Frontier Gas Heat – PN 10-2027 – June 2018 23

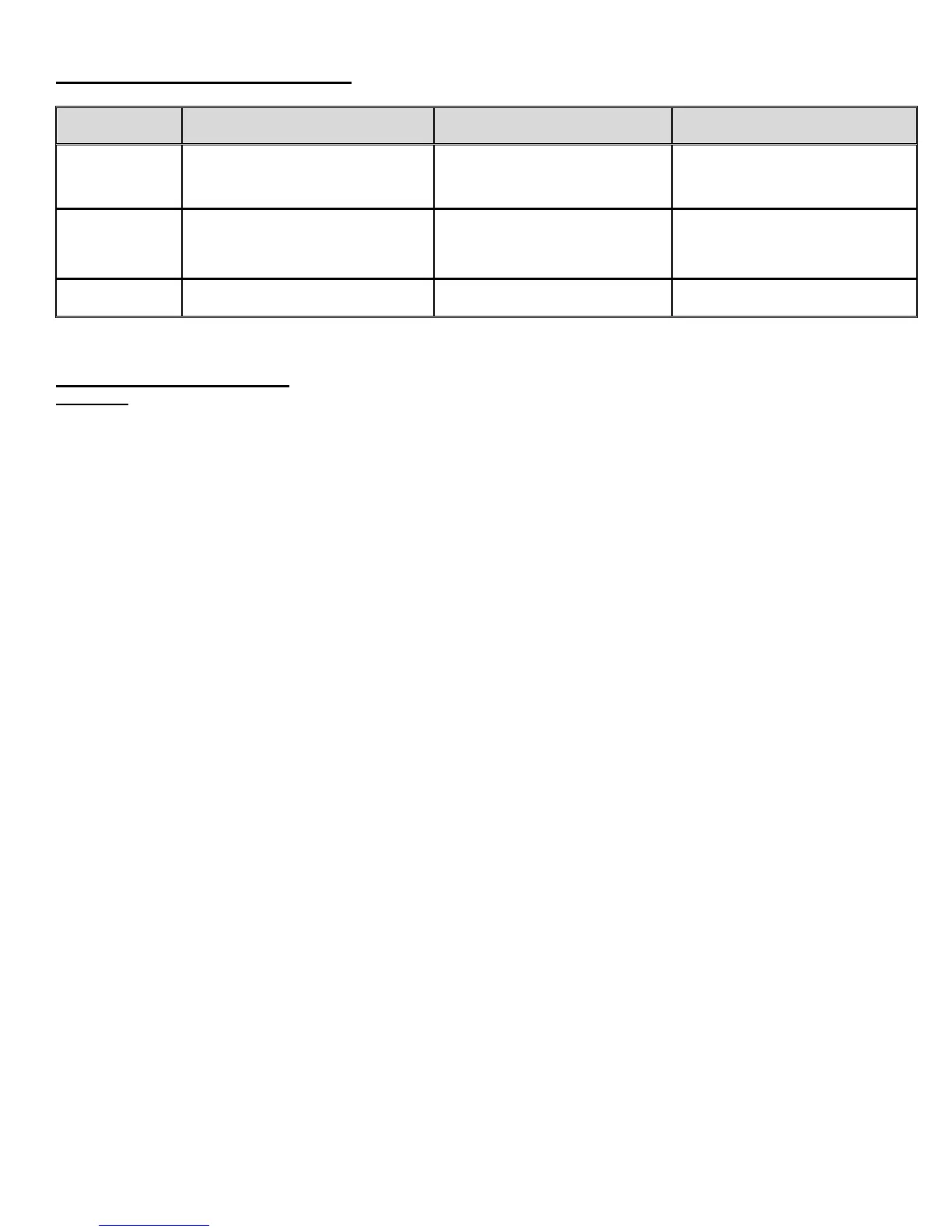

HYDRONIC CONTROL SETTINGS

Configuration Control Model No. Normal Setting

Frontier Boiler

Auto Reset High Limit

Auto Reset LWCO

Manual Reset Lock Out Temp

DualGard Model: 2450-1

Energy Kinetics PN: 10-0596

215

o

F Auto Reset High Limit

10

o

F Differential (215

o

/205

o

F)*

250

o

F Manual Reset Fixed Max

Frontier Boiler

w/Commercial

Kit

Auto Reset High Limit Aquastat

Manual Reset LWCO

Manual Reset Lock Out Temp

DualGard Model: 2450-2

Energy Kinetics PN: 10-0596-M

215

o

F Auto Reset High Limit

10

o

F Differential (215

o

/205

o

F)*

250

o

F Manual Reset Fixed Max

Domestic Hot

Water Tank

Tank Aquastat

(On Tank)

Energy Kinetics PN: 10-0414

‘Hot’, pointer points to 6 pm.

(To suit individual installation)

* Factory Setting

PREPARE FOR START UP

DANGER: MAKE CERTAIN THE FOLLOWING REQUIREMENTS HAVE BEEN SATISFIED BEFORE START UP:

1. The boiler and piping are completely filled with water.

2. Re-check wiring to ensure that it is correct and in accordance with appropriate wiring diagrams and codes.

3. Verify that proper gas orifice size is used.

4. Verify electrode and flame sense rod settings.

5. Verify the burner settings for air band position and head position

(see "Gas Burner Settings" Table).

6. Gas supply is connected to burner. Gas supply lines and shut-off valves are open.

7. Gas lines are purged.

8. Verify operating gas pressure at inlet of gas valve.

9. Adjust bypass valve on boiler side to heat exchanger ½ way open.

See #4 under “Gas Burner Operation”.

10. Flue pipe properly connected from unit to chimney. All joints are secured and sealed.

11. Combustion air supply is available and sufficient. (

See “Combustion Air”)

12. Punch a ¼” sampling hole in flue pipe as near to unit as possible in flue outlet and loosen 1/8” plug in front jacket (to

right of burner) for use as the overfire sampling location.

Loading...

Loading...