Chapter 5 Parameter Introductions 45

EV2000 Series Universal Variable Speed Drive User Manual

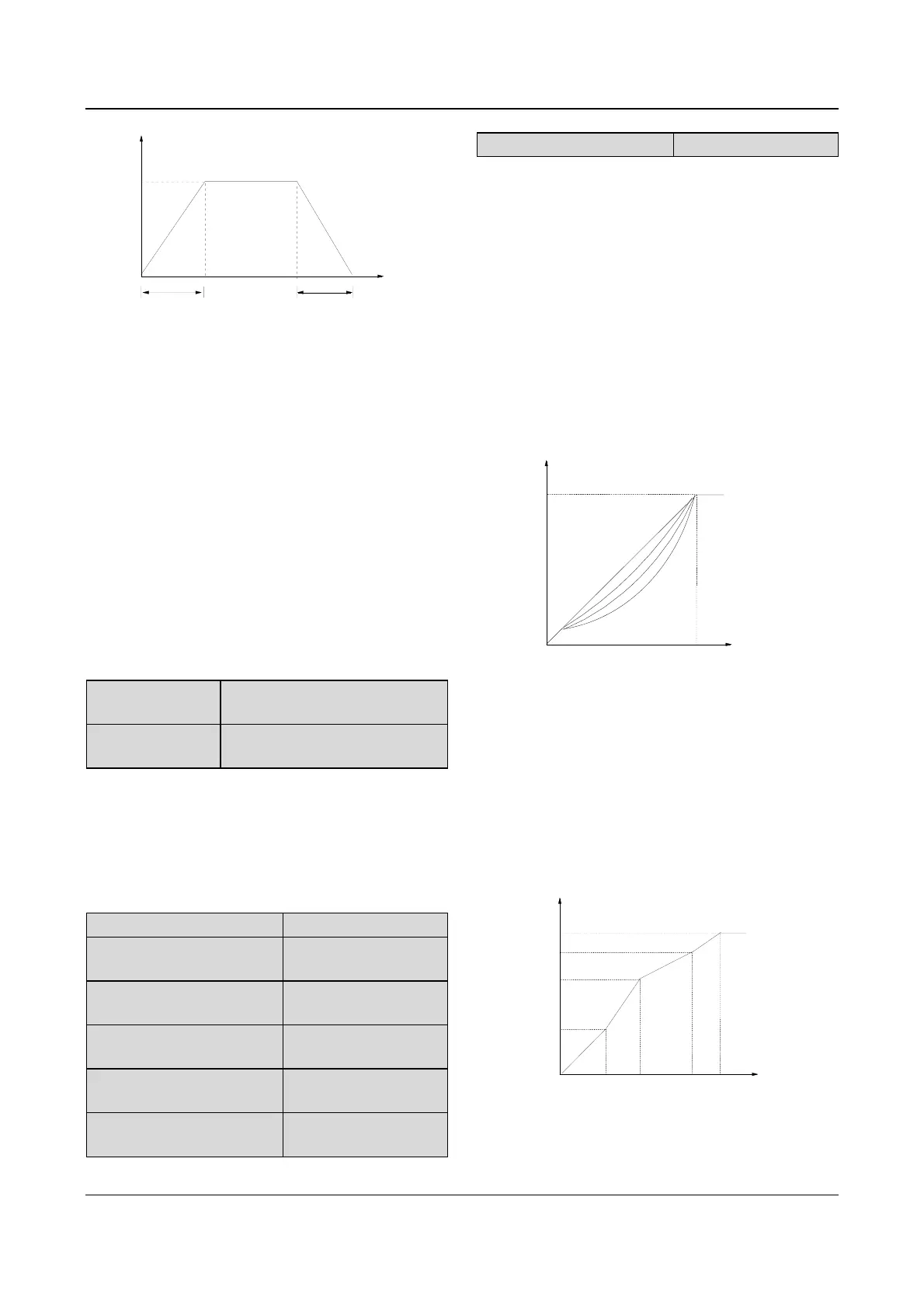

Output

frequency

t

1

f

max

t

2

Time

Fig. 5-4 Acc/Dec time definition

Acc time is the time taken for the motor to accelerate

from 0Hz to the maximum frequency (as set in F0.04),

see t

1

in Fig. 5-4.

Dec time is the time taken for the motor to decelerate

from maximum frequency (F0.05) to 0Hz, see t

2

in Fig.

5-4.

EV2000 series drive has defined 4 kinds of Acc/Dec

time. Here only Acc/Dec time 1 is defined, and Acc/Dec

time 2~4 will be defined in F3.17~F3.22, please refer to

section 5.4.

Note:

1. Unit(second/minute) of Acc/Dec time 1~4 is dependent

on the setting of F9.09, and the default unit is second.

2. For the drive of 30kW or above, the factory setting of

Acc/Dec time is 20.0s.

F0.12 upper limit of

frequency

Range: Lower limit of frequency

~Max output frequency【50.00Hz】

F0.13 lower limit of

frequency

Range:0~upper limit of frequency

【0.00Hz】

F0.12 and F0.13 define the upper and lower limit of

frequencies respectively, as shown in Fig. 5-2 as f

H

and

f

L

.

Notes:

Actual output frequency is possible to exceed ±2.5Hz in

the bus-voltage control process.

