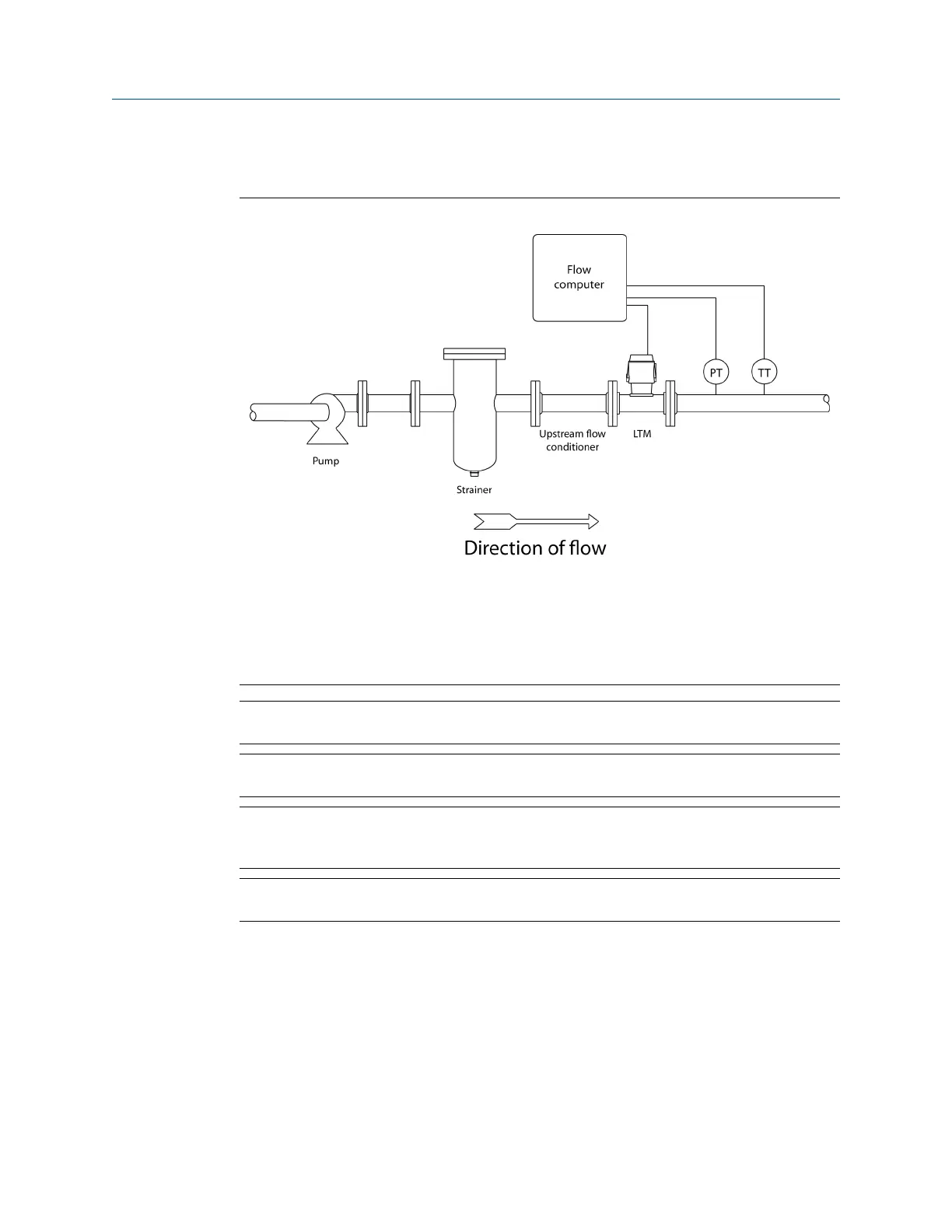

4.3.2 Piping recommendations

Figure 4-3: Typical installation for a Series 1500 LTM

• Note the direction of flow indicated on the plate near the inlet flange and install

accordingly.

• New installations: Flush lines thoroughly to rid piping of potentially damaging foreign

material such as welding bead, pipe scale, etc. before the turbine meter is placed into

service.

Important

A spool piece installed in place of the turbine meter is recommended for this procedure.

NOTICE

Comply with local government regulations and company requirements.

Important

Ensure that piping or other attachments connected to the turbine meter are not under

stress.

Important

Provide fire prevention measures and equipment per local regulations.

Prepare the turbine meter for use User manual

March 2019 P/N 3-9008-515

62 Daniel Series 1500 Liquid Turbine Meter, NPS 3-24

Loading...

Loading...