74 Chapter 5 Parameter Introductions

EV2000 Series Universal Variable Speed Drive User Manual

control mode is selected, the LED turns off; when serial

port control mode is selected, the LED flashes.

Note:

After selecting a control mode by using PANEL/REMOTE,

be sure to press ENTER/DATA key to confirm within 3

seconds.

Hundred’s place: Locking panel

0: not lock any key on the panel.

1: Locking up function is enabled and all keys on the

panel are locked up.

2: Except STOP/RESET, other keys are locked up.

3: Except XX, other keys are locked up.

4: Except RUN and STOP, all other keys are locked up.

After setting the parameter, you have to do certain

operation on the keypad to lock the panel. Please refer

to Figure 4-8.

F9.08 Fan control mode

Range:0. 1【0】

0: Auto stopping mode

The fan runs all the time when the drive is operating.

After the drive stops, its internal temperature detecting

program will be activated to stop the fan or let the fan

continue to run according to the IGBT’s temperature.

1: The fan operates continuously.

The fan operates continuously after the drive is switched

on.

F9.09 Unit of Acc/Dec time

Range: 0. 1【0】

F9.09 decides the unit of Acc/Dec time.

0: Second

1: Minute

This function is active for all the Acc or Dec process

except Jogging process.

Up to 60 hours’ Acc/Dec time can be set, suitable for the

application with a requirement of long Acc/Dec time.

Note

It is recommended to select “second” as the unit.

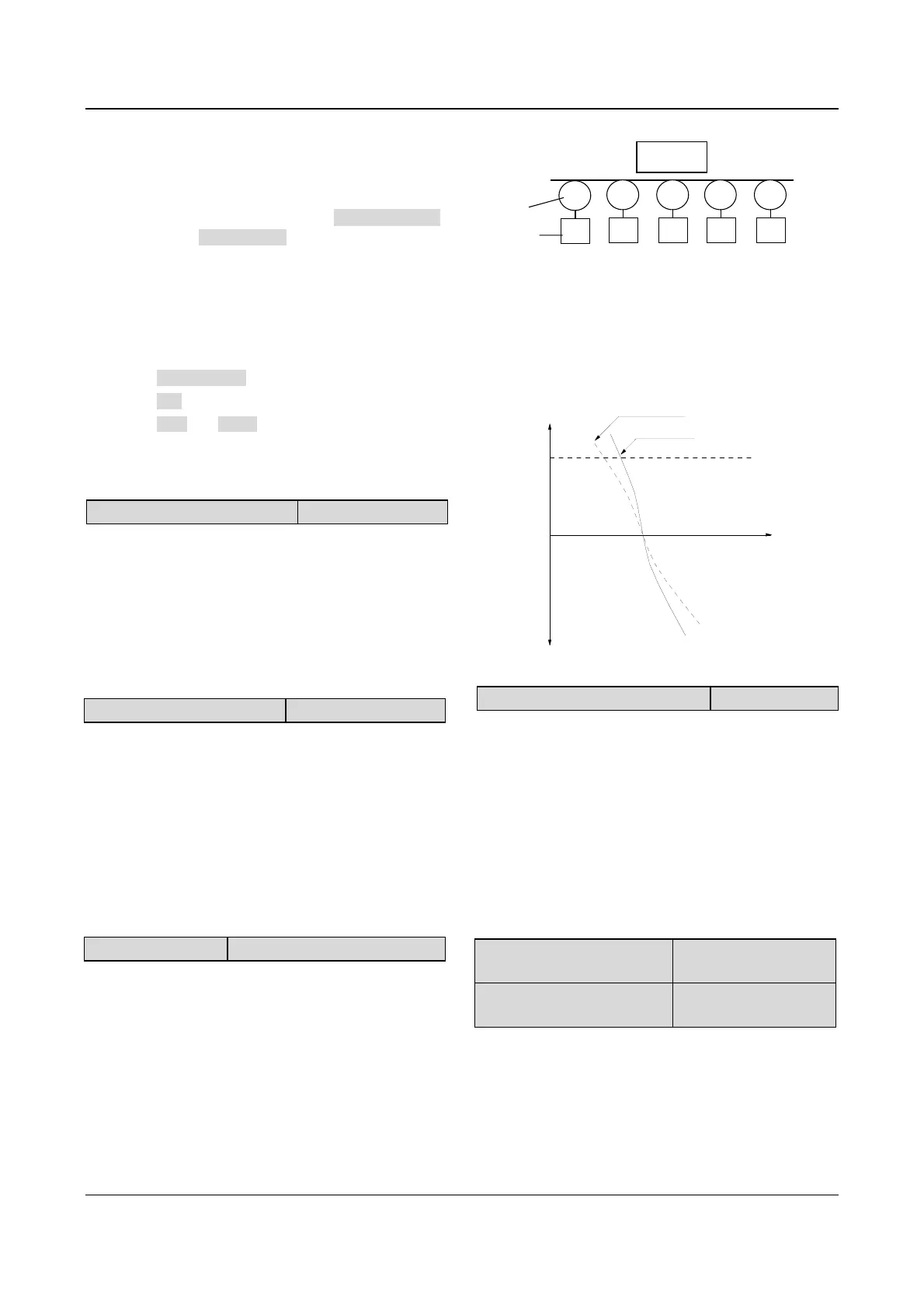

F9.10 Droop control

Range:0.00~10.00Hz【0.00Hz】

When several drives drive one load, the function can

make the drives share the load equally. An example is

shown in Fig. 5-65, 5 drives drive one conveying belt of

5 motors.

