Frontier Gas Heat – PN 10-2027 – January 2016 34

Annual Tune Up & Inspection

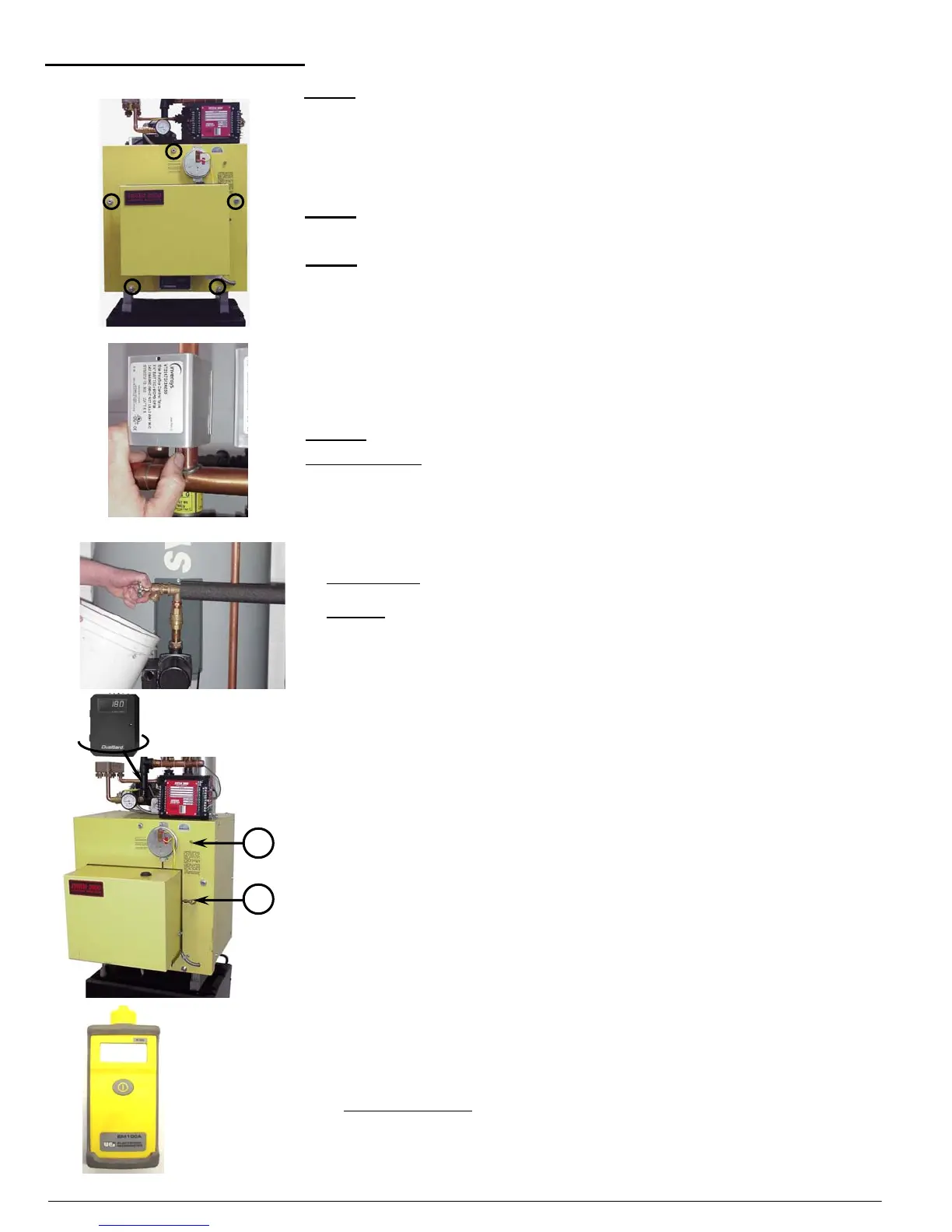

Step 10 Start Burner & Check Safety Functions.

Check & Record: Air box cover must be in place before testing.

Refer to burner manual for recommended settings.

1. Check manifold pressure with the burner running by installing a hose barb fitting

in the combination gas valve outlet pressure tap. Adjust valve regulator if

necessary so the reading is 3.5”w.c. for either LPG or natural gas.

2. Draft Loss: A difference of 0.04” or less between flue box (1) and “over fire” test

port (2).

Sidewall Vent: Draft over fire of -0.10” to -0.12”wc after 15 minutes of continuous

burner operation.

Chimney: Draft over fire should be -0.02” to -0.12”w.c.).

