Frontier Gas Heat – PN 10-2027 – June 2018 16

ZONE PURGING:

Valves to isolate and purge individual zones should be installed according to good piping practices.

EXPANSION TANK SIZING: The type and size of expansion tank depends on the total system water volume. The

EK-1 Frontier contains 2-1/2 gallons of water and the EK-2 Frontier contains 4 gallons of water.

NOTICE: Sizing must

consider

cold start and hot operation due to system concepts of energy recovery and rapid heat up.

FILLING WITH WATER, VENTING, and PURGING

When piping is completed and all accessories installed the Converter and piping should be filled with water. The

Converter purges itself of air when properly installed.

NOTICE: AIR VENT CAP MUST REMAIN OPEN. Vent cap should

be removed and kept in a safe location. Each zone should be purged until a steady stream of water without air passes out

of purge hose. Vent all radiation.

NOTICE: DO NOT START BURNER UNTIL CONVERTER AND SYSTEM ARE FULL OF WATER. Fill to normal cold

system pressure, 10 to 12 psi on pressure gauge. Before placing system in operation, carefully check for leaks throughout

system. Tighten pipe joints, circulator flanges, check gaskets, etc., as needed.

BOILER WATER TREATMENT

Addition of boiler water treatment is recommended to reduce lime buildup inside the boiler. Energy Kinetics

recommends addition of one quart of 8-Way Boiler Treatment per 30 gallons system water. 8-Way Boiler Treatment is

recommended to treat water up to medium hardness. Call Energy Kinetics for more details about boiler water treatment

and about hard water conditions.

ANTI-FREEZE

Only non-toxic antifreeze (such as Propylene Glycol) should be used if adding anti-freeze to a System 2000 boiler.

Hard water should not be used in combination with generic antifreeze. Energy Kinetics supplies a quality inhibited

Propylene Glycol anti-freeze with orange dye and an antifoam agent. 8-Way Boiler Treatment can be added to Energy

Kinetics anti-freeze and is recommended in areas of medium water hardness.

NOTICE: Thoroughly clean system prior

to adding antifreeze.

TSP is recommended for removing flux and other oil based compounds. Once system has been

cleaned and flushed, then add antifreeze to obtain approximately a 30% by volume mixture of antifreeze in water. Call

Energy Kinetics for assistance in calculating how much anti-freeze to add to system.

WINTERIZING

NOTICE: If the SYSTEM 2000 Boiler may be exposed to freezing temperatures, such as a vacation home shut down

for the winter, then anti-freeze should be added to the boiler water. When a home is winterized by draining all domestic

water piping, then the SYSTEM 2000 Boiler must be protected. It is not recommended to drain the SYSTEM 2000 Boiler,

because introducing air into the boiler can cause rusting inside the boiler shell and also because the Energy Converter has

a spiral water passage that cannot be completely drained of water. When draining the domestic water piping system, be

sure to drain the domestic side of the plate heat exchanger. If the hydronic system will not be drained, then add enough

anti-freeze to protect the entire hydronic system including the boiler, piping, radiation, circulators, etc. If the hydronic

system will be drained, then add shut off valves to isolate the boiler and add anti-freeze to the boiler only, as follows. Drain

water from the boiler and then add anti-freeze to the boiler. Refill boiler with water and run boiler circulator through the

bypass to distribute antifreeze within boiler. Propylene Glycol in water will provide the following freeze protection: 30%

down to +8

o

F, 40% to -8

o

F, 50% to -27

o

F. Energy Kinetics recommends using 30% anti-freeze to obtain the best boiler

performance. Use over 30% anti-freeze only if lower temperature freeze protection is mandatory.

