Chapter 5 Parameter Introductions 75

EV2000 Series Universal Variable Speed Drive User Manual

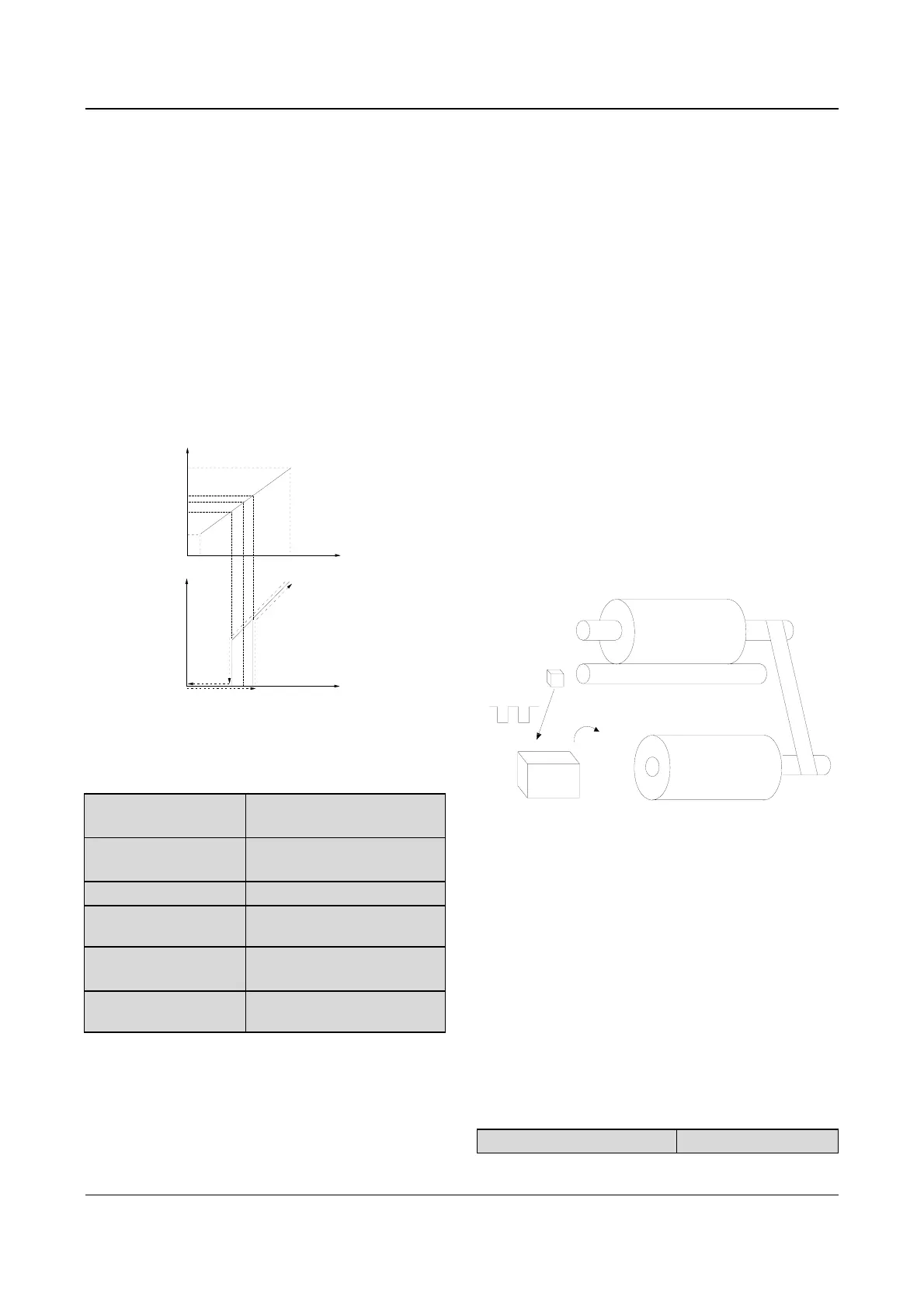

the CCI input current until CCI input current reaches or

exceeds the preset value of Ib, or the preset frequency

reaches fb.

Stopping process:

The drive will not stop immediately when the CCI input

current is reduced to Ib. It will stop its output when the

CCI input current drops to Ia and the corresponding

frequency is fa.

“fa” is the zero-frequency operation threshold defined by

F9.12. “fb-fa” is the hysteresis of zero-frequency

operation defined by F9.13.

This function can enable the drive to enter dormant state

so as to save energy, besides, the drive will not start at

the threshold of zero-frequency operation if the

hysteresis is set properly.

0

Actual

frequency

setting

Primary frequency setting

fa fc fb

CCI current input

Imax

Imin

Ib

Ia

Ic

Fmin

Fmax

fa: Zero frequency threshold

fb: fa+ zero freq. hysteresis

fc: Freq. corresponding to Ic(CCI input)

primary frequency setting

Fig. 5-67 Hysteresis of zero-frequency operation

F9.14 Preset length

Range:0.000~65.535km

【0.000km】

F9.15 Actual length

Range:0.000~65.535km

【0.000km】

F9.16 Rate of length

Range:0.001~30.000【1.000】

F9.17 Correction

coefficient of length

Range:0.001~1.000【1.000】

F9.18 Perimeter of shaft

Range:0.01~100.00cm

【10.00cm】

F9.19 Number of pulses

per revolution

Range: 1~9999【1】

This group of parameters are used for fixed length

control.

The drive inputs counting pulses via terminals (X7 or X8,

defined as function 44), and calculate length according

to the number of pulses per revolution (F9.19) and

perimeter of shaft (F9.18).

