Frontier Gas Heat – PN 10-2027 – June 2018 9

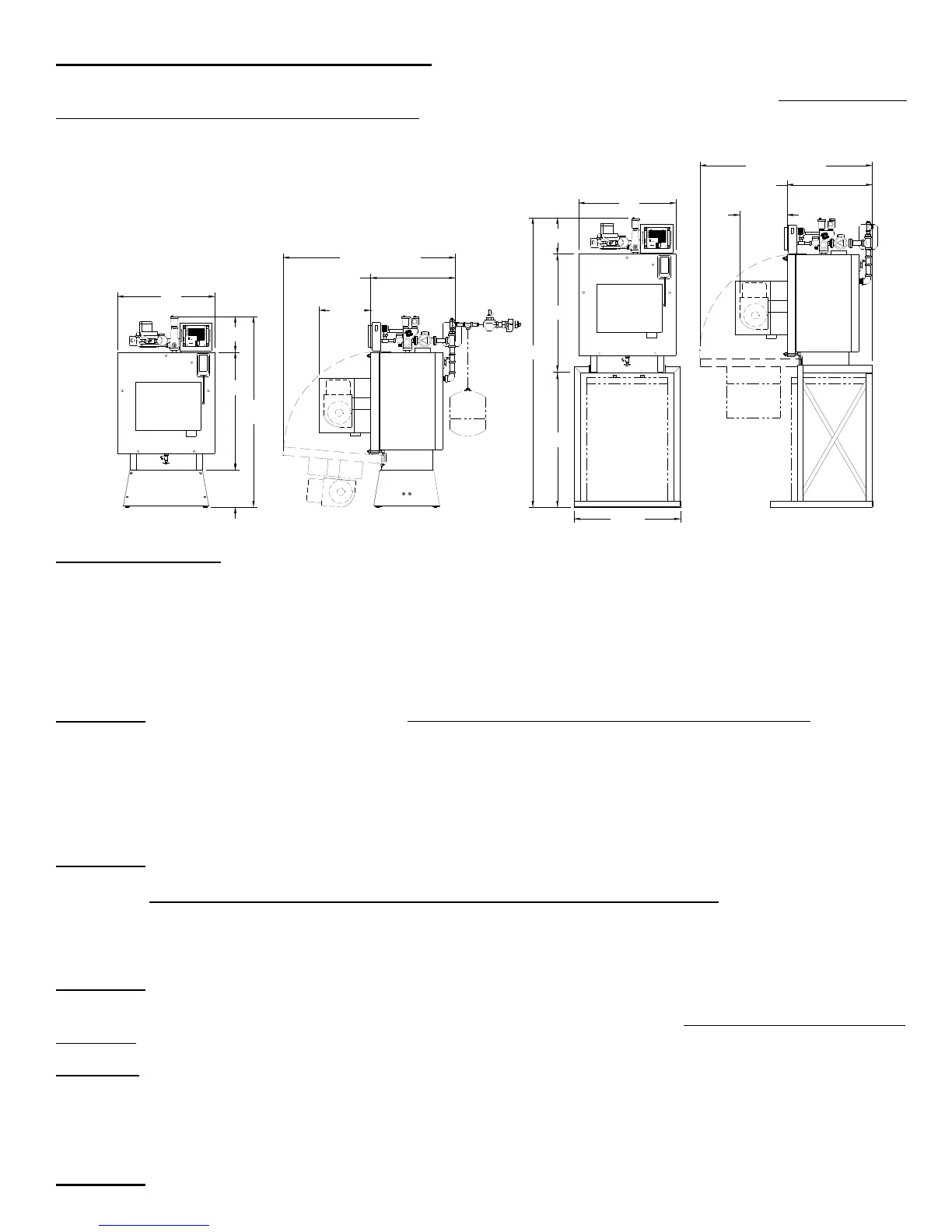

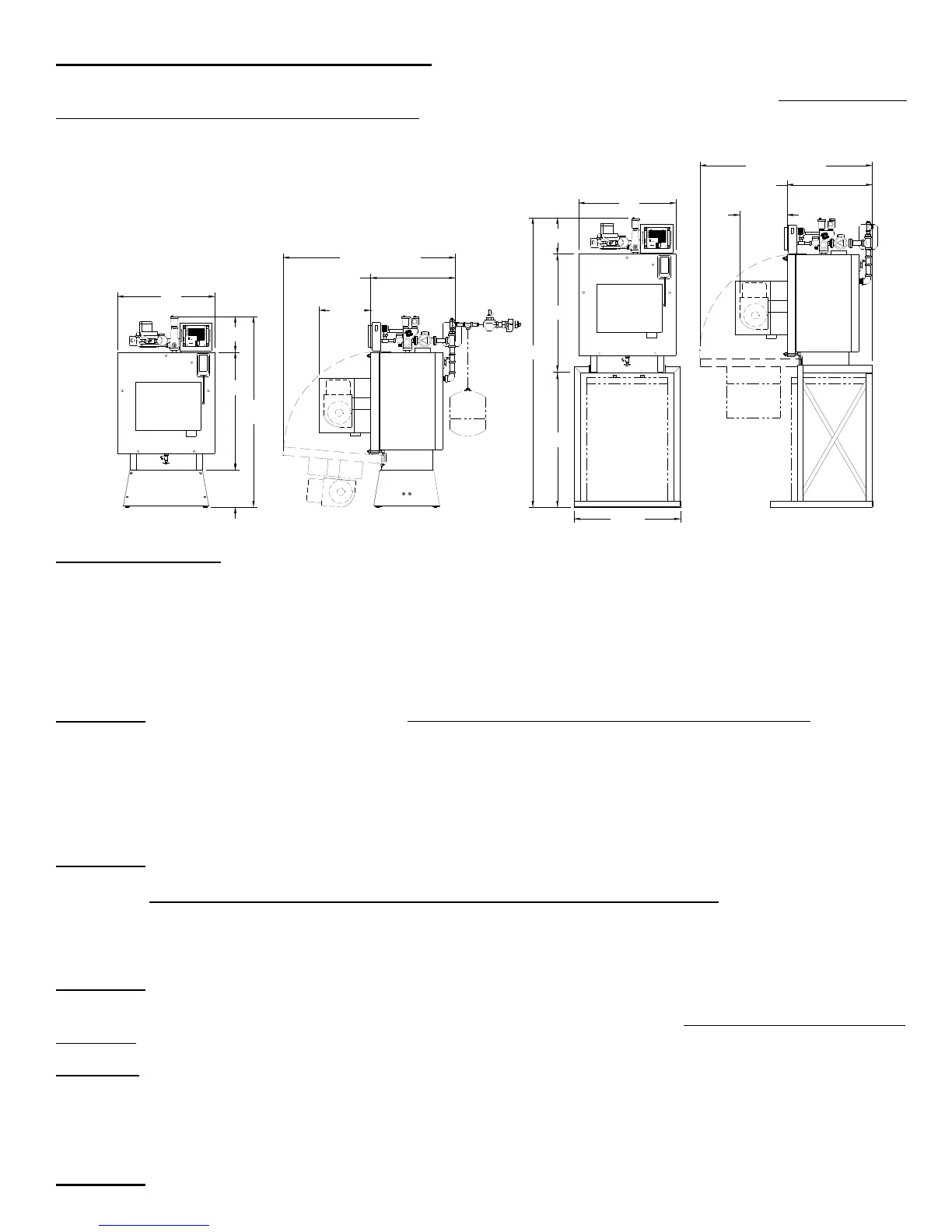

CLEARANCE for CLEANING and SERVICE

Installations should utilize one of Energy Kinetics boiler stands to provide a solid, level, and smooth foundation for the

boiler. NOTICE: Do not install on carpeting. Place the unit as near to the chimney or vent as possible allowing clearance

for front cleaning and service as shown in Figure 1B. If not using an Energy Kinetics supplied stand, provide a solid, level,

smooth, foundation with clearance for door opening and service. NOTICE: The stand must be level to allow for proper

venting of air from the boiler. The Frontier is manufactured with the BACK of the boiler higher than the front to assist in air

removal.