Drives

Motor

Belt

1

2 3 4 5

Load

Fig. 5-65 Droop control

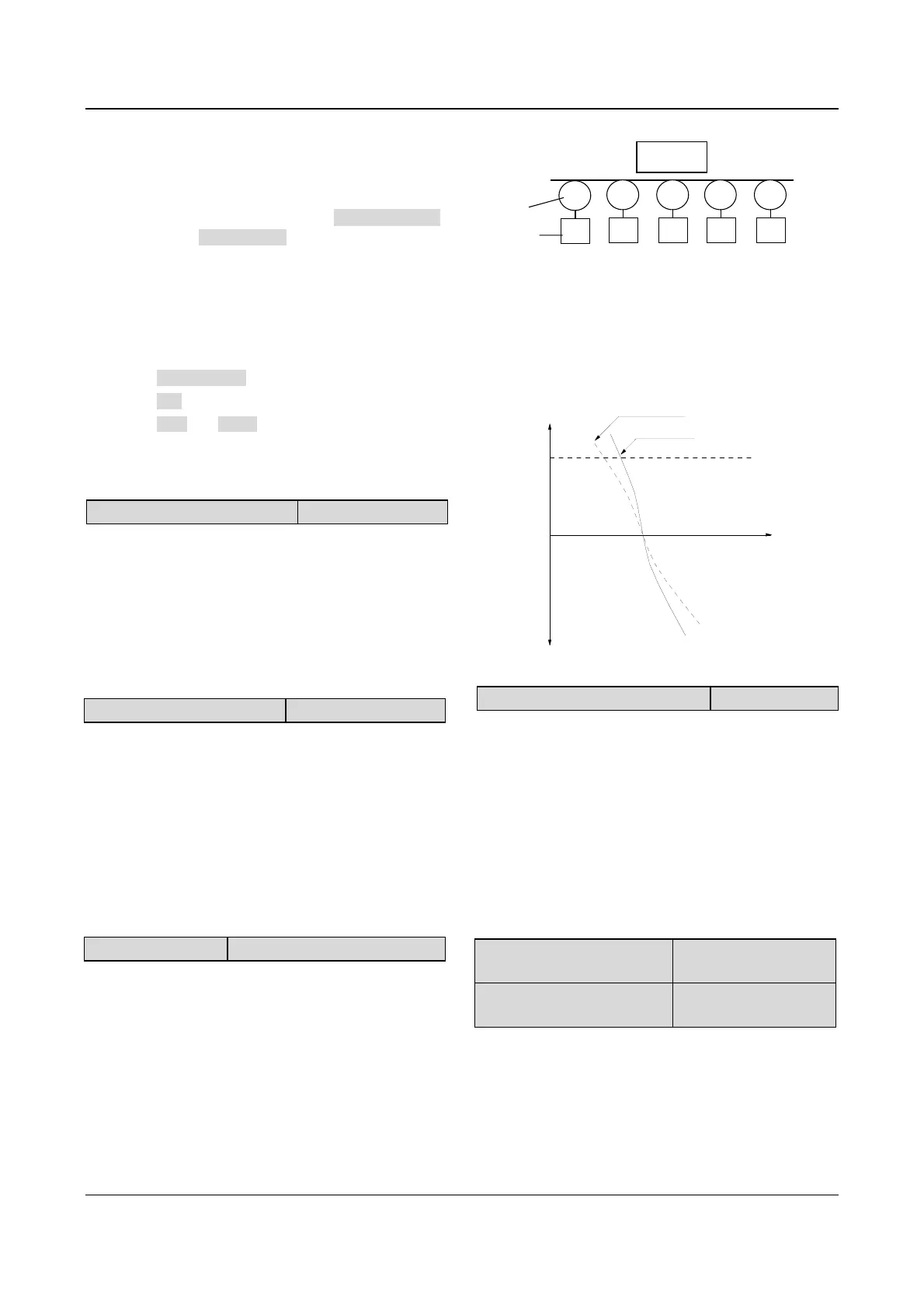

When the load of one drive is heavier, this drive will

reduce its output frequency to shed part of the load

according to the settings of F9.10. You can increase the

setting gradually when testing. The relationship between

the load and the output frequency is shown in Fig. 5-66:

o

Torque

Rated

torque

Synchronuous speed

Droop control

No droop control

Speed

Fig. 5-66 Droop control

F9.11 Overshoot enabling

Range:0. 1【1】

When the AC supply voltage is lower than 85% of rated

load for a long time or the drive has driven a heavy load

for a long time, the drive can increase its output voltage

by increasing the utilization rate of DC bus voltage.

F9.11 decides whether to enable the overshoot function.

0: disabled

1: enabled

Note:

When overshoot function is enabled, output current

harmonics will increase.

F9.12 Threshold of

zero-frequency operation

Range: 0.00~650.00Hz

【0.00Hz】

F9.13 Hysteresis of

zero-frequency operation

Range: 0.00~650.00Hz

【0.00Hz】

F9.12 and F9.13 are used to set the zero-frequency

operation hysteresis.

Take CCI current reference for example, see Fig.5-67:

Starting process

After the running command is sent out, the motor will

start and accelerate to the frequency corresponding to

Loading...

Loading...