11

C048-725-30 Rev. B (01/2020)

4.4 4.4 Input ConnectionsInput Connections

WARNING! ELECTRICAL HAZARD

TO PROTECT PERSONNEL AND EQUIPMENT,

ENSURE ALL INPUT POWER FEEDS ARE NOT

ENERGIZED BEFORE INSTALLING THEM�

ELECTRICAL INSTALLATION SHOULD ONLY BE

PERFORMED BY QUALIFIED PERSONNEL WITH

PROPER TOOLS AND PROTECTIVE SAFETY

EQUIPMENT�

MAKE SURE THAT ALL FEEDER CABLES HAVE

HEAT SHRINK APPLIED PRIOR TO TERMINATION,

AND THAT NO-OXIDE COMPOUND IS APPLIED

TO ALL COPPER-TO-COPPER CONNECTIONS�

USE ONLY COMPONENTS AND CRIMPING TOOLS

APPROVED BY AGENCIES OR CERTIFYING

BODIES RECOGNIZED IN YOUR COUNTRY OR

REGION�

NOTICE:

Table 3. Electrical Termination Summary

TWO HOLE

LANDING

TYPE

HOLE/

STUD SIZE

CENTER

TO

CENTER

RECOMMENDED

TORQUE VALUE

Through Hole 3/8in 5/8in - 1in 145in-lbs

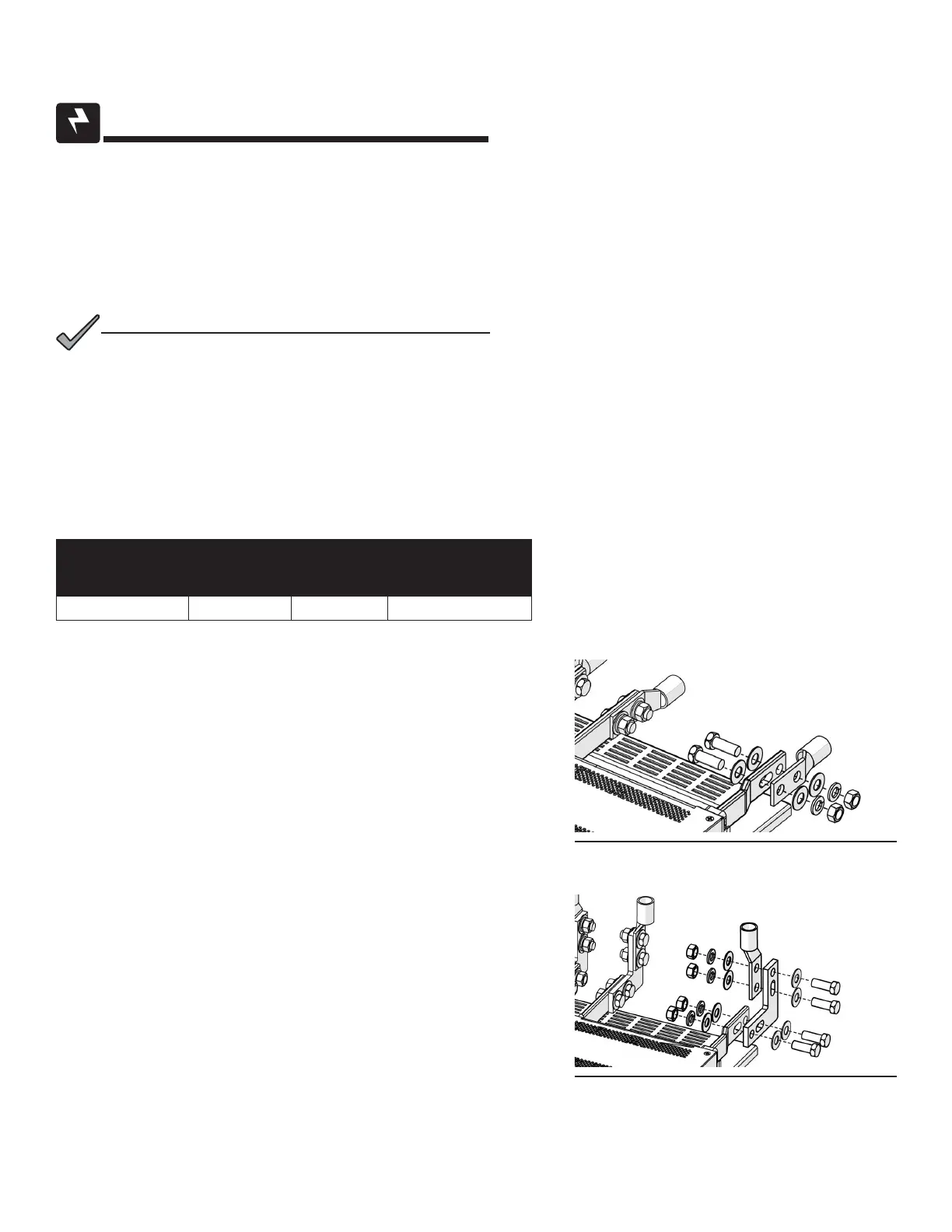

4.4.1 4.4.1 Straight Lug Input CongurationStraight Lug Input Conguration

(See Figure 9)