3. Check CO

2

/O

2

at over fire test port (2) Natural: CO

2

:8.6%-9.2%, O

2

5.5%-4.5%

LPG: CO

2

:9.7%-10.7%, O

2

6.0%-4.5%

4. Stack Temp: 350º-450º F. (at stack or flue box port)

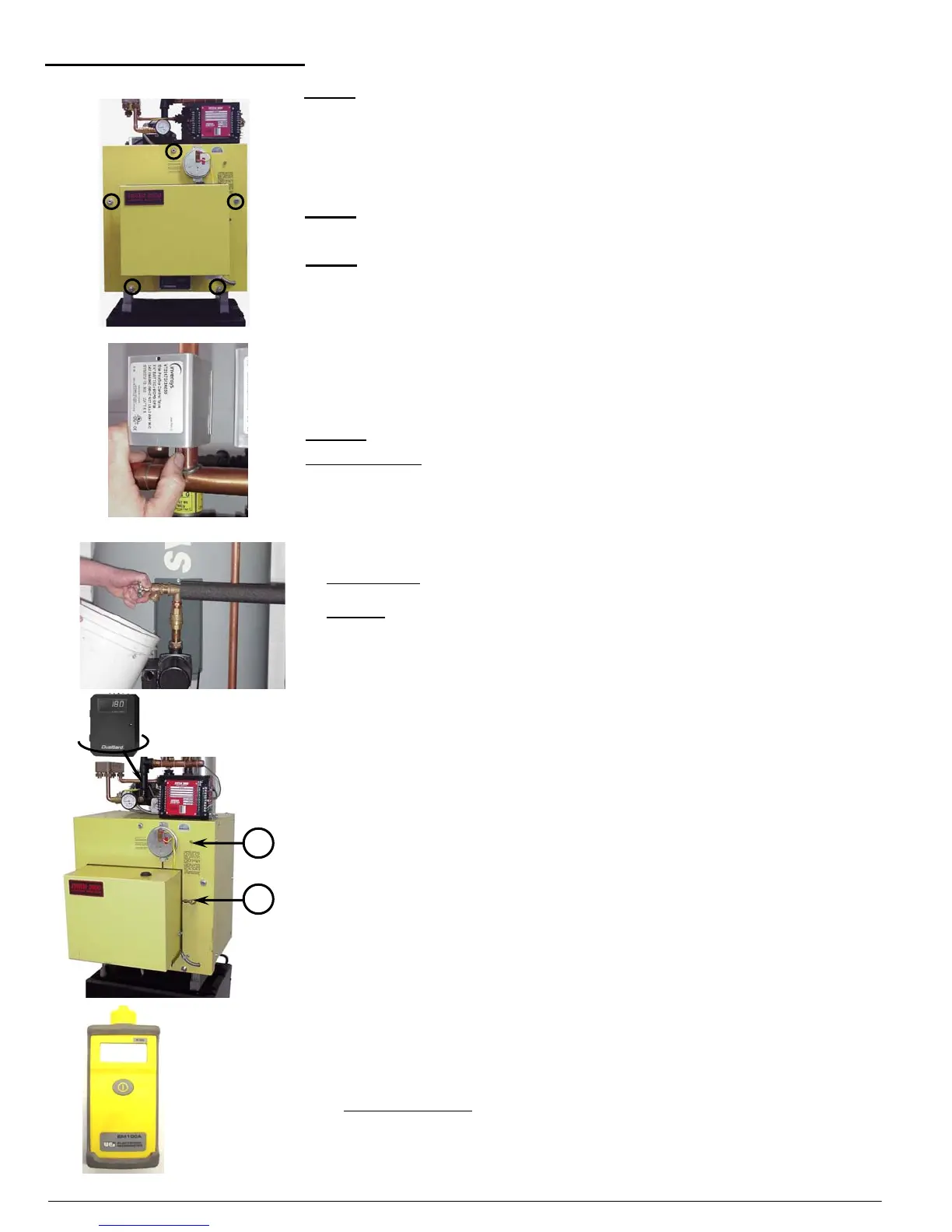

5. Check CO: 400 ppm Max Air-free (Refer to installation manual for Air-free

method of measuring CO).

6. Verify DualGard set to 205º/215º F.

7. Test Safety High Limit operation:

a. Remove all heat and hot water calls (No input lights on left side of manager).

b. Turn System switch off, then remove red sensor lead from the left side quick

connect.

c. Restore power. The E100 code will flash on the manager’s display, and the

burner should start momentarily.

d. At approximately 205

o

F to 215

o

F, the high limit aquastat should shut off

burner.

8. Verify flame failure lockout of Carlin 60200FR burner control

a. Connect hose from manometer to hose barb fitting in the combination gas

valve outlet pressure tap.

b. Close the main manual gas valve and turn the combination gas valve knob to

ON.

c. Turn on power to System 2000 boiler and adjust a thermostat to call for heat.

d. Burner motor will start. The burner control will run for 30 seconds (pre-purge),

then start the ignitor. Approximately one second later, the combination gas

valve will open. (The manometer should show almost no pressure, because

the main manual gas valve is closed.)

e. After 4 seconds, the burner control will lockout and turn on the red LED. The

ignitor will shut off and the gas valve will close. Turn off power and adjust the

thermostat to stop the call for heat.

If lockout does not occur, replace the burner control.

9. Sidewall Vent Only:

a. Remove power from the inducer. (option switch 2 on a Digital Manager)

b. Start burner. Safety lock-out should occur in approximately 1 minute.

c. Restore power to the inducer.

Step 8 Check Zone Valves

Open/Close zone valves several times to see that they move freely.

Step 9 Backflush Plate Heat Exchanger

1. Close the valve underneath the domestic hot water circulator.

2. Open drain valve above the circulator to back flush the heat exchanger.

3. If domestic water supply is “hard” (lime), consider installing Scale Stopper (Item

no. 10-0650).

4. Set temperature feeding hot water tank (above heat exchanger) by adjusting the

ball valve below the bronze circulator. Adjust the ball valve with the burner running

and a continuous flow of hot water from a fixture. You should just be able to hold

your hand on the pipe.

Step 7 Close Front Cover

1. Install (3) upper nuts and washers.

2. Tighten nuts (5) uniformly.

3. Check and tighten (6) rear cover nuts.

4. Check Flue Pipe.

5. Check chimney base and clean if necessary

Digital

Manomete

1

2

3

4 5

1

2

Safety High

Limit

Loading...

Loading...