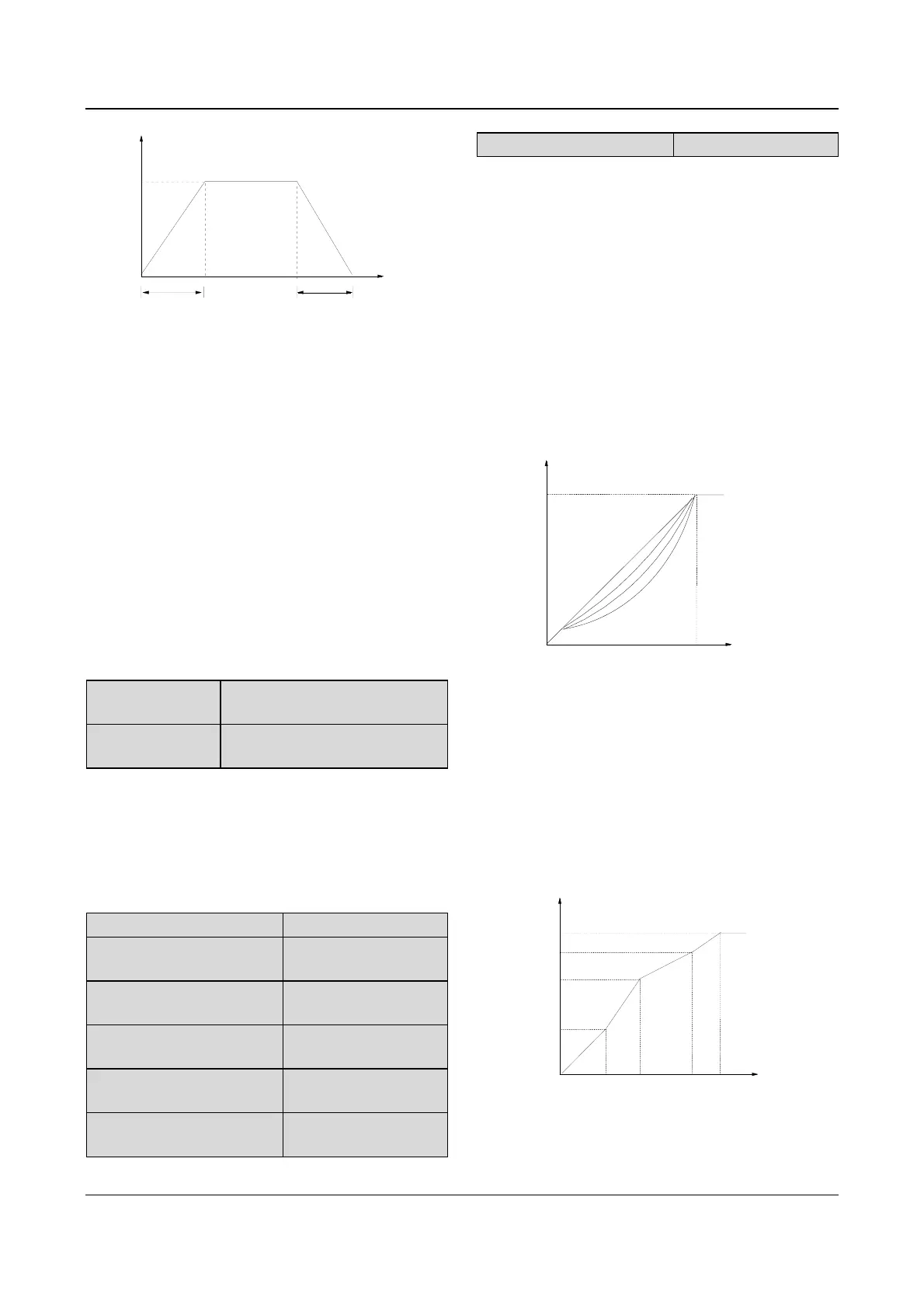

F0.14 V/F curve setting

Range: 0~3【0】

F0.15 V/F frequency value F3

Range: F0.17~F0.06

【0.00Hz】

F0.16 V/F voltage value V3

Range: F0.18~100.0%

【0.0%】

F0.17 V/F frequency value F2

Range: F0.19~F0.15

【0.00Hz】

F0.18 V/F voltage value V2

Range: F0.20~F0.16

【0.0%】

F0.19 V/F frequency value F1

Range: 0~F0.17

【0.00Hz】

F0.20 V/F voltage value V1

Range:0~F0.18【0.0%】

This group of parameters define the V/F setting modes

of EV2000 so as to satisfy the requirements of different

loads. 3 preset curves and one user-defined curve can

be selected according to the setting of F0.14.

If F0.14 is set to 1, a 2-order curve is selected, as shown

in Fig. 5-5 as curve 1;

If F0.14 is set to 2, a 1.7-order curve is selected, as

shown in Fig. 5-5 as curve 2;

If F0.14 is set to 3, a 1.2-order curve is selected, as

shown in Fig. 5-5 as curve 3;

The above curves are suitable for the variable-torque

loads such as fan & pumps. You can select the curves

according to the actual load so as to achieve best

energy-saving effects.

0

1

Output voltage (V)

Output frequency (Hz)

2

3

f

: Max output voltage(F0.07)

: Basic operating frequency(F0.06)

0

V

max

V

max

f

b

b

Fig. 5-5 Torque-reducing curve

If F0.14 is set to 0, you can define V/F curve via

F0.15~F0.20, as shown in Fig. 5-6. The V/F curve can

be defined by connecting 3 points of (V1,F1), (V2,F2)

and (V3, F3), to adapt to special load characteristics.

Default V/F curve set by factory is a direct line as show

in Fig. 5-5 as curve 0.

Voltage (%)

Freq Hz

Fb

100%

V1

V2

F1

F2

V3

F3

V1~V3: Voltage of sections 1~3

F1~F3: Freq of sections 1~3

Fb: Basic operating freq. of F0.06

Fig. 5-6 V/F curve defined by user

Loading...

Loading...