Liquiphant M FTL51C

Endress+Hauser 13

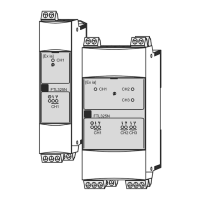

Electronic insert FEL57 (PFM)

Power supply Supply voltage: DC 9.5 to 12.5 V

Current consumption: 10 to 13 mA

Power consumption: < 150 mW

Reverse polarity protection

Electrical connection Two-wire connection for separate switching unit

The check is activated and monitored at the switching unit.

The twin-core connecting cable (instrument cable) with a cable resistance of 25 per core is

connected to the screw terminals (conductor cross-sections 0.5 to 2.5 mm / 0.02 to 0.1 in) in the

connection compartment. Protective circuits against reverse polarity, HF influences and overvoltage

peaks are installed.

Maximum cable length up to 1000 m (3281 ft).

A shielded connecting cable is recommended in the event of strong electromagnetic interference. Here

the shielding must be connected to the sensor and the power supply.

For connecting to Endress+Hauser switching units

Nivotester FTL320, FTL325P, FTL370, FTL372,

FTL375P (also with proof test).

Output signal jump of the PFM signal from high to

low frequency when sensor is covered. Switching

between minimum/maximum safety in the

Nivotester.

Additional function “cyclical checking”:

After interruption of the power supply,

a test cycle is activated

which checks the sensor and electronics

without any change in level.

Approved for overfill protection acc. to WHG

(German Water Resources Act).

The following can be switched at the electronic

insert:

– Standard

(STD):

simulation approx. 8 s

tuning fork exposed – covered – exposed.

For proof testing, the Nivotester tests the

sensor's level notification function.

– Extended (EXT):

Simulation approx. 41 s: tuning fork exposed –

covered – alarm – exposed.

For proof testing, the Nivotester tests the

sensor's level notification function and fault

notification (alarm) function.

L00-FTL5xxxx-04-05-xx-en-003

Loading...

Loading...