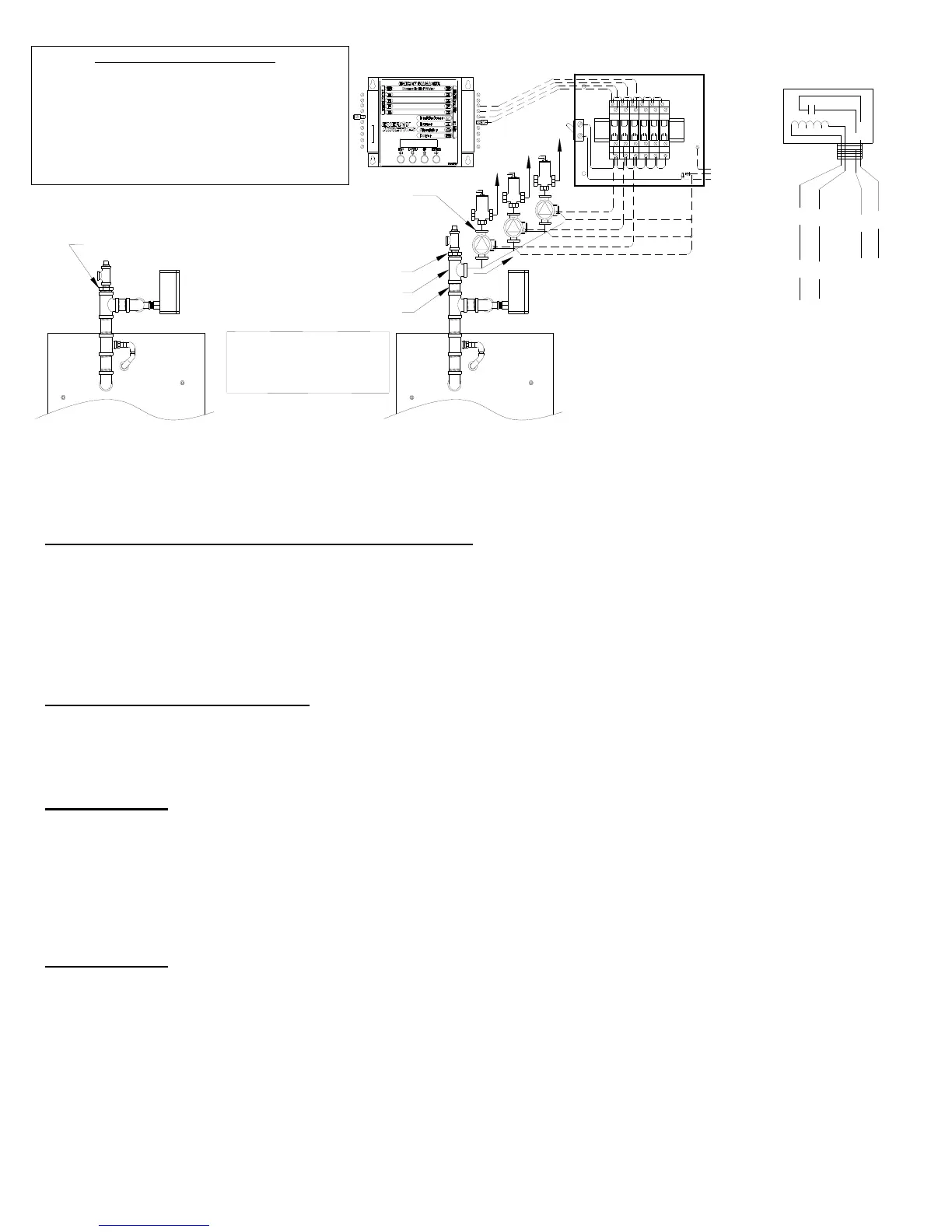

ORANGE

YELLOW

WHITE / YELLOW

WHITE/BLUE

EK# 10-0412-RIB (RIB# 2421C)