Calculated length

=Number of pulses÷number of

pulses per revolution

×perimeter of shaft

The calculated length can be corrected through F9.16

(times of length) and F9.17(correction coefficient of

length, and the corrected length is the actual length.

Actual length

=calculated length×F9.16÷correcting

coefficient of length

When actual length(F9.15)

≥preset length(F9.14), the

drive will send out a STOP command to stop the drive.

When the drive restarts, it needs to clear or modify the

actual length (F9.15), otherwise the drive will not start.

Note:

The actual length (terminal Xi is defined as No.39 function)

can be cleared by multi-function input terminal. The actual

length can be calculated only after this terminal is

disconnected.

Actual length (setting of F9.15) will be saved after power

off automatically.

Function of stopping at fixed length is disabled if F9.14 is

set to 0, but the calculated length is still effective.

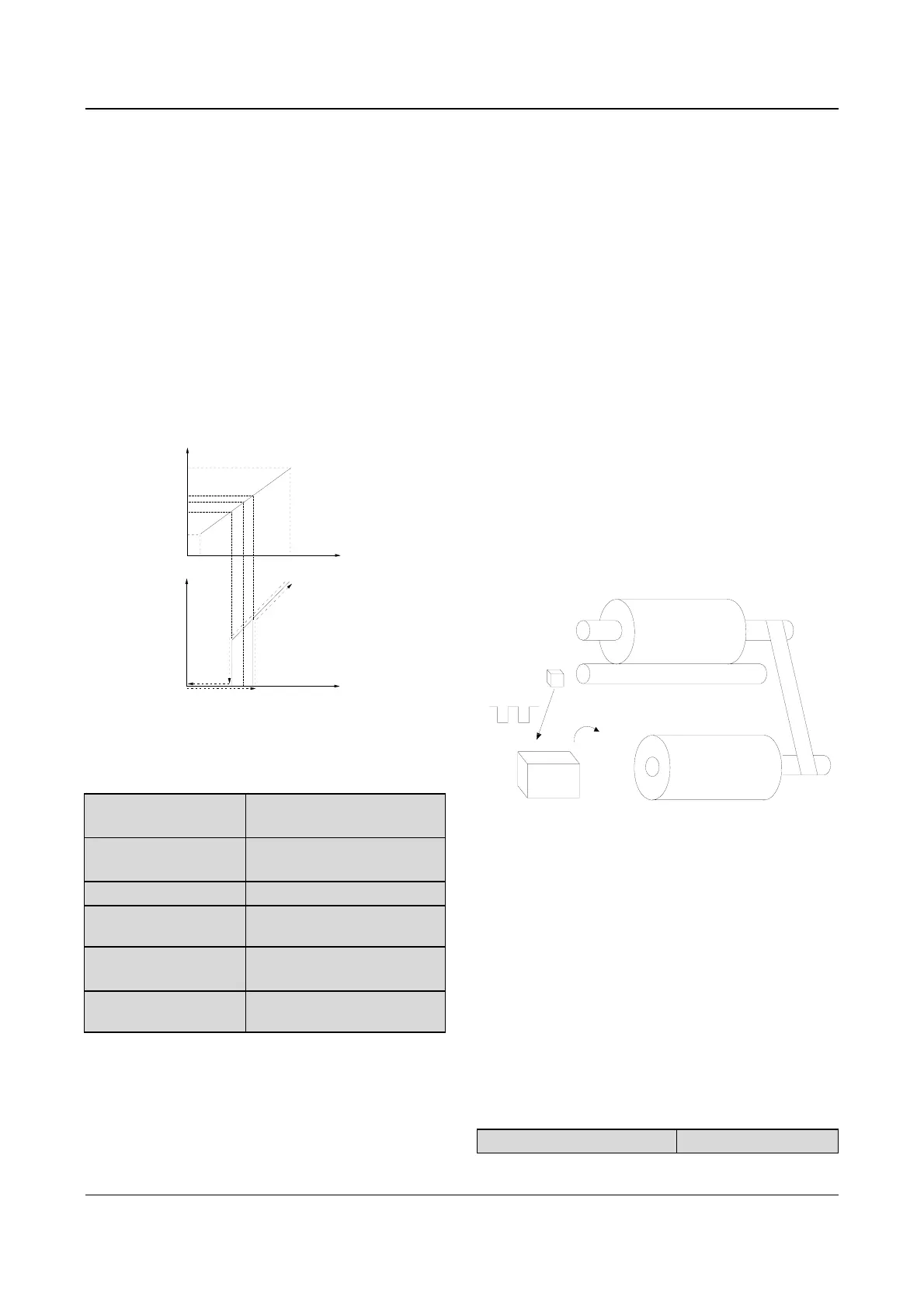

An example of stopping the motor at fixed length:

Drive

Motor

Spindle

Speed measuring shaft

Speed

sensor

Fig. 5-68 Fixed length control application

In Fig. 5-68, a drive drives a motor that rotates a spindle

via a conveyor belt. Speed measuring device measures

the line speed of the spindle and send the speed signal

to the drive in the form of pulses. The drive will count the

pulses and calculate the actual length. If the actual

length is longer than the preset length, the drive will stop

the motor automatically. The operator can remove the

spindle and close the terminal that is defined as function

39 to clear the length, and then restart and produce the

next spindle.

Note:

Functions of stopping the motor at a fixed length are only

valid for the drive of 45kW or below.

F9.20 Trip-free operation

Range:0. 1【0】

Loading...

Loading...