Step 1. Secure the HOT input cables lug(s) to the HOT input bus

bar(s) with the included 3/8”-16 x 1” hardware� Torque

the bolts to 145 in-lbs�

Step 2. Secure the RTN cable lug(s) to the RTN input bus bar(s)

with the included 3/8”-16 x 1” hardware� Torque the bolts

to 145 in-lbs�

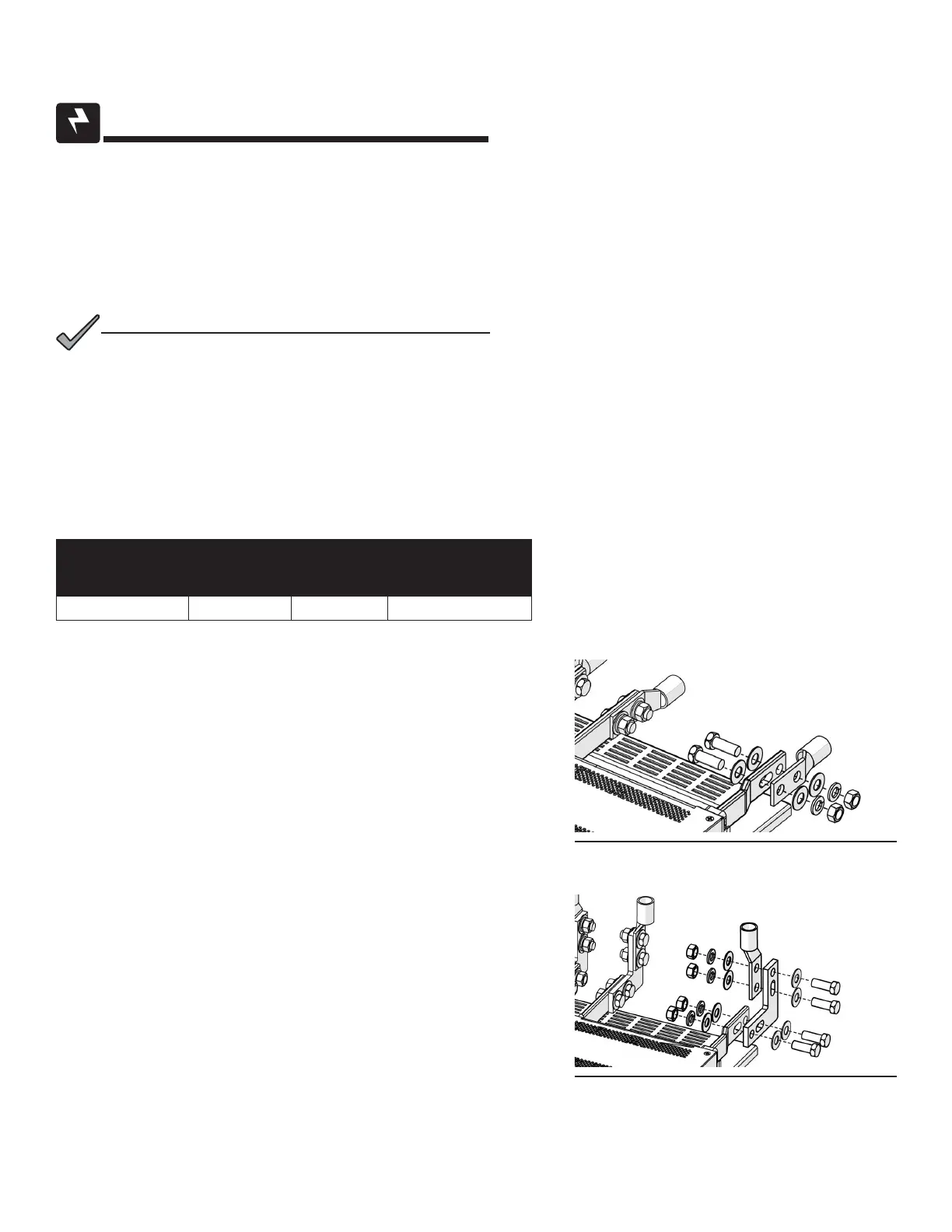

4.4.2 4.4.2 Optional 90 Degree Lug Input CongurationOptional 90 Degree Lug Input Conguration

(See Figure 10)

Step 1. Secure the 90 degree HOT input bus bar adaptor(s) to

the HOT input bus bar(s) with the included 3/8”-16 x 1”

hardware� Torque the bolts to 145 in-lbs�

Step 2. Secure the 90 degree RTN input bus bar adaptor(s) to

the RTN input bus bar(s) with the included 3/8”-16 x 1”

hardware� Torque the bolts to 145 in-lbs�

Figure 9. Straight Input Lug Installation

Figure 10. 90 Degree Input Lug Installation

Loading...

Loading...