24V/120VAC Relay SPDT

24VAC

Coil Leads

To Manager,

Zx & 24V

N/O Contact

Leads

To CIRC,

Power To L1

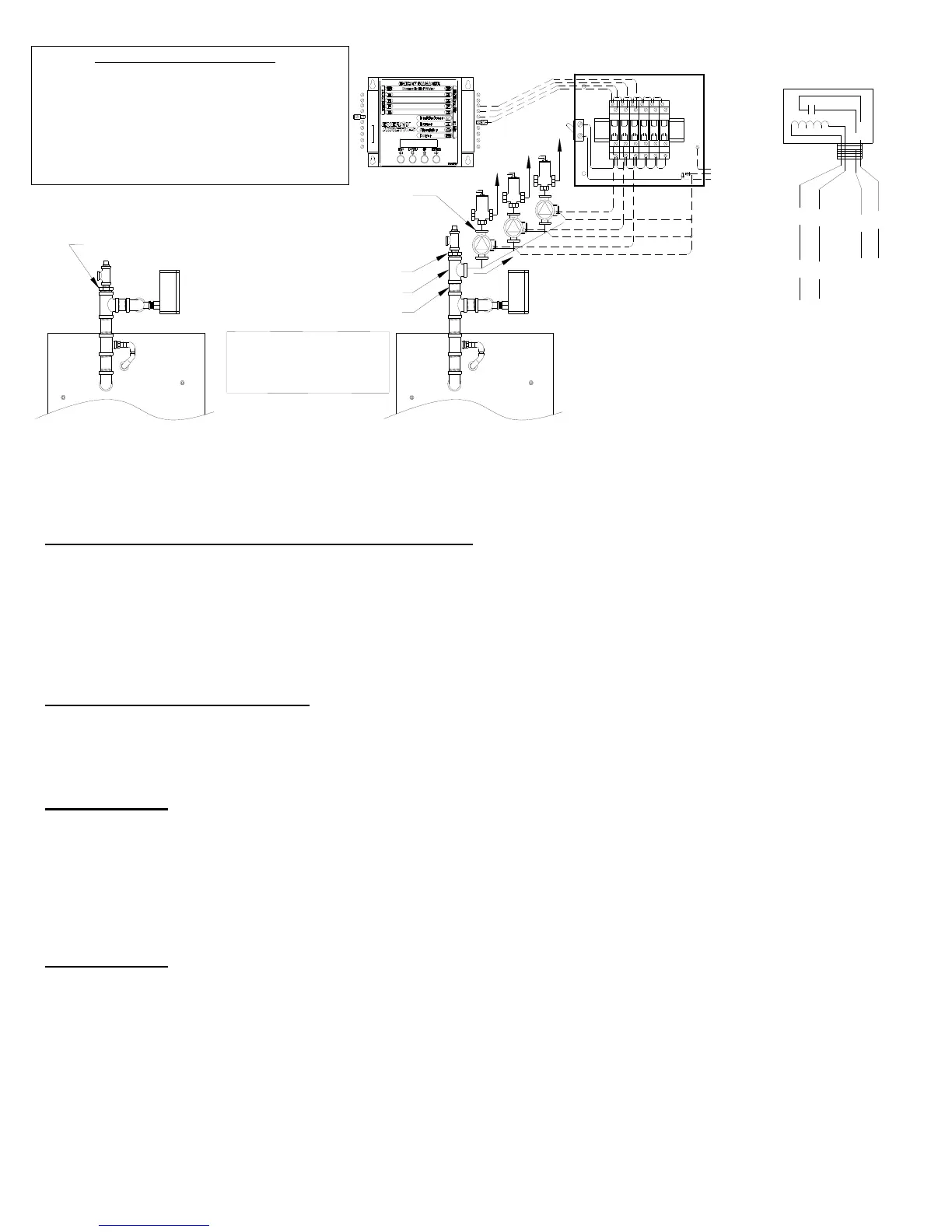

Full Size Tee (added)

Nipple (added)

Bushing (moved)

1. Remove bushing installed at

factory from boiler supply.

2. Install a nipple (not supplied)

into the existing tee.

3. Install a tee (not supplies) on

to the new nipple.

4. Reinstall the bushing into the

new tee.

SUPPLY

Ground

Neutral

Line

120 VAC

Frontier Boiler Supply Piping

Modified piping for Zone

Circulators.

Looking from rear of boiler.

Circulators w/IFC or Circulators and Flow Checks

(Supply Side Preferred*)

*Circulator may be Installed Return Side

System Manager

5 Zone Circulator Relay Kit

P/N: 10-0412R-5 Shown

ZONE CIRCULATOR RELAY KITS

TO ACTIVATE EACH CIRCULATOR, USING The

SYSTEM MANAGER'S 24VAC OUTPUTS, USE ONE OF

ENERGY KINETICS MULTIPLE ZONE RELAY KITS.

5 ZONE RELAY KIT P/N: 10-0412R-5

10 ZONE RELAY KIT P/N: 10-0412R-10

15 ZONE RELAY KIT P/N: 10-0412R-15

OR INDIVIDUAL 24V RELAY(S) (EK#10-0412-RIB RIB

RELAY OR EQUIVALENT)

Bushing (Installed at Factory)

TEMP. SENS.

R

S

B

A2

A1

B2

CIRC

B1

24VAC

IND

T3

T1

T2

THW

T4

Z1

Z2

Z3

Z4

ZHW

Loading...

Loading...