COMBUSTION AIR

The System 2000 Boiler must be installed in an area where adequate fresh air is available to support combustion. The

Frontier is provided with a sealed Air Box that can be piped to air outside the building. Piping of outside air directly to the

boiler is highly recommended because it completely isolates the boiler from the home environment, as well as greatly

reducing operating noise from the boiler.

Boiler with outside air piping: In modern houses with tight construction the connection of the Air Box to an outside air

source to provide combustion air is highly recommended. The outside air source must be located high enough above grade

to be at least 12” above expected snow accumulation.

WARNING: For systems with sidewall venting, combustion air piping from outside the building is required. The

Energy Kinetics sidewall vent kit contains specific instructions for installation that must be followed. Combustion air may be

supplied through PVC pipe. For EK-1 use, 2" pipe up to 20 feet in length with up to (5) 90-degree elbows. For EK-2 use, 3"

pipe up to 20 feet in length with up to (5) 90-degree elbows. A total equivalent length of 45 feet is allowed. Each 90-degree

elbow is the equivalent of 5 feet of straight pipe. For example, if three 90-degree elbows are used, then the length of pipe

run may increase to 35 feet. An unglued or Tek-screw joint allows the door to swing down when the air inlet pipe is

disconnected.

WARNING: Modern buildings of tight construction, as well as the operation of attic and exhaust fans, kitchen ventilation

systems, clothes dryers or fireplaces may create conditions of unsatisfactory combustion or venting. Provisions must be

made to use combustion air that communicates with a well-ventilated attic or with the outdoors (such as using a louver or

grate). The opening should have a free area of not less than one (1) square inch per 4,000 BTU per hour of the total input

rating.

Boiler without outside air piping:

WARNING: The confined space shall be provided with two permanent openings, one near the top of the enclosure and

one near the bottom. Each opening shall have a free area of not less than one square inch per 1,000 BTU per hour of the

total input rating of all appliances in the enclosure, freely communicating with interior areas having adequate infiltration from

the outside.

VENTING

When connecting the Gas Heat version of the Energy Kinetics SYSTEM 2000 boiler to gas vents or chimneys, all vent

installations shall be in accordance with Part 7, Venting of Equipment, of the National Fuel Gas Code, ANSI Z223.1/NFPA

54, or Section 7, Venting Systems and Air Supply for Appliances, of the CAN/CGA B149, Installation Codes, or applicable

provisions of the local Building Codes. Vent connectors serving appliances vented by natural draft shall not be connected

into any portion of mechanical draft systems operating under positive pressure.

WARNING: No solid fuel appliance or fireplace should be installed in a flue common with this heating appliance.

Fi

ure 1B

Boiler Clearance for Clearin

and Service

NOTE:

Tank Stand

Allows The Boiler

To Be Mounted

Over Top Of a 40

Gal Lo-Boy Tank.

NOTE:

All piping

(hydronic, gas &

inlet air) must

allow clearance

for door opening.

CAUTION

Lebanon, New Jersey

ERGY

ETICS

SYSTEM 2000

B

TEMP. SENS.

S

R

T4

T2

T1

THW

A2

A1

T3

EN

KIN

1

2

4

3

BURNER

CIRCULATOR

1

2

HOT WATE R

4

INDUCER

3

IND

B1

B2

CIRC

ZHW

Z1

Z4

24VAC

Z3

Z2

ENERGY MANAGER

CAUTION

Lebanon, New Jersey

ERGY

ETICS

SYSTEM 2000

B

TEMP. SENS.

S

R

T4

T2

T1

THW

A2

A1

T3

EN

KIN

1

2

4

3

BURNER

CIRCULATOR

1

2

HOT WATER

4

INDUCER

3

IND

B1

B2

CIRC

ZHW

Z1

Z4

24VAC

Z3

Z2

ENERGY MANAGER

24"

9"*

17"**

30"

9"

48"*

56"**

EK1: 41" / EK2: 49"

12-3/4"

EK1: 21-1/2"

EK2: 29-1/2"

29-1/4"

73"

30"

34"

24"

9"

EK1: 41" / EK2: 49"

11-5/8"

EK1: 21-1/2"

EK2: 29-1/2"

* Height of Frontier on a Low Profile Base

** Height of Frontier on a Standard Boiler Base

Loading...

Loading...